Laser Cutting, Thermal Drilling, and Tapping for a single piece Molding.

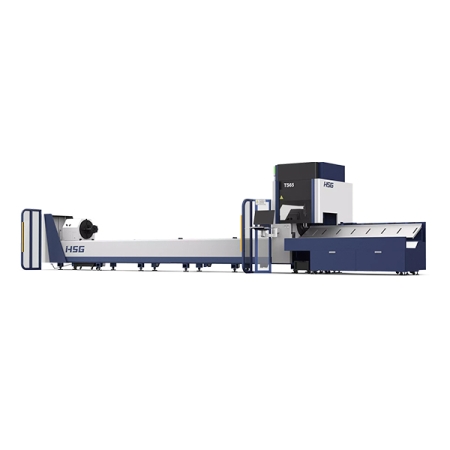

The HSG Laser TPSD Series is their flagship serious compound tube fiber laser cutting machine with drilling and tapping. It integrates the functions of laser cutting, thermal drilling, and tapping to achieve a single-piece molding. It can also achieve exquisite 45° angle bevel cutting, reducing processing steps, saving labor, greatly reducing processing time and improving production efficiency. Equipped with SPEED+ high-speed cutting technology, the maximum acceleration can reach 1.2G, and the chuck speed can reach 120r/min, greatly improving the cutting efficiency of dense small graphics.

Why the HSG TPSD Series Compound Tube Fiber Laser Cutting Machine?

