High Acceleration, Speed, Precision.

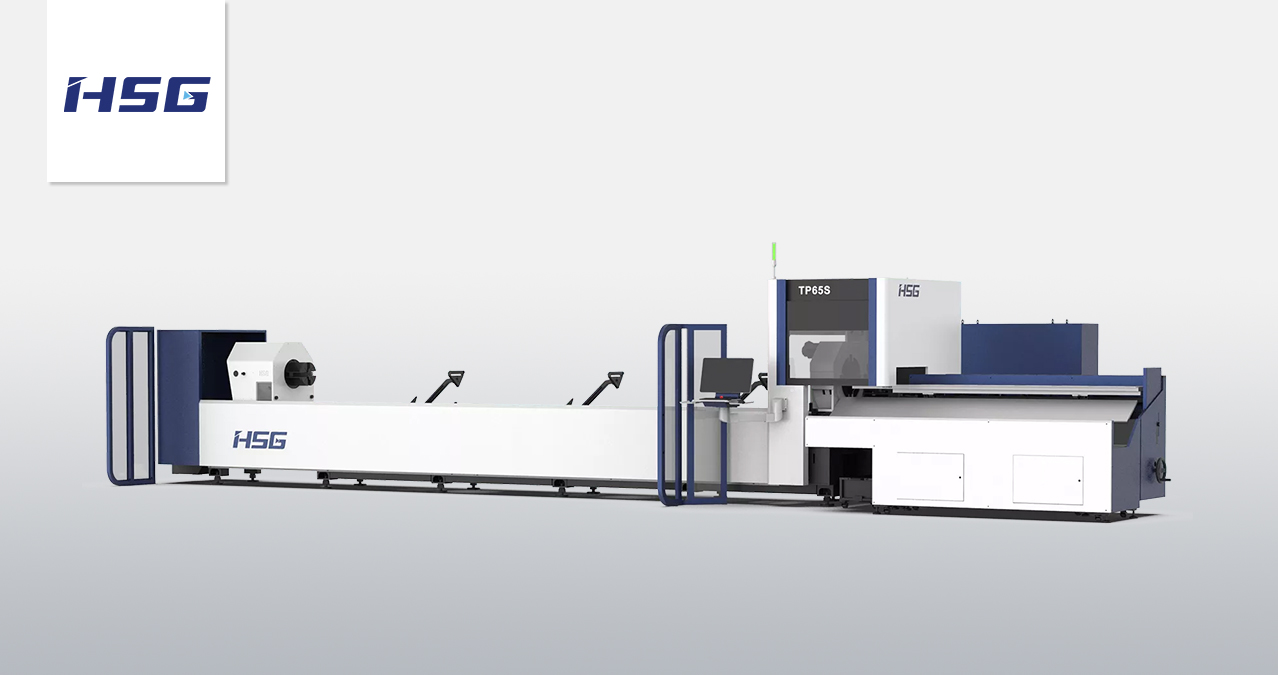

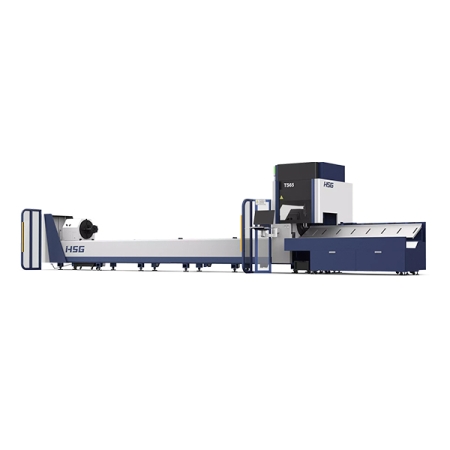

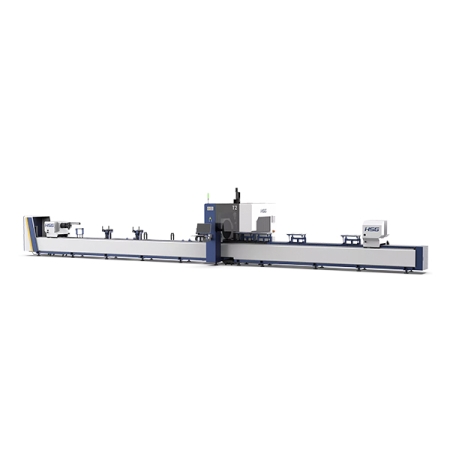

HSG Laser’s TPS series is a professional laser machine for cutting pipe profiles. The TPS is the leading tube laser cutting machine thanks to its high acceleration movement speed and precision. It comes equipped with bevel cutting up to 45° to optimize fit and facilitate welding. TPS can cut most pipe profiles in addition to round and rectangular, for example L, H, U profiles.

