Solving the skilled labor shortage with an affordable, advanced machine that anyone can use

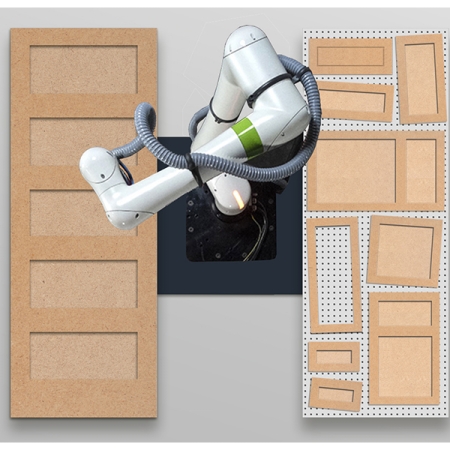

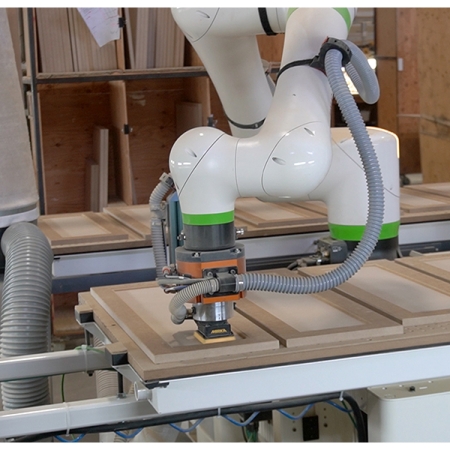

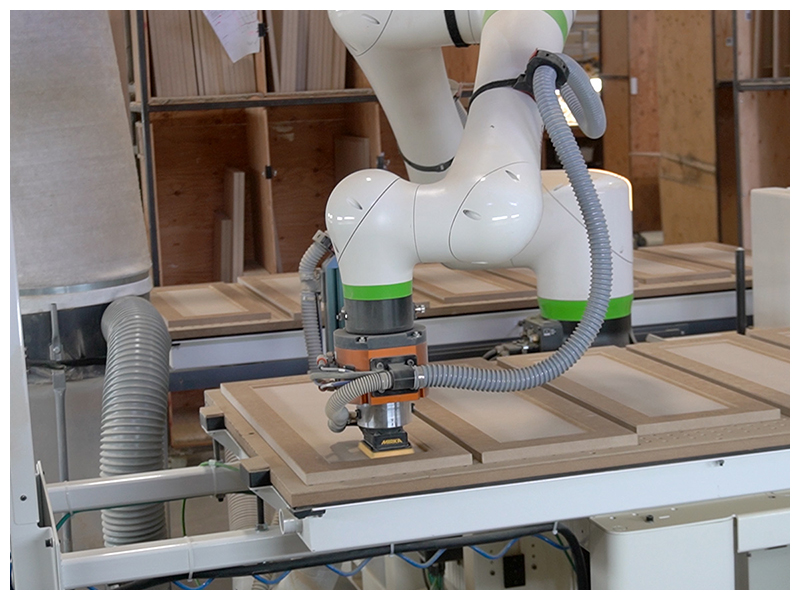

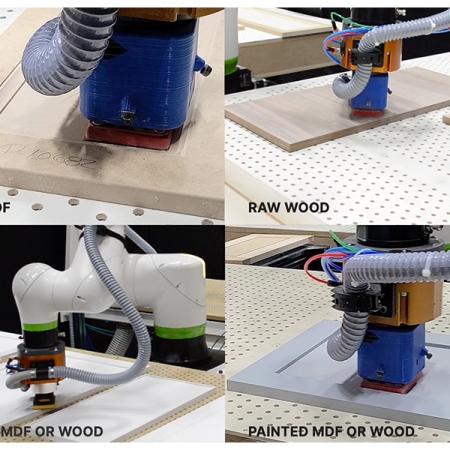

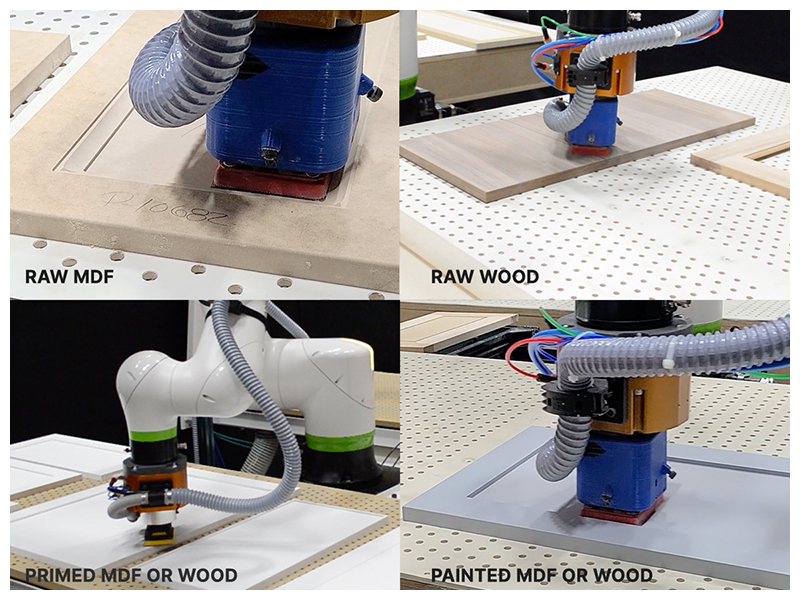

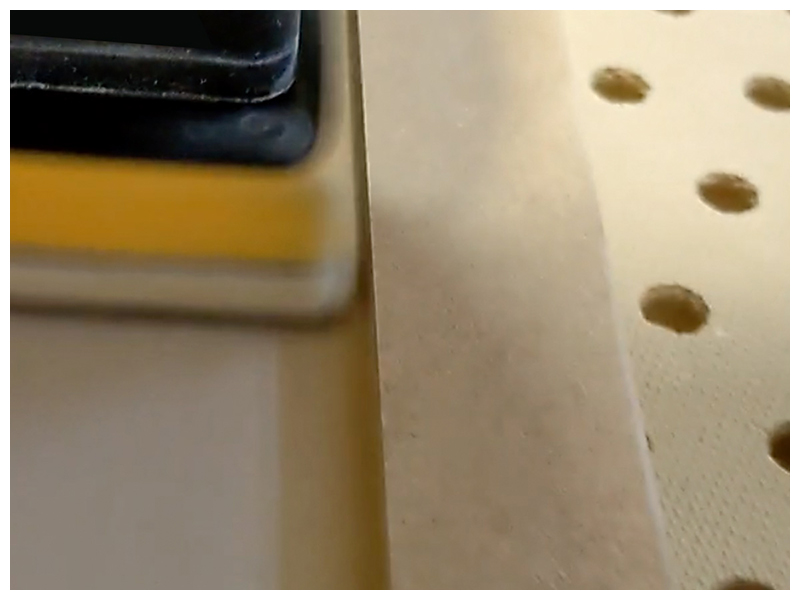

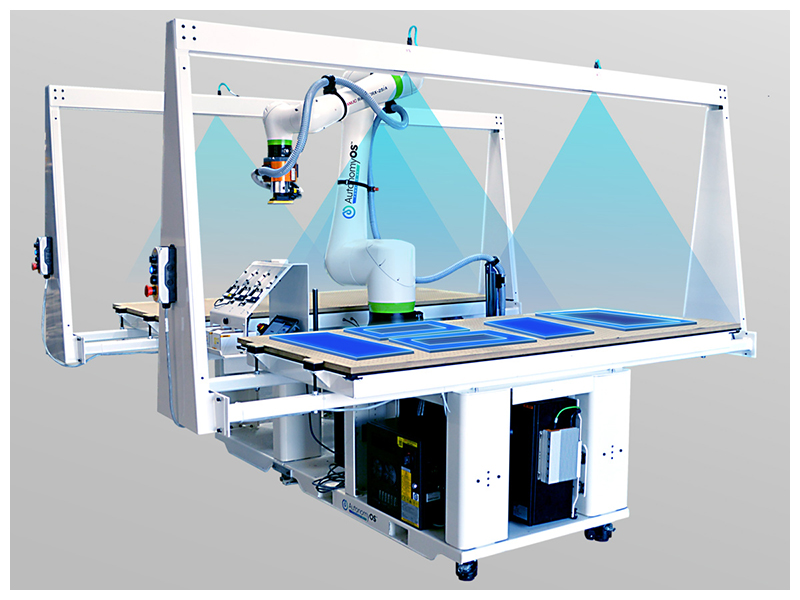

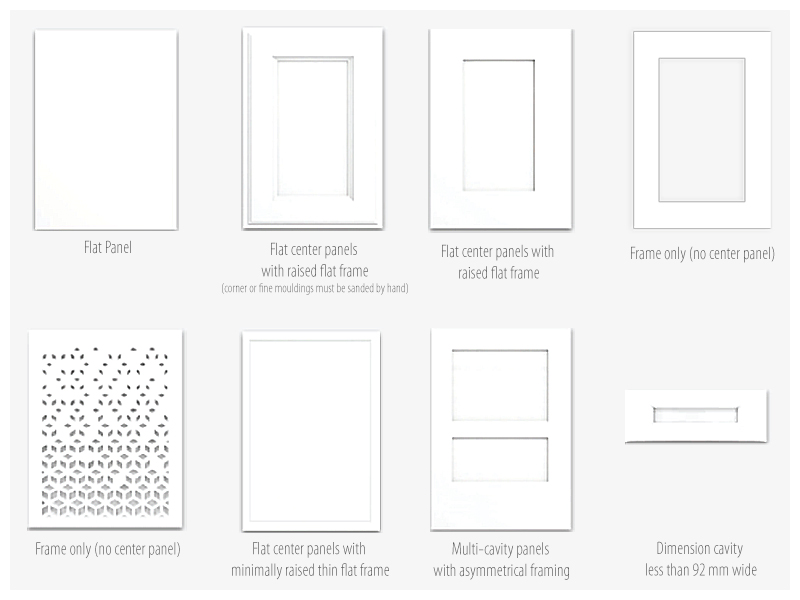

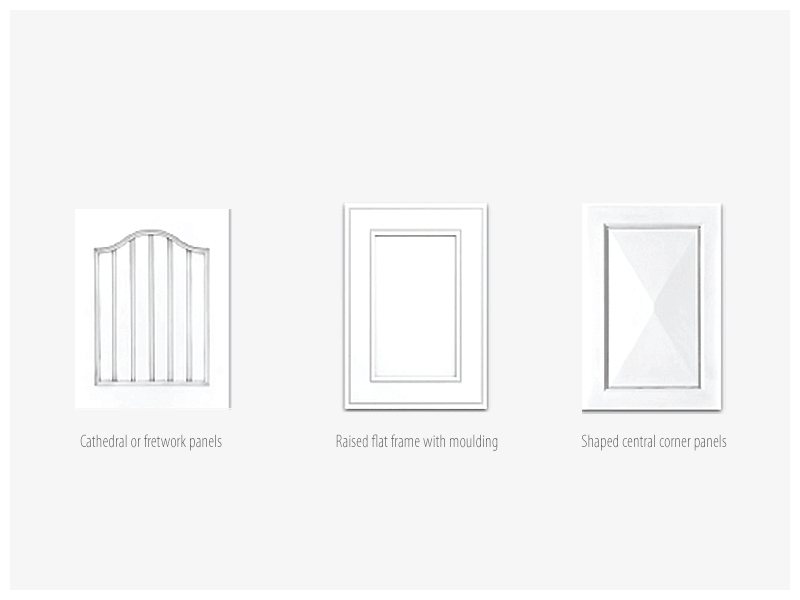

The revolutionary robotic Panel Sanding Assistant from Omnirobotic is designed to solve the issue of finding skilled labour while improving the quality of your sanding operations. Simply place your panels on one of the two tables and the overhead 3D cameras will determine their orientation and type, and scan for both the shape and depth. It will then autonomously sand each door style whether it be a shaker or raised panel type, with a quality second to none. It can sand the center of an MDF shaker door panel and also the face of the door, if required. No need to manually touch up the inside edges or corners. The sanding presets are simply selected by the operator in advance.

