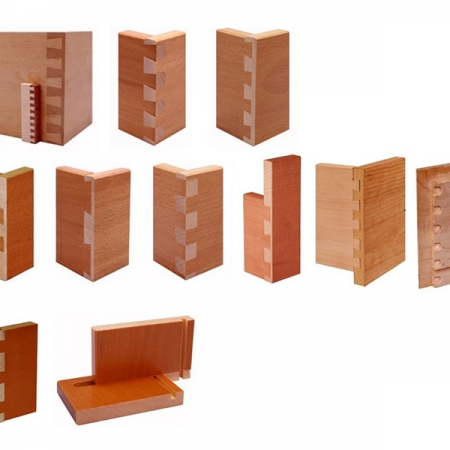

High-quality dovetail joints with maximum flexibility.

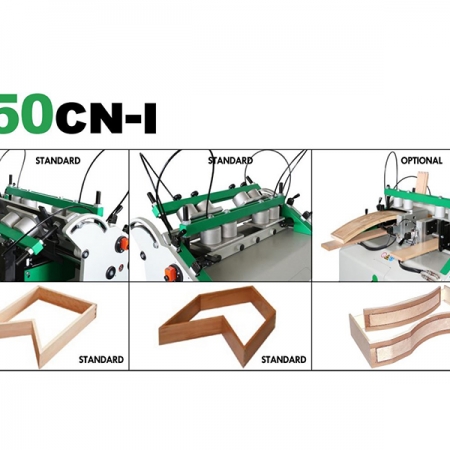

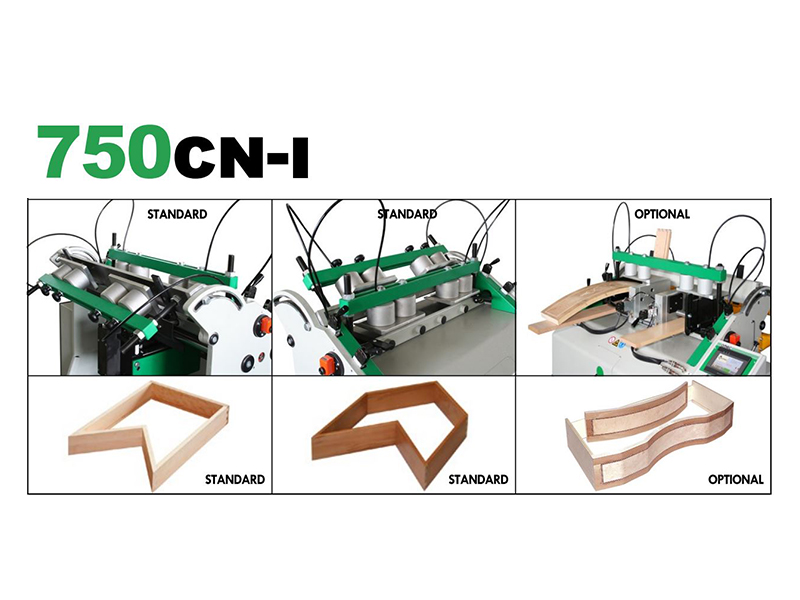

The OMEC 750CN-C is a two-axis automatic dovetailer with touchscreen computer numerical control, offering a wide range of dovetail joints with optimized cycle times. The operator is prompted to enter the width of the drawer side to be machined, and the dovetail pattern desired. With a variable pitch, you are no longer limited to working on fixed centers allowing for more flexibility for your specific needs. Blowout is minimized as the speed of the cut can be adjusted to accommodate the type of material and the joint being produced. The touch screen allows the operator to store programs for quick recall, so results are repeatable time after time. It is now equipped with an enclosure over the milling unit for reduced noise pollution and improved dust collection. The OMEC 750CN-C is an excellent dovetail machine for the high-end dovetail drawer maker who wants to offer premium drawers and appreciates the flexibility a CNC machine offers.

Why Omec 750CN-C CNC Dovetailer?

- User-friendly touchscreen interface with 7” graphical display

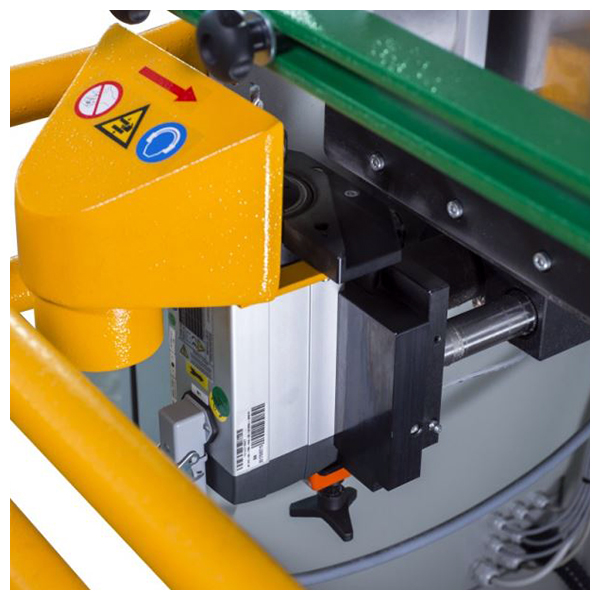

- Full enclosure over the milling unit for improved dust collection and reduced noise pollution

- Production capacity of up to 60 dovetail drawer boxes per hour

- Optimized cutting cycle according to the drawer height being machined

- A wide range of dovetail programs come standard with the machine

- Fixed and variable dovetail pitch programs

- Adjustable cutting speed for optimum finishing results

Capable of selecting:

- Pitch of indents

- Number of indents

- Depth of indents

- Dimensions of the pieces

- Cutting speed and tool feeding

- Compensation of the tool radius variation

- Storage of up to 600 custom programs

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.