Expand your capabilities with the superior TPS pipe laser cutting machine with five-axis cutting. The TPS Series machines’ core technology is designed to efficiently cut heavy tubes and a wide range of pipes.

Why the HSG TPS Bevel Tube Laser Cutting Machine?

- High speed and intelligent for better processing

- X9500 Bus-based tube cutting control

- Intelligent digital chucks

- Powerful functions so you’ll never spend time worrying

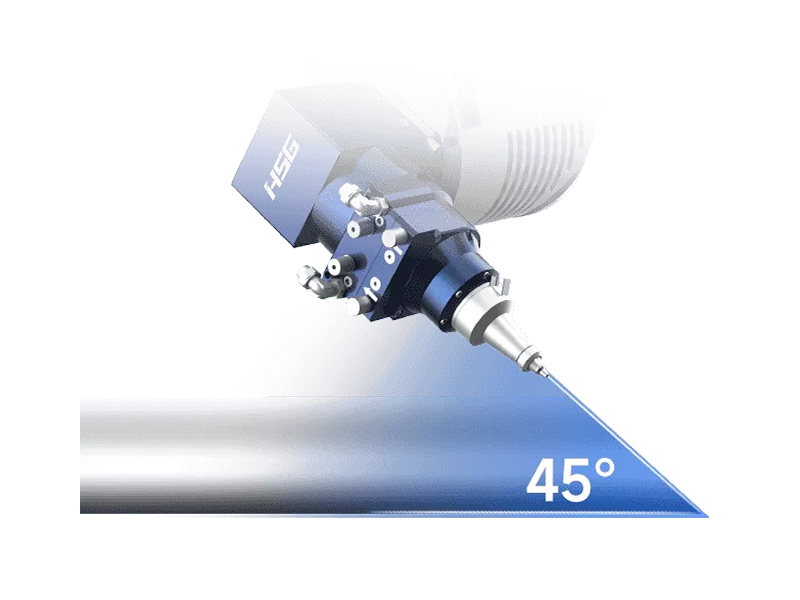

- LA4 bevel cutting head

- Tube splicing technology

LA4 Beveling Cutting Head

LA4 beveling cutting head can achieve 0-45°beveling tube processing to bring convenience for following welding technology and reduce costs.

