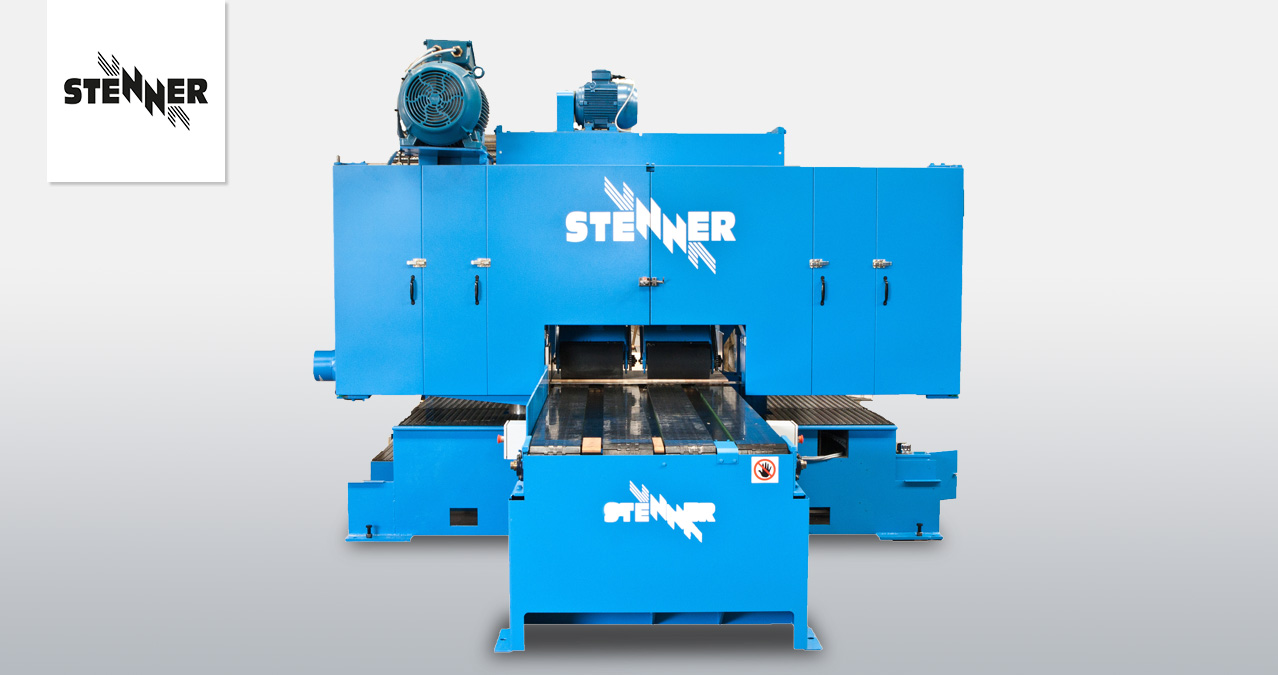

World leading solution for accurate, high yield, volume production.

