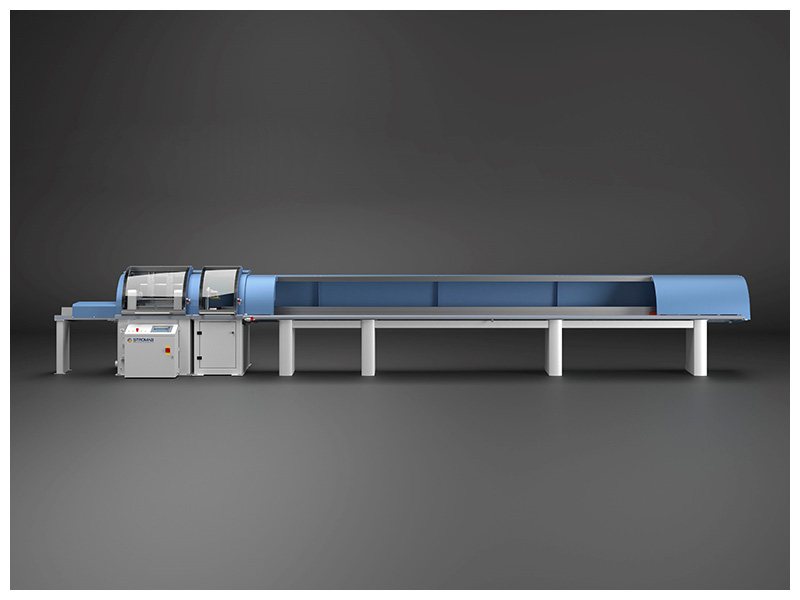

If you need precision straight and angle crosscutting, it’s time to consider CT600 Matrix.

