Recover valuable lumber from slabs, and produce lap siding, crating, dunnage and more.

The powerful yet economically priced Cantek HR12E horizontal resaw can produce a cut up to 11.8” wide and 4.92” thick. Capable of handling material from 11.8” wide to 9.8” thick. The powerful 20HP motor makes easy work of even hard to cut wood material. The thin kerf 1” wide blade achieves optimum cut quality while maximizing material yield. The user-friendly controls and operation make will allow your resawing operation to get up to speed quickly. It is economically priced for the small to mid-sized operation looking to improve their efficiency and material yield.

Why Cantek HR12E Horizontal Band Resaw?

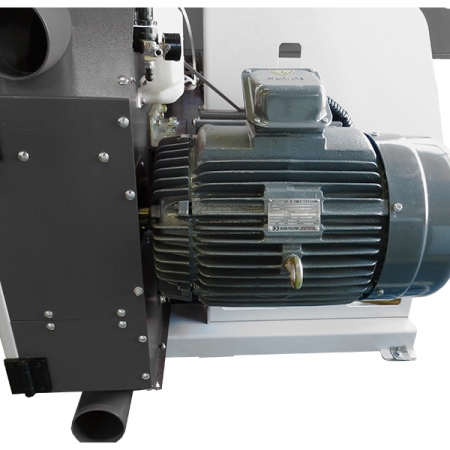

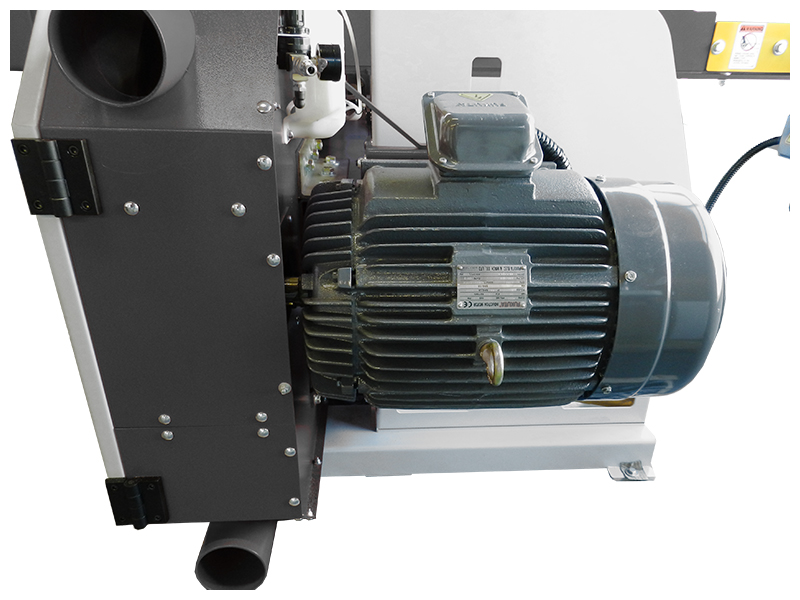

- Powerful 20HP saw motor capable of cutting through virtually any wood species with ease