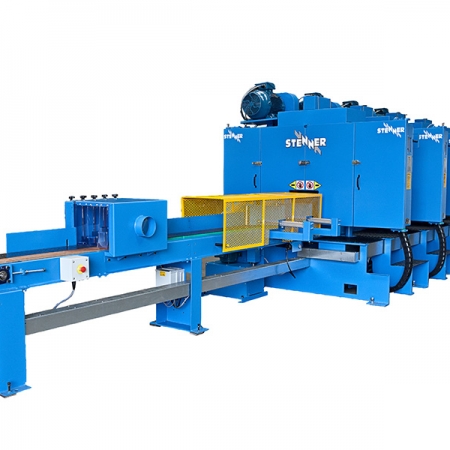

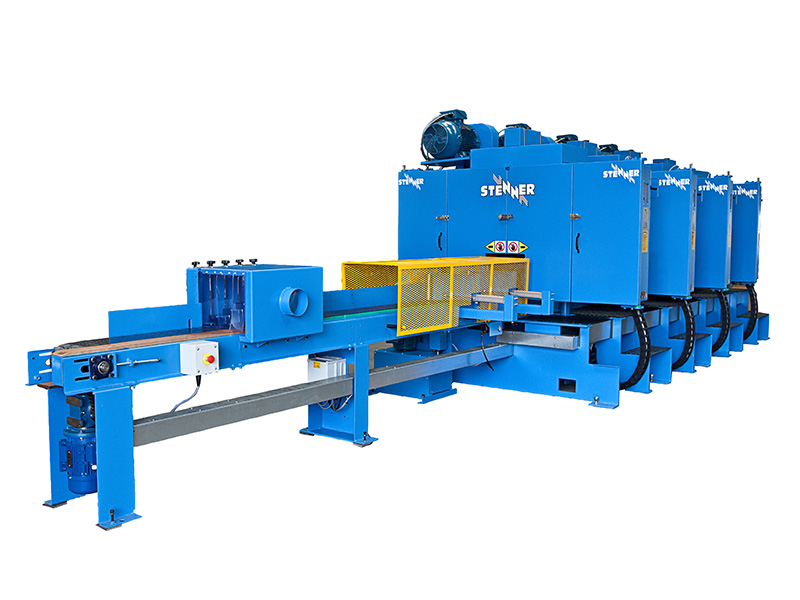

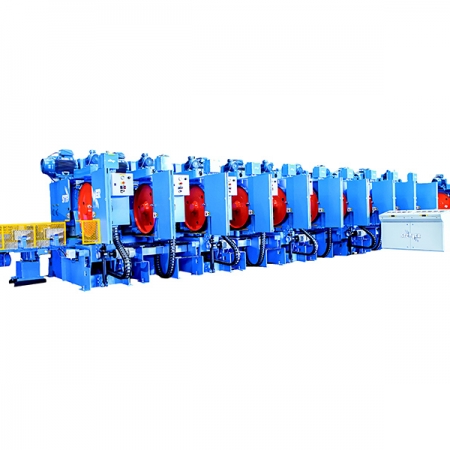

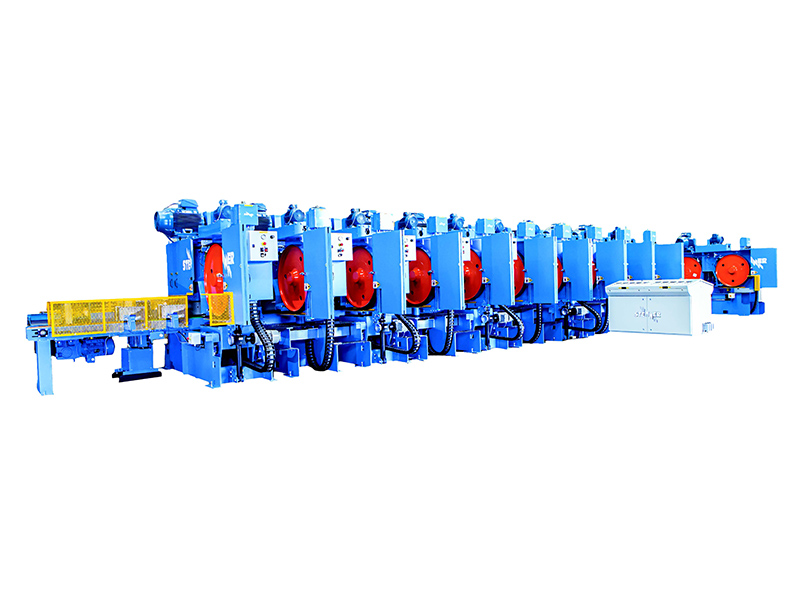

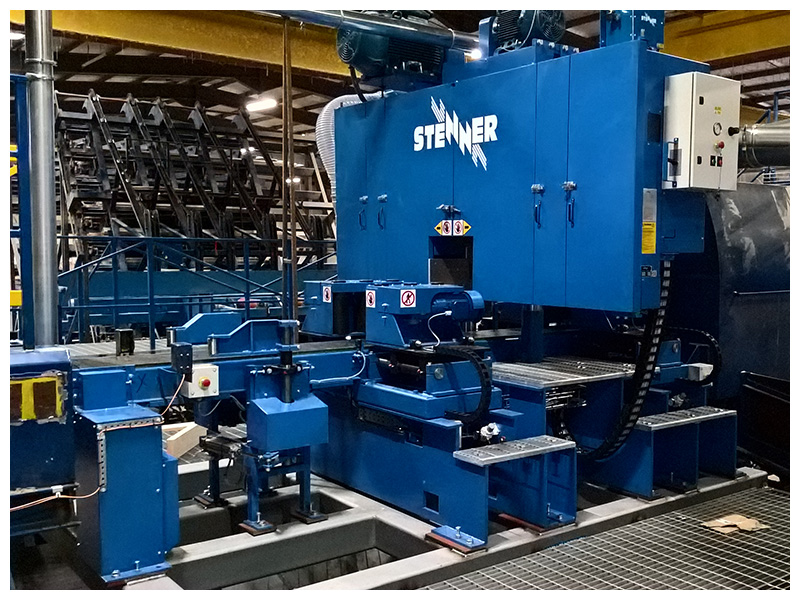

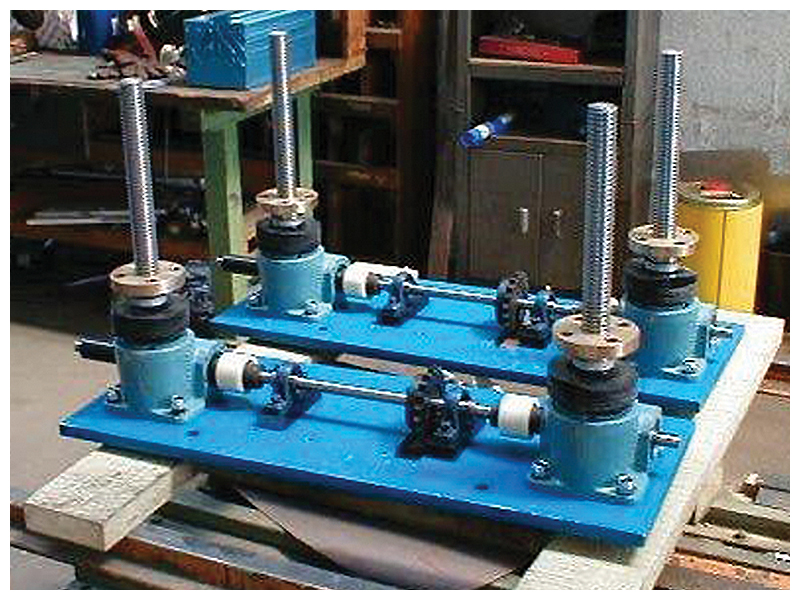

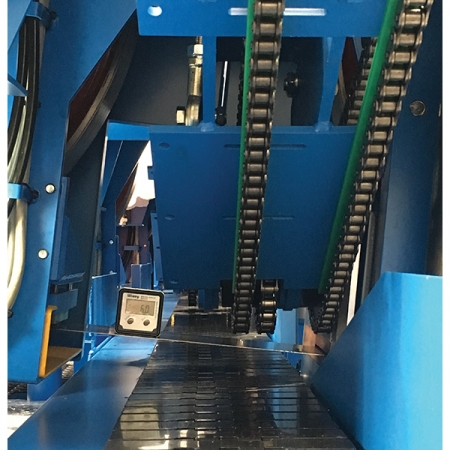

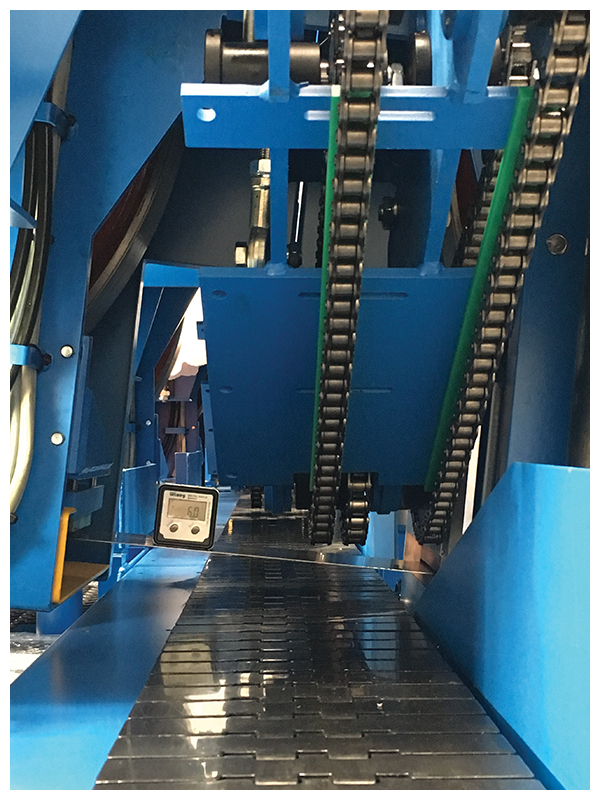

The Stenner MHS Series Multi-Head Horizontal Resaws are ideal for cutting fencing, pallet material, and thin boards, as well as slab recovering and precision resawing of timber. With a