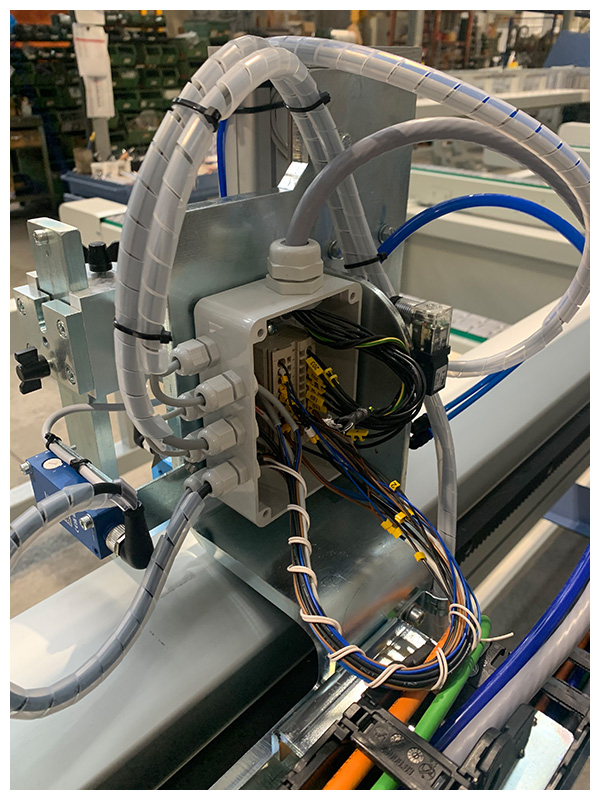

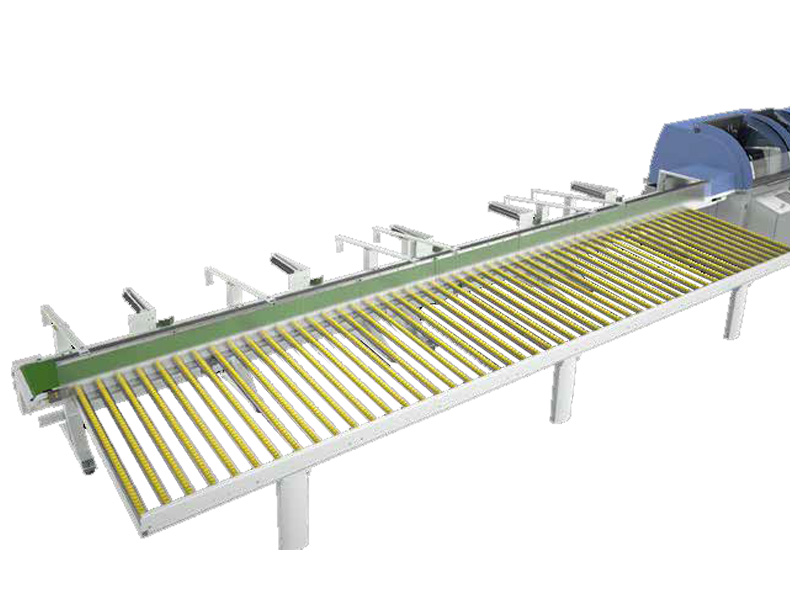

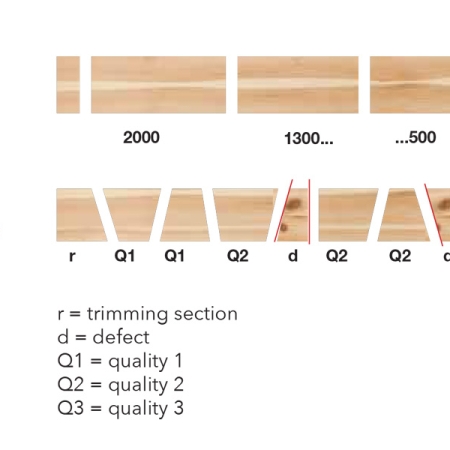

The Stromab CT600 MATRIX stands as a pinnacle of precision cut-off saws, featuring an innovative electronic push feed system with precise axis control with a rotating blade, which has a remarkable range of +/- 70°. This cutting-edge machine seamlessly marries the dependability of a pneumatic angle cut-off saw with an upward-moving blade, an advanced electronic push feed system, and an impeccably accurate rack and pinion guide system. The saw boasts an impressive array of six optimization options: Maximum length, Sequence, Board sequence, Volume, Minimum waste, and Priority. This ensures flexibility and adaptability for various cutting scenarios, maximizing productivity and material utilization. The motor system contains a brushless motor and a planetary reduction unit as well as a precision encoder for unparalleled accuracy. Since its debut, the CT600 MATRIX has surpassed all expectations by reaching unprecedented levels of performance, making it a continuous game-changer in the wood industry

Why Stromab CT600 MATRIX?

- Rotation blade capacity of +/- 70°

- High speed cutting cycle for maximum throughput

- Powerful 10HP main saw motor for effortless capacity cutting

- Precision pusher driven by high speed rack & pinion system

- Equipped with a 12” BECKHOFF CP62XX touch-screen controller, with USB, Ethernet ports, and a WINDOWS operating software system

- Ample storage capacity, accommodating up to 10,000 cutting lists with the ability to load and save machine parameters via USB

- Pneumatic rising of the pusher at the end of the cutting cycle and overhead returning

- Four loading capacity length options: 10’, 13’, 16’, and 20 foot

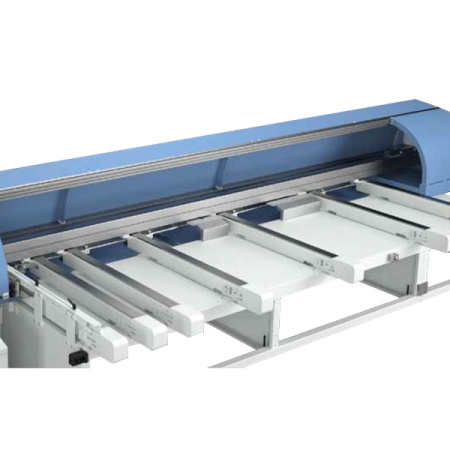

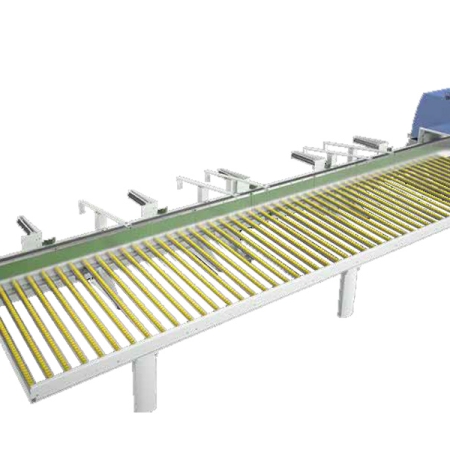

- Various outfeed systems are available from flat tables to automatic sorting kickers