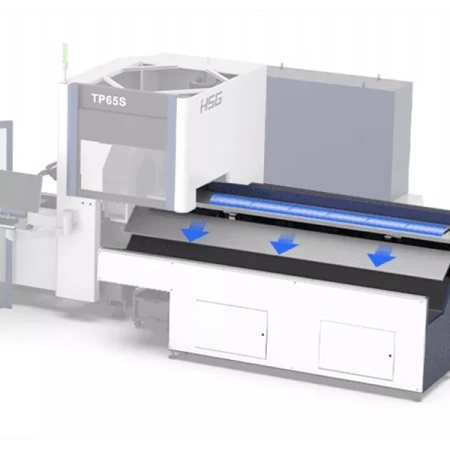

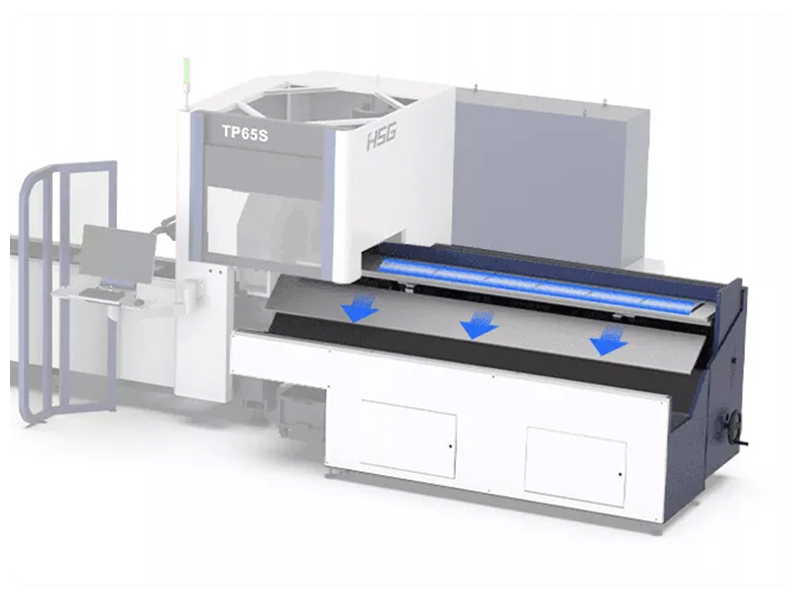

Dust Removal

There are air hose on front chuck and high-power exhaust fans that work together to cut down smoke pollution and keep operators healthy.

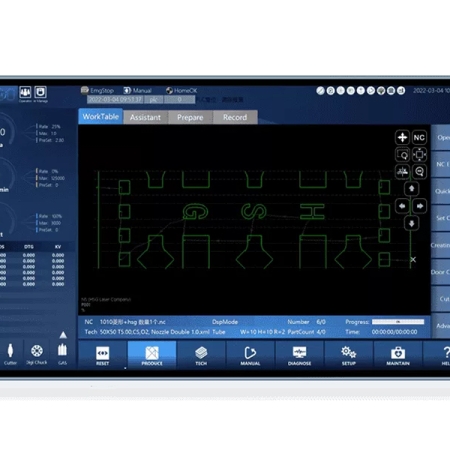

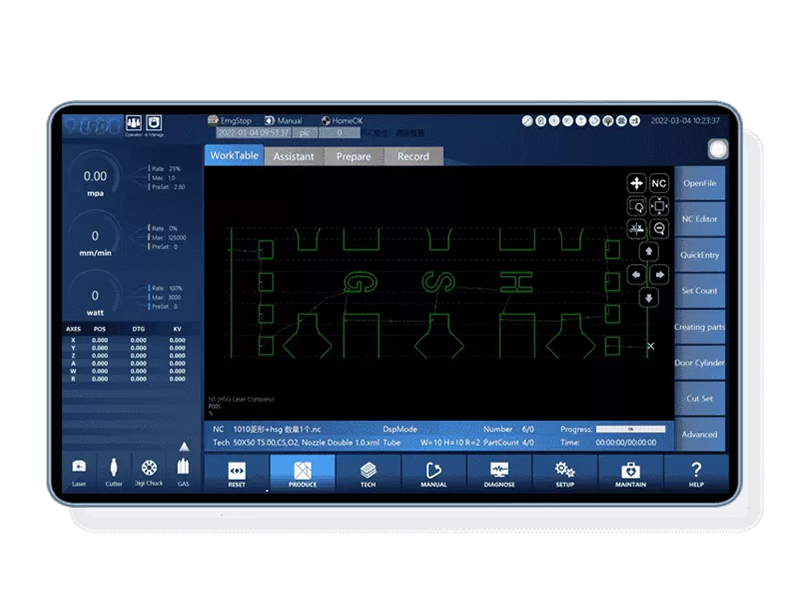

HSG-X Bus Control System

HSG-X control system is bus-based and developed by HSG Laser. With intelligent and easy-to-operate service, it can offer users effective solutions to address problems of difficult operation, low efficiency and high costs.