thinner kerf and requiring less electrical power than a circular saw multirip, the MHS Series offers productivity and economy; while modular design allows each installation to be tailored to specific requirements, including the number of heads and options such as angle cutting (ie feather-edge boards) and automatic timber return.

Why Stenner MHS Series Multi-Head Horizontal Resaws?

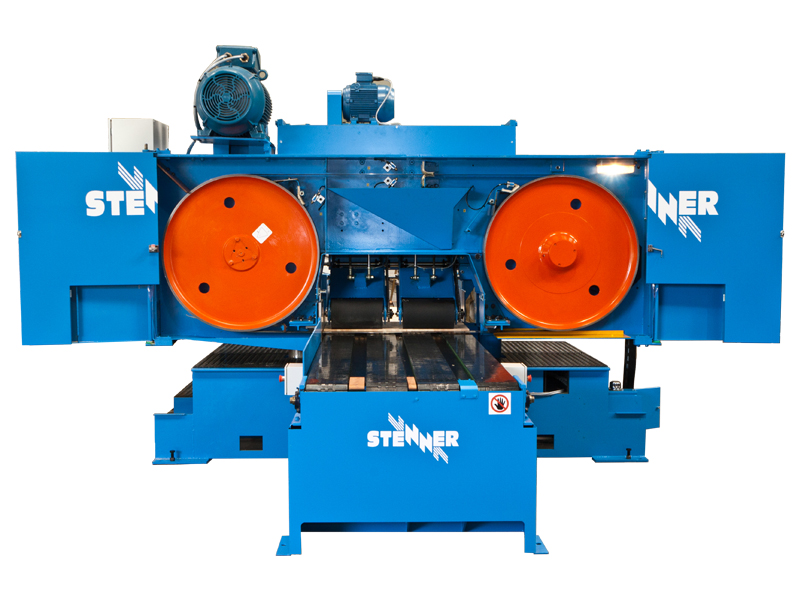

- Track feed speed is steplessly variable and synchronized with the overhead arms, which operate as true radial arms to provide excellent control on different thicknesses of material

- Robust construction

- Modern control systems

- Easy maintenance

- High operational safety

- Stenner’s MHS series multi-head horizontal resaws range has proved popular worldwide with more than 900 saw units installed in diverse applications.

Key performance data

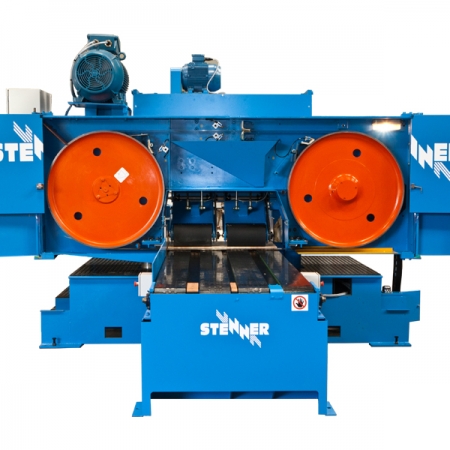

- Available in three models – MHS 9 (pulley diameter 915mm / 36″), MHS 10 (1050mm / 42″) and MHS 12 (1220mm / 48″)

