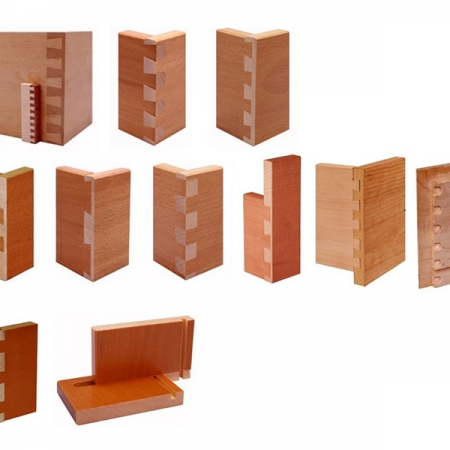

High-quality dovetail joints with maximum flexibility.

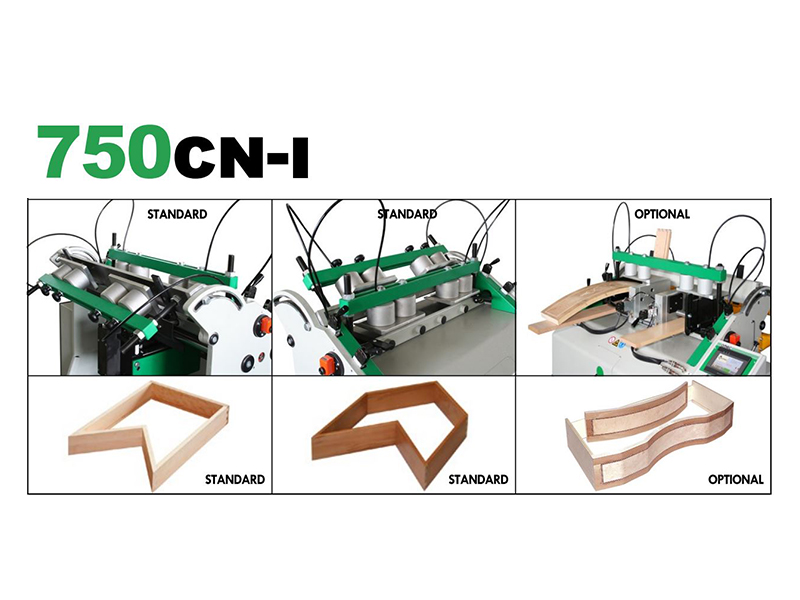

The OMEC 750CN-C is a two-axis automatic dovetailer with touchscreen computer numerical control, offering a wide range of dovetail joints with optimized cycle times. The operator is prompted to enter the width of the drawer side to be machined, and the dovetail pattern desired. With a variable pitch, you are no longer limited to working on fixed centers allowing for more flexibility for your specific needs. Blowout is minimized as the speed of the cut can be adjusted to accommodate the type of material and the joint being produced. The touch screen allows the operator to store programs for quick recall, so results are repeatable time after time. It is now equipped with an enclosure over the milling unit for reduced noise pollution and improved dust collection. The OMEC 750CN-C is an excellent dovetail machine for the high-end dovetail drawer maker who wants to offer premium drawers and appreciates the flexibility a CNC machine offers.

Why Omec 750CN-C CNC Dovetailer?

- User-friendly touchscreen interface with 7” graphical display

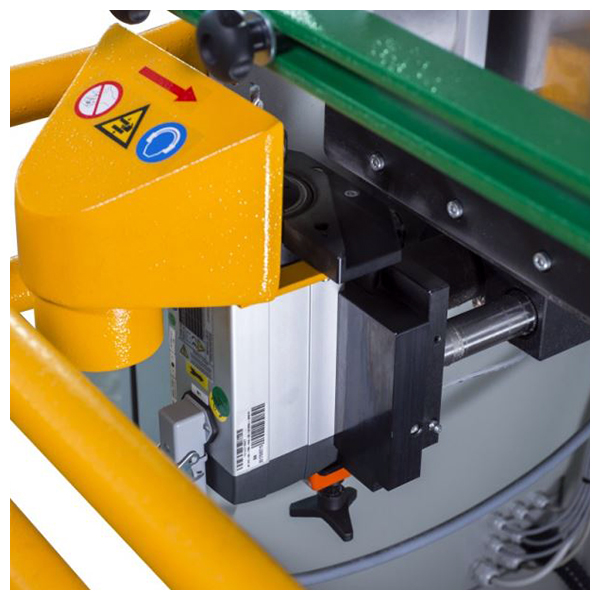

- Full enclosure over the milling unit for improved dust collection and reduced noise pollution

- Production capacity of up to 60 dovetail drawer boxes per hour

- Optimized cutting cycle according to the drawer height being machined

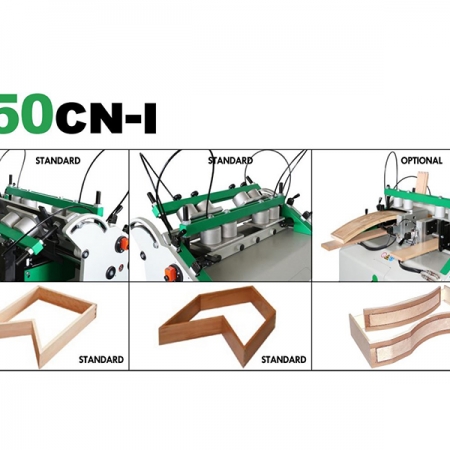

- A wide range of dovetail programs come standard with the machine

- Fixed and variable dovetail pitch programs

- Adjustable cutting speed for optimum finishing results

Capable of selecting:

- Pitch of indents

- Number of indents

- Depth of indents

- Dimensions of the pieces

- Cutting speed and tool feeding

- Compensation of the tool radius variation

- Storage of up to 600 custom programs

Dovetails, what’s the big deal?

Machinery SolutionsOnce you open the drawer and see the dovetail design, it elevates your product in the consumer’s eye. But why dovetail machine is right for my operation? When deciding to produce your own drawer boxes, a number of factors come into play when selecting the equipment required.

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.

Kingswood Cabinets. A true commitment to growth.

Case Study, Machinery Solutions, Service and SupportAkhurst is very proud of our involvement in the plant expansion of Kingswood Cabinets of Calgary, Alberta. Kingswood recently relocated to a new state-of-the-art manufacturing facility.