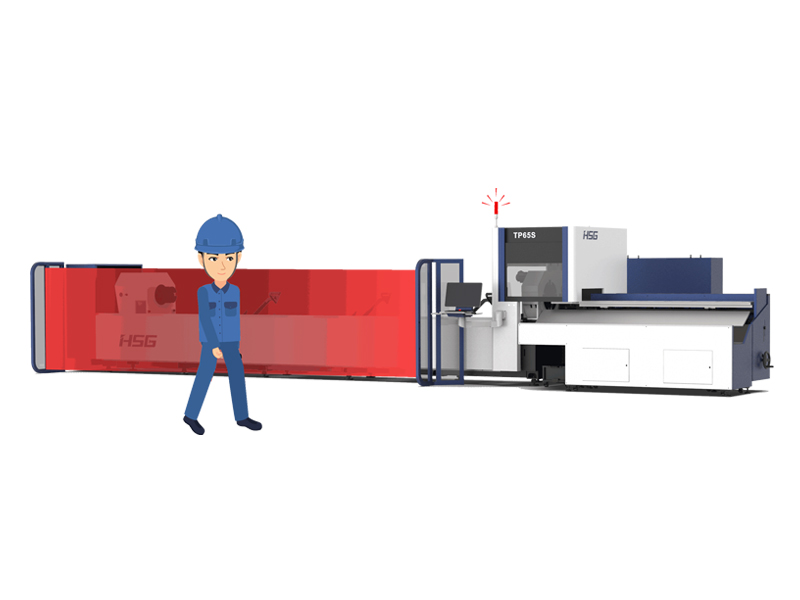

Safety Light Curtain

It will give alarm if any intruder is detected when chucks are working at high speed, so as to prevent any possible collision with human body and protect both workers and the machine well.

Automatic Unloading Device

Follow-up turning plate and concave wheel as unloading device are fit for unloading large tubes.

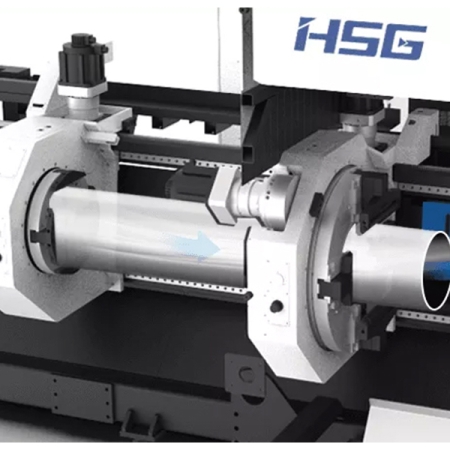

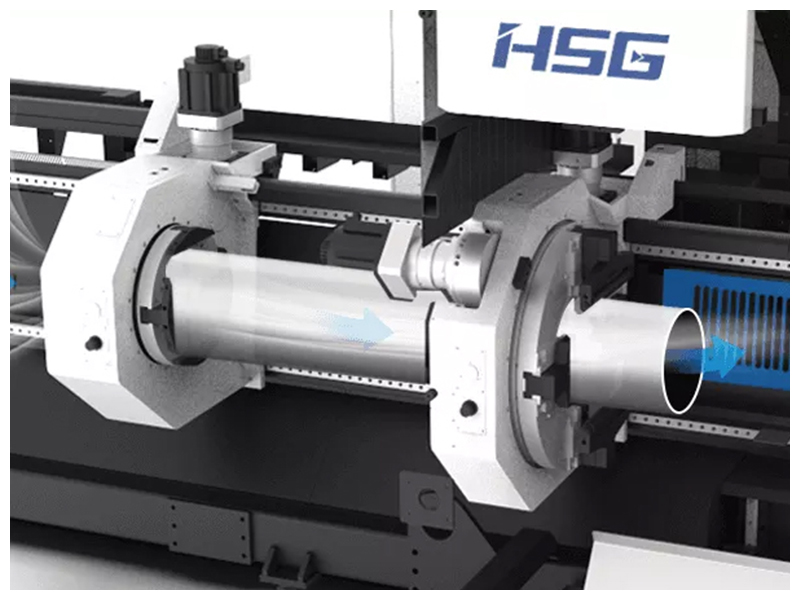

Digital Controlling Pneumatic Chucks

- With wireless digital feedback, chucks combine with system to form closed-loop controlling

- High clamping speed, accuracy and working efficiency , low threshold pressure

- Wireless monitoring of chucks, alarm for empty chucks and high security for no collision between chucks and work-pieces

- Pressure adjustments depending on different tube diameters and thicknesses

- Intelligent chucks in full track without artificial adjustments and the load-bearing can achieve 200kg.