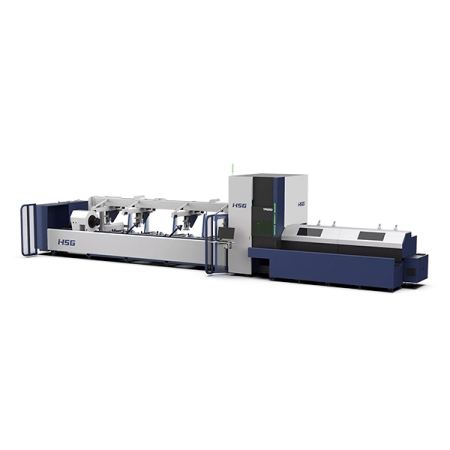

Leading innovation, High power, High Speed.

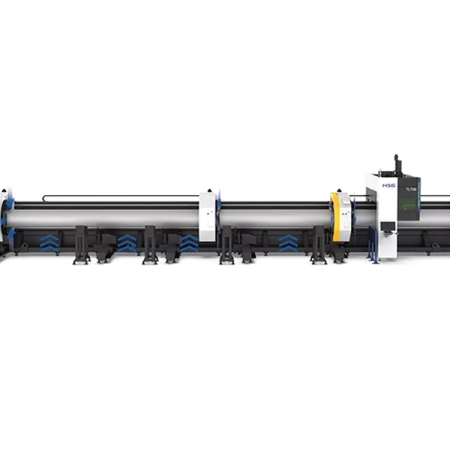

The HSG Laser TLS Series is their leading flagship series. The innovative “4+1” chuck structure combines C3 and C4 chucks into one for dual support. The loading end is clamped with four points for significant load improvement. The TLS Series single tube loading capacity can reach 4 tons, and the maximum processing tube diameter is 715mm. With 20000W high-power cutting and bevel cutting, the cutting thickness and speed are significantly improved, and the bevel processing can be completed in one pass, saving steps.

Why the HSG TLS Series Full Track Tube Beveling Fiber Laser Cutting Machine?

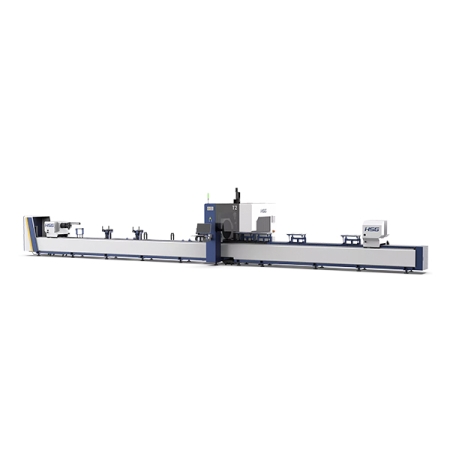

- Hydraulic lifting exchange system – German brand hydraulic station

- All linear motor drive in X axis, Y axis, Z axis

- High power special bed full sheet welding and hollow structure

- Various and intelligent modes: visual edge seeking, automatic nozzle replacement for improving experiences and processing efficiency of users