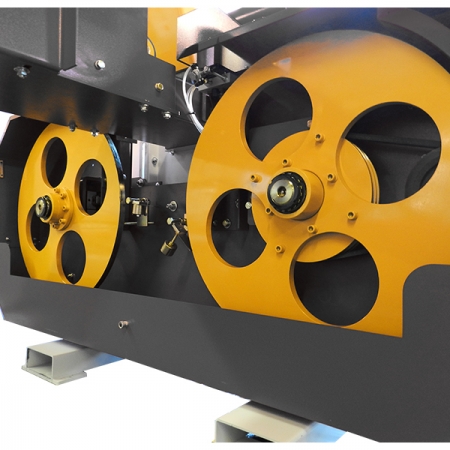

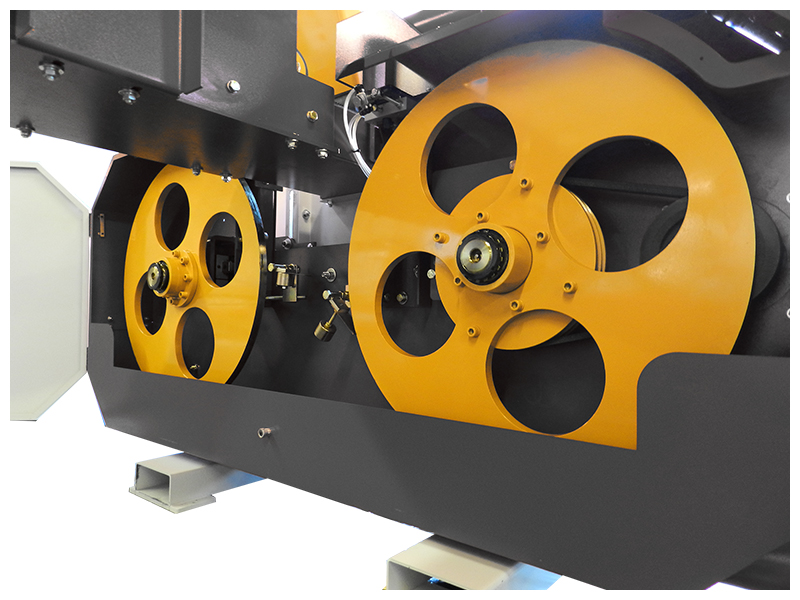

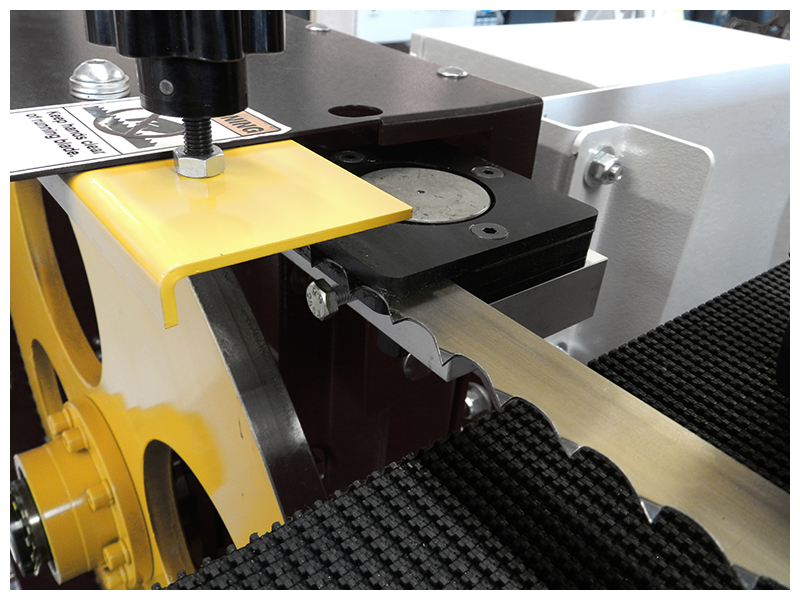

- Solid steel 28” diameter saw wheels capable of running a 1” wide, thin kerf blade for maximum cut accuracy and material yield

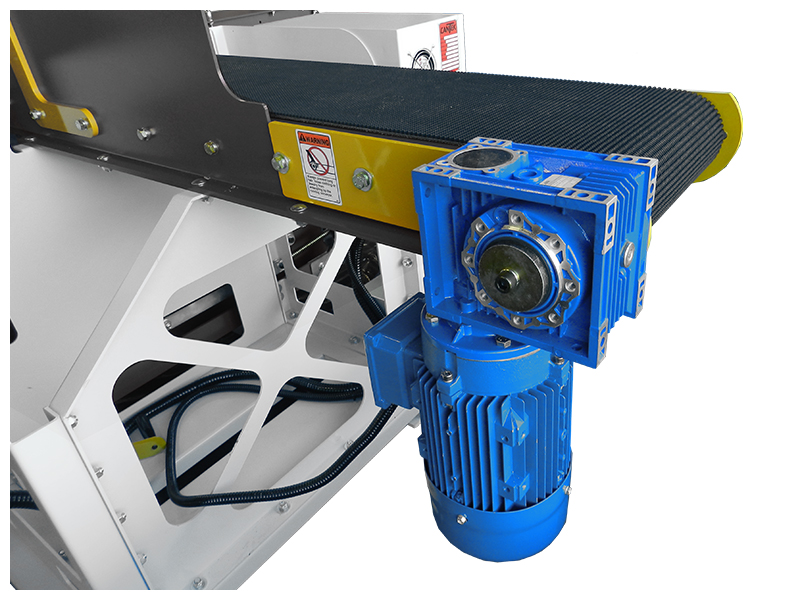

- Variable feed speed by inverter to ensure optimum cut accuracy and blade life

- Simple operation and low price point allowing for the maximum return on your investment

