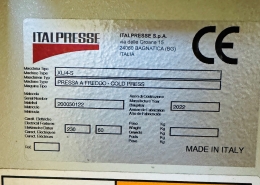

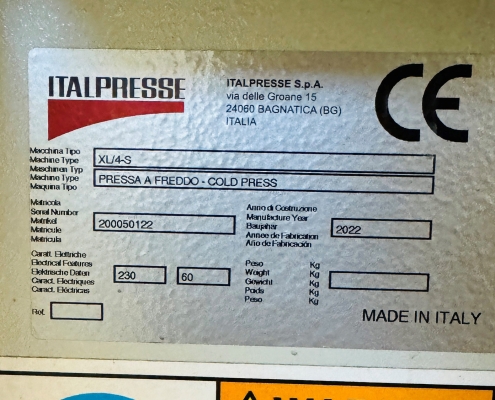

ITALPRESSE

Used Italpresse XL/4-S 25-13 PF Hydraulic Cold Press

Machine Information

Features

PLATENS

- Platen dimensions 2500x1300mm (98’’x 51’’)

- Platens: 2

- Openings: 1

- Opening daylight 400 mm (15.7’’)

- Press platens with high resistance material covered with galvanized steel sheets.

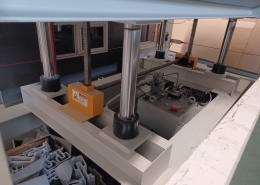

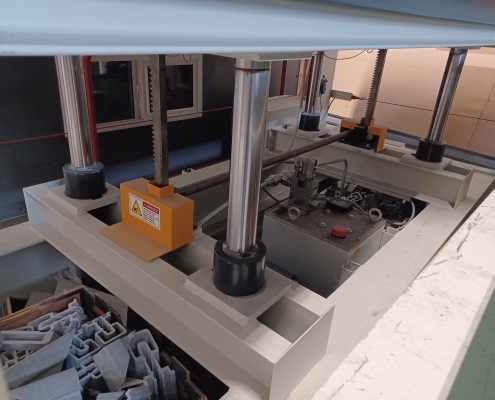

HYDRAULIC CYLINDERS:

- Maximum thrust 50 ton

- Thrust cylinders: 4

- Thrust piston diameter 70 mm (2.75’’)

- Cylinder stroke 400 mm (15.7’’)

- Press cylinders made of special seamless tubes of thick steel.

- Welding done by a robot machine to control all welding parameters.

- CNC machining allows minimum tolerance for precision movement and long life of the seals.

- Pistons are machined out of a steel rod, CNC ground, polished and thickness chromed.

HYDRAULIC SYSTEM

- Compact hydraulic power unit made in Germany (make: HAWE)

- Dual pump for high flow-low pressure and low flow-high pressure steps

- Automatic re-set of hydraulic pressure

- 1 kW Hydraulic power

- Up-stroking movement of bottom platen

CONSTRUCTION DETAILS

- Welded beams press frame, calculated with high structural safety factor

- Frame, moving platen and fixed platen machined on CNC heavy milling machine.

- The moving platen is a fabricated weldment of high thickness steel beams to withstand the pressing tonnage with minimal deflection.

- Self-lubricating guides diagonally placed, for flatness control

- Rack and pinion system assures constant parallelism of the moving platen during closing and opening

OPERATOR INTERFACE

- Key on/off switch

- Light-up pushbutton for emergency resetting (Run)

- “TS 400” Computerized interface to control all press functions:

- 3” colour “TOUCH-SCREEN” monitor for setting, storing, and monitoring all cycle parameters

- Timer for pressing cycle

- Digital temperature control

- Digital pressure control with automatic control of the laminating pressure according to operator entered panel dimensions

- Graphic display of suggested positioning of panels into the press

- Automatic pressure commutation for the panel dimensions

- Fault diagnostic system

- Memory for 200 working program

SAFETY DEVICES

- Two-hand timed press closure push-button switches

- Perimeter e-stop safety cable and switch

- Mechanical platen lock to prevent movement.

- Metal protective covers for potentially dangerous areas

- Adhesive stickers to advise of precautions and danger

- Maintenance and User’s manual

Options Included

Machine Details