- Maximum timber width (depending on model and configuration) – 305mm or 450mm

- Variable feed speeds – from 7.5-30m/min to 15-60m/min (25 – 100 FPM to 50 – 200 FPM)

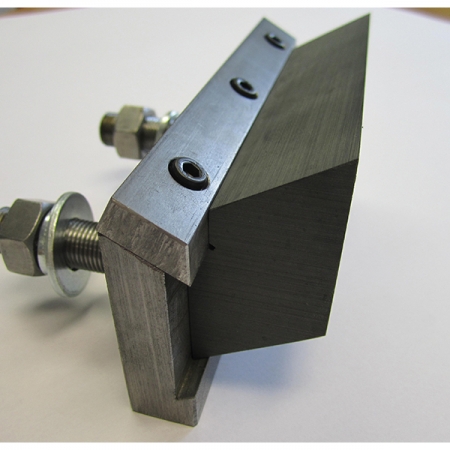

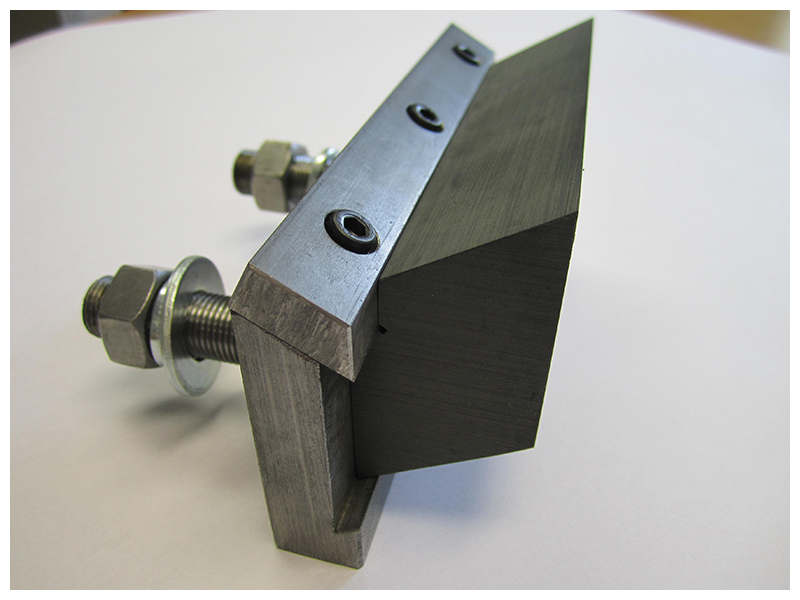

Sawguides

Low friction pressure sawguides of either a disposable or remachinable design provide the excellent blade stability required for accurate cutting.

Sawblade & Pulley cleaning

These machines are fitted with a drip feed cleaning system to lubricate the felt pads. In tandem with scrapers fitted to the pulleys, the felt pads ensure the cleanliness of both the pulleys and the sawblade.

Saw straining

Strain is applied to the sawblade by a pneumatic cylinder, which applies pressure via a linkage when the lever is operated. For safety purposes a low pressure switch is incorporated, which automatically removes power to the main drive motor power (so the machine stops running) if pressure drops to an unsatisfactory level.

Akhurst Machinery Group announces strategic partnership to aid North American housing crisis.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the North American machinery industry, is pleased to announce a strategic partnership with Modular Building Automation (MBA), a Dutch company specializing in machinery for prefabricated homes, modular buildings, and offsite construction solutions. MBA, a joint venture of the renowned companies J.J. Smith in the UK and Ireland and H&M headquartered in the Netherlands, is involved in the design, manufacturing, distribution, and worldwide sales of MBA equipment.

Akhurst Machinery Group announces strategic partnership with Stromab.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the machinery industry, proudly announces a strategic partnership with Stromab SPA, an Italian manufacturer of innovative crosscutting solutions. This collaboration signifies a major commitment by both companies to bring cutting-edge technology and comprehensive solutions to the North American market. Akhurst Machinery Group, the parent company behind the well-known brands of Cantek and Leadermac USA, will leverage Stromab SPA’s expertise in crosscutting solutions to enhance its offerings in North America.

Woodworking Technology Days 2023 is just around the corner.

Corporate, Machinery Solutions, Trade ShowsVisit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.