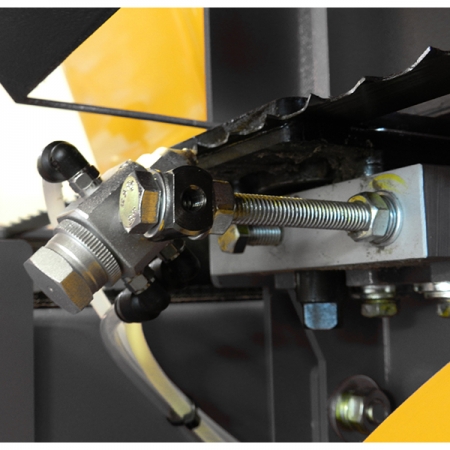

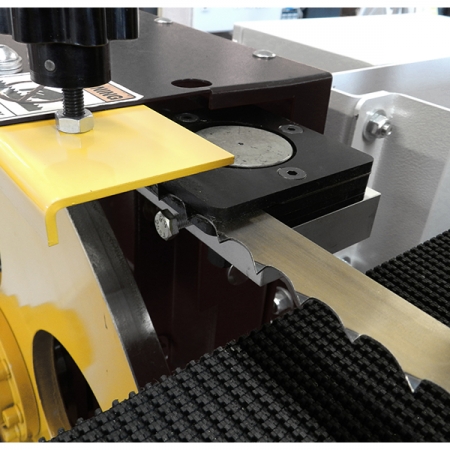

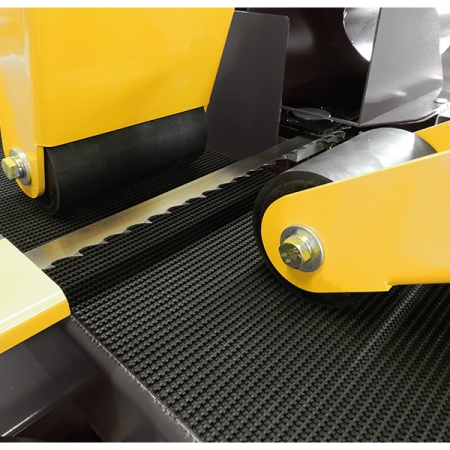

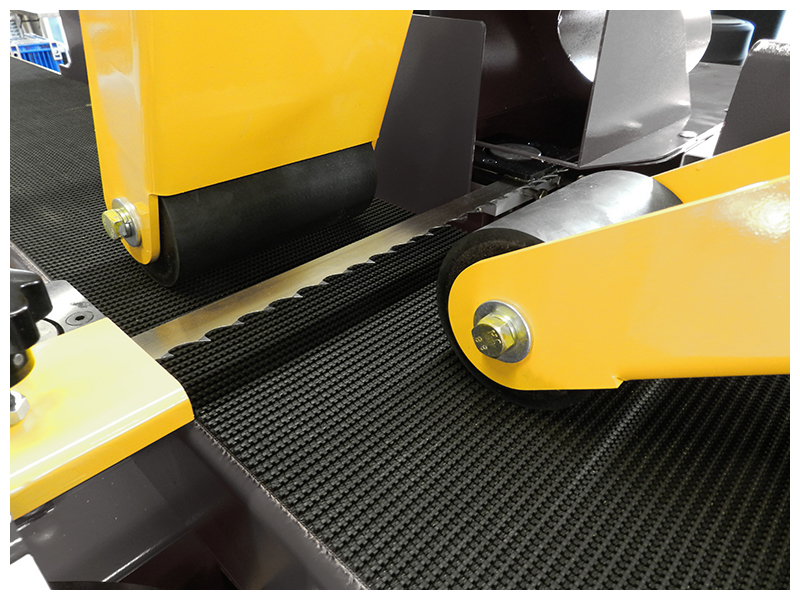

- Adjustable sandwich style guide system ensures the blades run true and cut straight

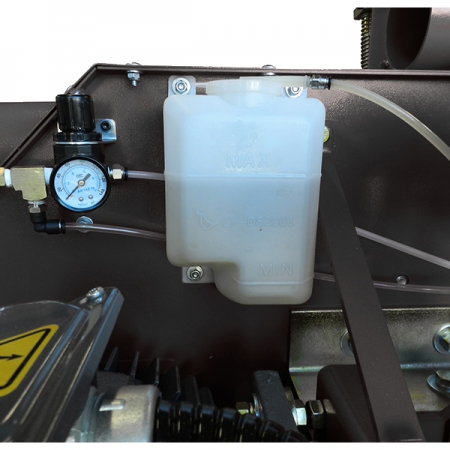

- Blade lubrication system ensure the blade runs cool for an optimum blade life

- Single head horizontal configuration with

- Variable feed speed by inverter from 16 – 82 FPM

- Heavy duty solid steel saw wheels are precision ground and dynamically balanced

- Powerful 20HP saw wheel motor

- Manual saw wheel elevation

- Both saw blade housing elevation screws are linked by a shaft to ensure synchronized movement and precisely level adjustment

- Adjustable sandwich style guide system

- Manual saw blade tension adjustment by handle

- Auto blade lubrication system

- (2) spring loaded hold down rollers ensure material is held firmly on the conveyor belt during material resawing

- Standard electrics are 230/3/60 to UL/CSA Standards (Other voltages available on request)

Dovetails, what’s the big deal?

Machinery SolutionsOnce you open the drawer and see the dovetail design, it elevates your product in the consumer’s eye. But why dovetail machine is right for my operation? When deciding to produce your own drawer boxes, a number of factors come into play when selecting the equipment required.

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.

Kingswood Cabinets. A true commitment to growth.

Case Study, Machinery Solutions, Service and SupportAkhurst is very proud of our involvement in the plant expansion of Kingswood Cabinets of Calgary, Alberta. Kingswood recently relocated to a new state-of-the-art manufacturing facility.