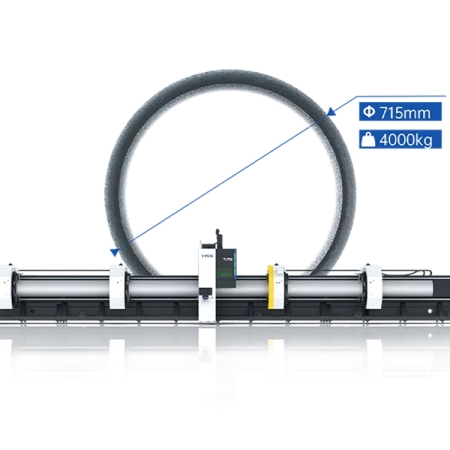

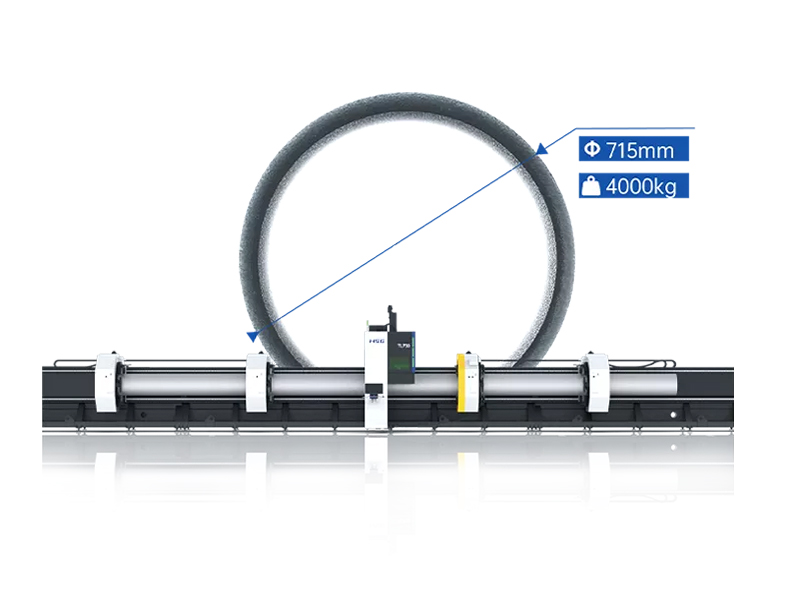

Max Heavy-duty Tube Processing Ability

The machine can process tube diameters in 715mm.

- Tube Length:16m

- Weight per Tube: 4000kg

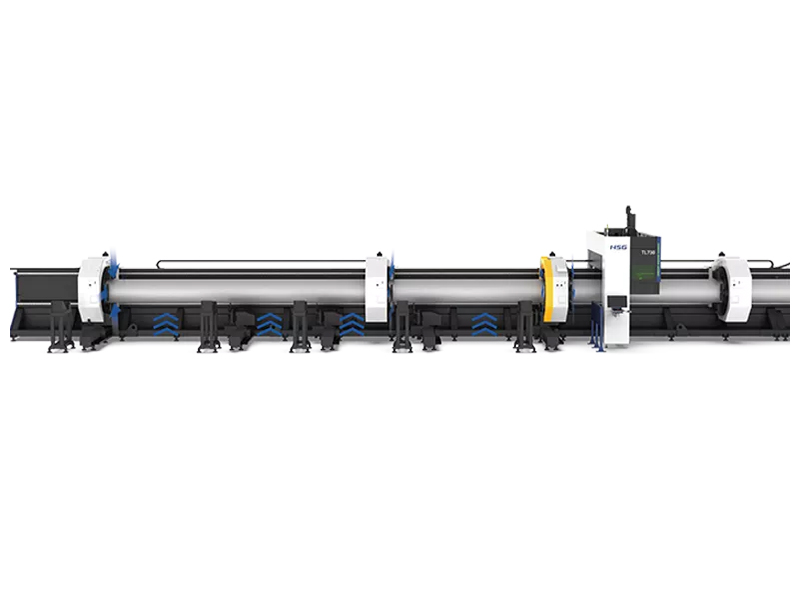

Innovate 4+1 Chucks Structure

- C3 chuck and C4 chuck are combined to achieve double support

- There are 4 points clamping at loading section and the load bearing improved significantly

- Clamping near the cutting area at 2 points which the accuracy is effectively guaranteed.

Intelligent digital chuck

- The chuck and the control system can communicate with each other to achieve full closed-loop control.

- The machine has functions in jaw state detection, tube size measurement and adaptive adjustment of clamping force.

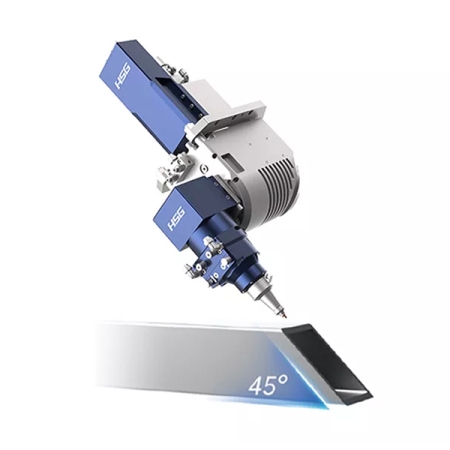

Beveling Processing

HSG-LA4 tube beveling tube cutting head to achieve 0-45°beveling cutting.