Heavy Duty, Automated, Intelligent.

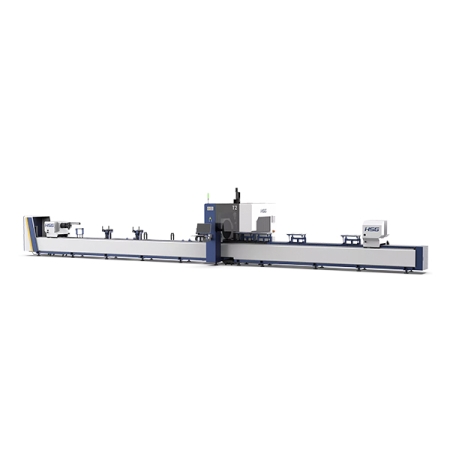

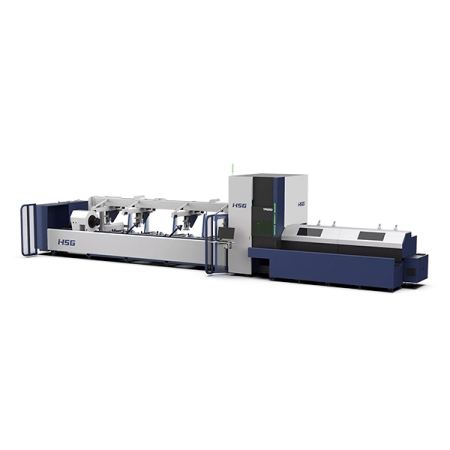

The HSG Laser TX Series tube fiber laser cutting machines adopts lateral machine bed design to lower the tube’s center of gravity, thus ensuring a more stable processing of heavy duty tubes and facilitating automated loading and unloading of tubes. The 3+1 twin chucks structure can achieve the complete tube cutting to reduce tailing waste and help users save material costs. For satisfying customer needs of long tube processing, we provide customized solutions to achieve maximized tube processing length of 15 meters. HSG laser cutting technology can effectively process the screen liner, ensure that the cutting seam is regular, high finish and intelligent system operation is easy to operate and save time.

Why the HSG TX Series Heavy Duty Tube Fiber Laser Cutting Machine?

- High speed and intelligent for better processing

- X9800 bus-based tube cutting control system

- 3+1 Twin chuck clamping cutting technique

- Powerful functions so you’ll never spend time worrying again

- Follow-up supporting plate as unloading device database (optional)