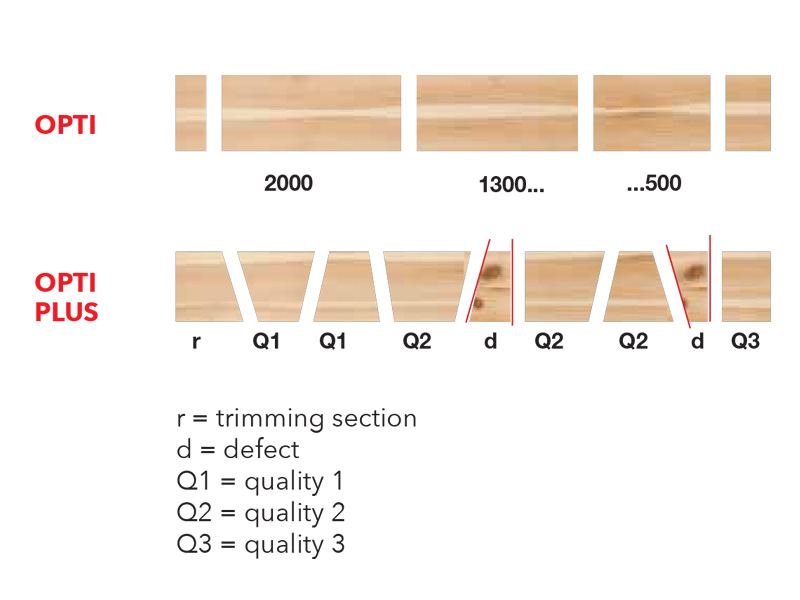

- Two versions available, “OPTI” and “OPTI PLUS”, each offering integrated solutions to cater to diverse needs

- “OPTI”: Automatic Cutting Line with Total Optimization: The standard “OPTI” version provides an automatic measurement function for variable-length materials, whether loaded individually or in bundles, making it a perfect choice for those seeking optimal efficiency

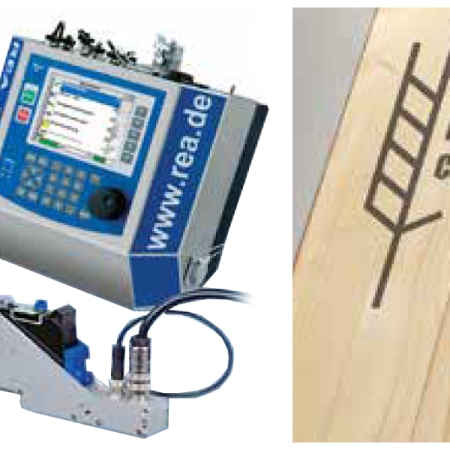

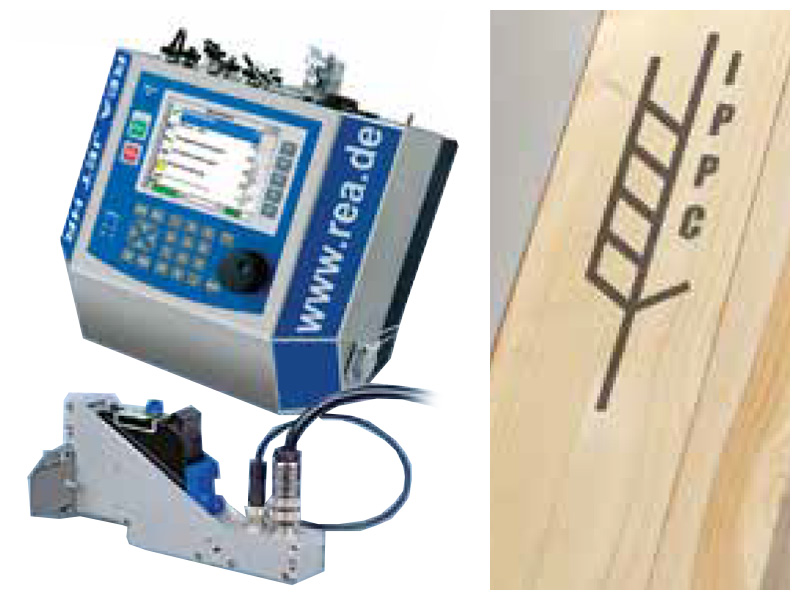

- “OPTI PLUS”: Automatic Cuttign Line with Total Optimization & Defect Cutting: For advanced mark detection ensures complete optimization while eliminating knots and defects. The system marks the material with fluorescent chalk, enhancing precision and quality.

Dovetails, what’s the big deal?

Machinery SolutionsOnce you open the drawer and see the dovetail design, it elevates your product in the consumer’s eye. But why dovetail machine is right for my operation? When deciding to produce your own drawer boxes, a number of factors come into play when selecting the equipment required.

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.

Kingswood Cabinets. A true commitment to growth.

Case Study, Machinery Solutions, Service and SupportAkhurst is very proud of our involvement in the plant expansion of Kingswood Cabinets of Calgary, Alberta. Kingswood recently relocated to a new state-of-the-art manufacturing facility.