- X9500 tube cutting bus system

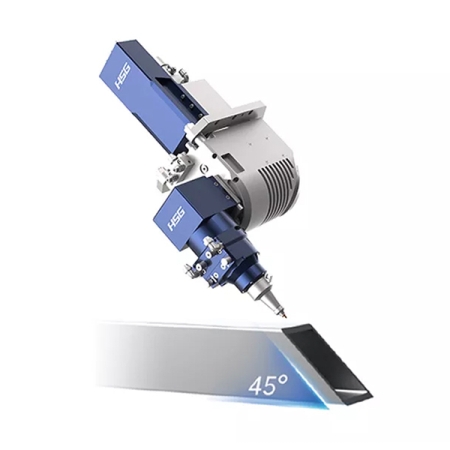

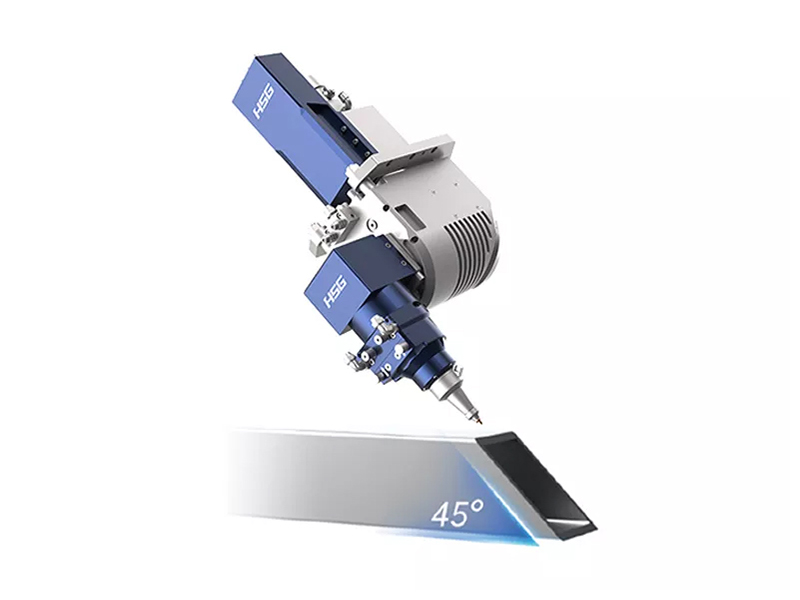

- Beveling processing for shaping at once

- Intelligent and wireless digital chucks

- SPEED+multi-axis interpolation high power cutting technology

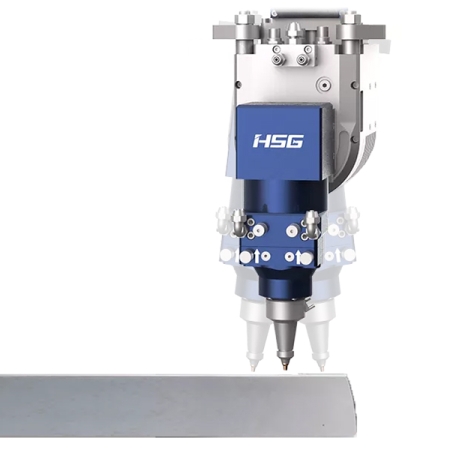

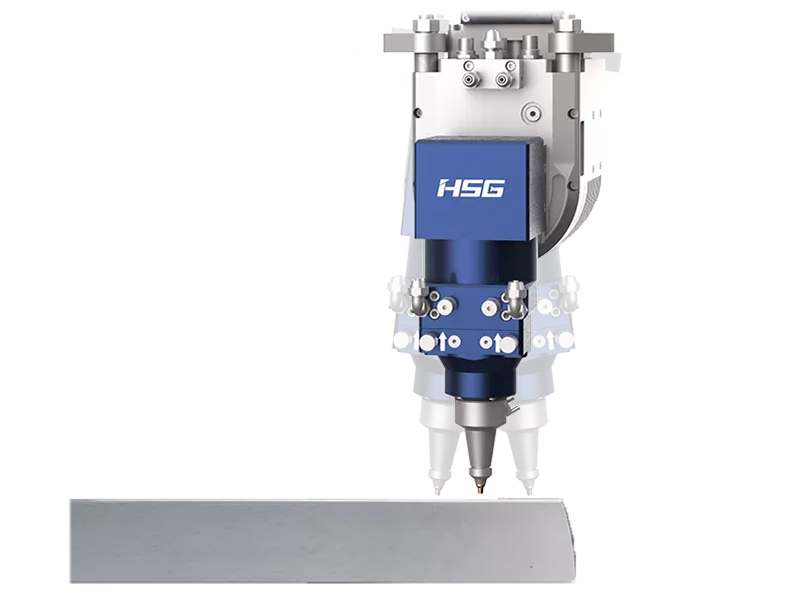

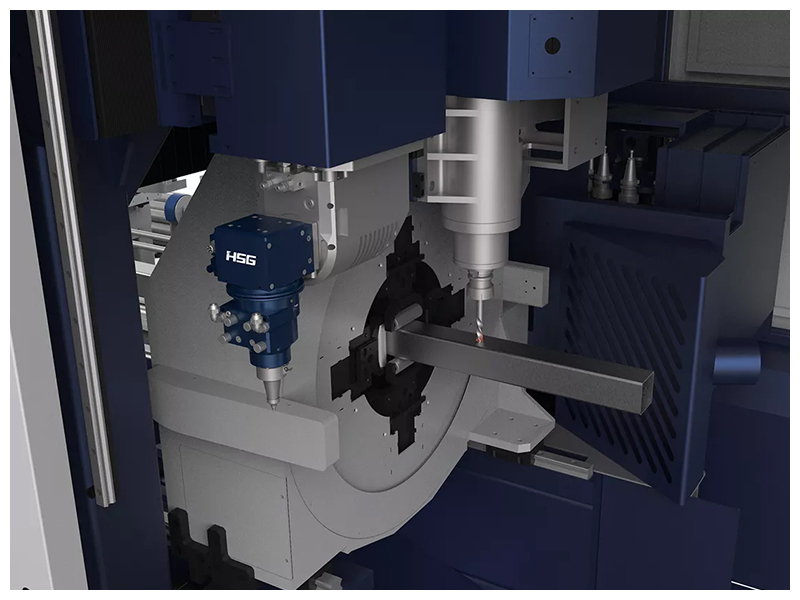

Efficient Production: Cutting + Drilling + Tapping

Integrated laser cutting, hot melt drilling and tapping, for molding at once to reduce processing processes, save labor, greatly shorten processing time and improve production efficiency

SPEED+ High-speed Tube Cutting Technology

Using SPEED+ high-speed cutting technology to improve the cutting efficiency of dense small graphics for high-speed tube cutting.

- Chuck Rotation Speed: 120r/min

- Chuck Linkage Speed: 120m/min

Intelligent Digital Chuck

The chuck can detect the clamping status and the tube size data to achieve self-adjustment of clamping force.

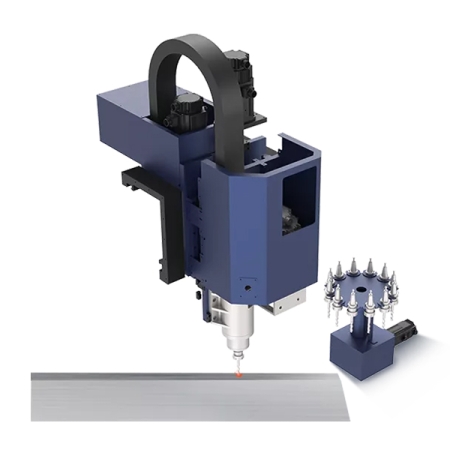

Beveling Processing

HSG-LA4 tube beveling tube cutting head to achieve 0-45°beveling cutting.

Multiple Apertures Hot Melting -Drilling-Tapping Technique

Self-equipped with tool database to achieve automatic knife shifting.