- Tube splicing technology

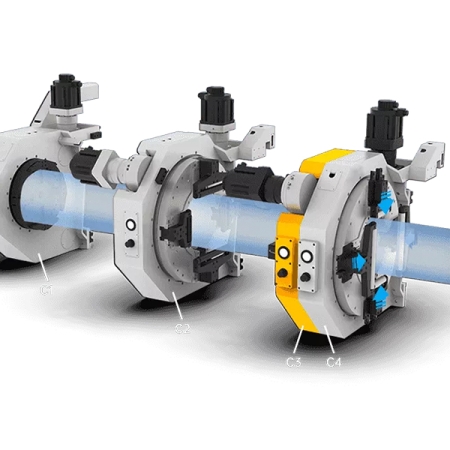

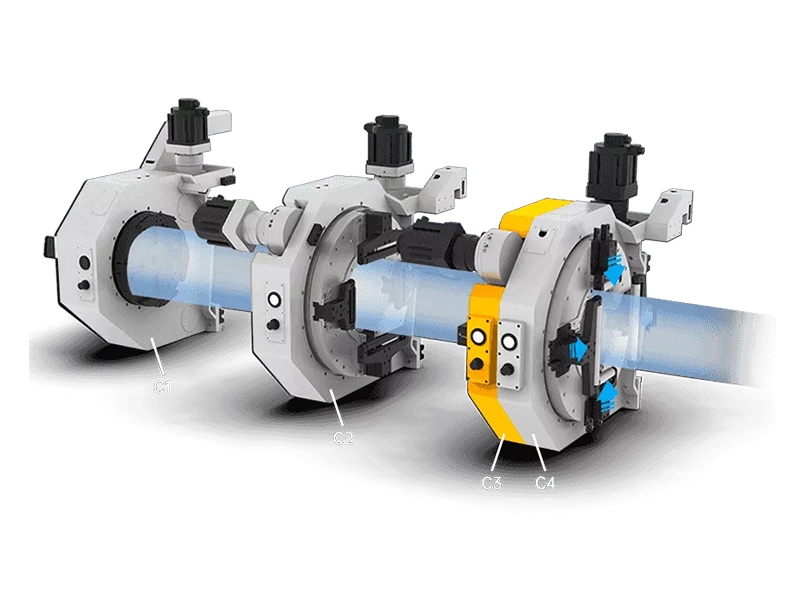

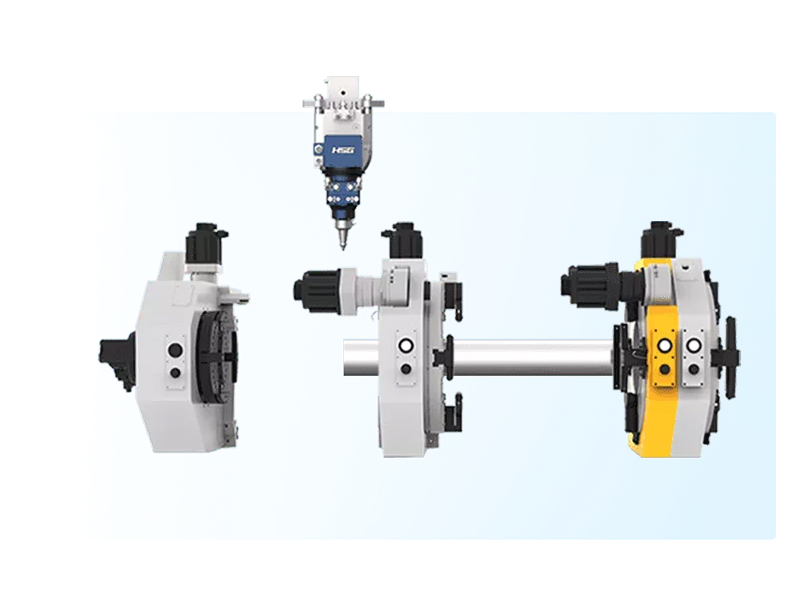

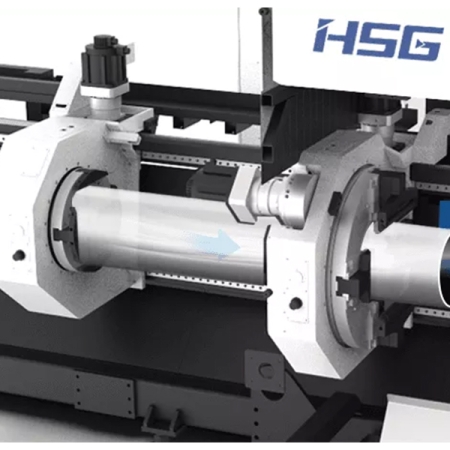

3+1 Twin-chucks Clamping

The chucks are developed by HSG Laser and have got Chinese patent for invention. They not only address prevailing problems faced by two, three and other four chucks, but also offer global users heavy tube cutting solutions beyond expectation.

- Combine C3 and C4 chuck together with synchronous rotation and moving

- Have functions of tube clamping, supporting and correction

- Move at full stroke

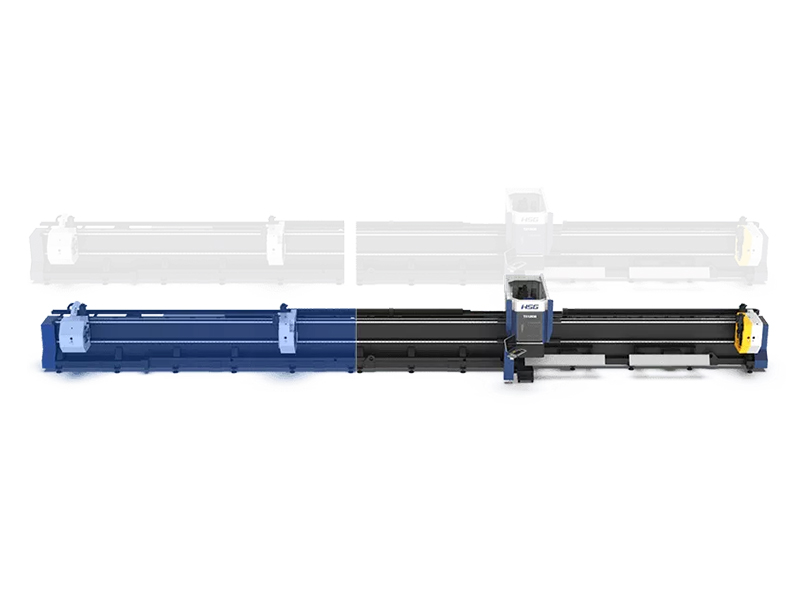

Lateral Hanging Machine Bed

The machine bed is made of several sections and spliced together, therefore, long tube is also easily processed. Due to co-axial treatment, the machine can make sure of its running precision. Notes: It is suitable for TX9036, TX12036 and TX12050.

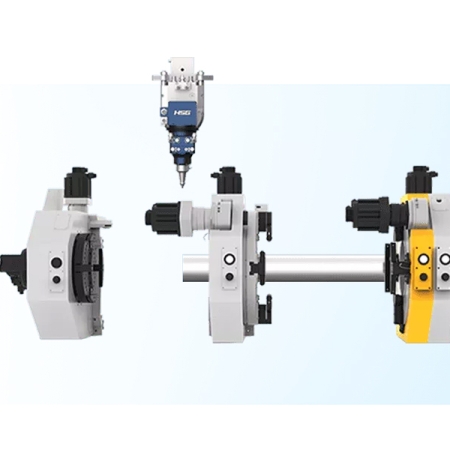

Shaped Last Cut Technique

When work procedures are well arranged, zero tailing comes ture to save material purchasing costs.

Follow-up Supporting Plate as Unloading Device

Follow-up supporting plate and concave wheel are used for unloading ≤6000mm long tube. The plate provides support to dropping tubes to avoid scratch.

Dust Removal

There are air hoses on the front chuck and high-power exhaust fans that work together to cut down smoke pollution and keep operators healthy.