With its twin table system the robot can sand on one table while the operator is unloading and loading on the other. This allows for continuous production which greatly improves productivity. A single operator could potentially operate two Panel Sanding Assistants for even greater payback!

Why Omnirobotic Panel Sanding Assistant?

- Proven & tested by kitchen manufacturers

- Dual vacuum table handles demanding workloads of up to 500 panels per shift smoothly and efficiently.

- Six-axis robot arm: Replicates human arm and compensates for variations, ensuring perfect and consistent sanding quality, superior to human results.

- Built-in Neural Engine performs every sanding task autonomously on various panels and frames without fixtures or additional setup.

- Designed to make a difference, it does the heavy lifting to improve the working conditions of the people working alongside it.

- Simple, safe, and robust: Anyone can operate it. No specialized staff or training is required.

- Small footprint and mobile: Make installation easy without stopping your production

- Fast Return on investment, yet a durable machine built to last with minimal maintenance.

Powered with AutonomyOS™, the Panel Sanding Assistant is autonomous. This means you can put any panel anywhere on the table, and it will automatically see, understand the work to be done, and execute it.

- 0.1 mm accuracy gets the desired finish on every panel, every time.

- No fixturing with two Automatic Vacuum Tables that hold any number of panels of any size for higher productivity

- Collaborative Robot Safe to work alongside humans. Empower and retain your employees.

- Laser sensors and advanced motion algorithms plan effective sanding trajectories on every panel size and position

- No Training The Panel Sanding Assistant can be operated by anyone able to use a microwave oven!

- Easy installation within 2 hours. This compact cell fits on any factory floor with its small footprint and large capacity.

- Eight (8) years, Zero (0) maintenance on the robotic arm

- 1 Year Onsite Support*

- 1 Year Remote Support**

* Transport, Traveling & living expenses are cost + 20%

** Requires a permanent internet connection cabled to the equipment

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.