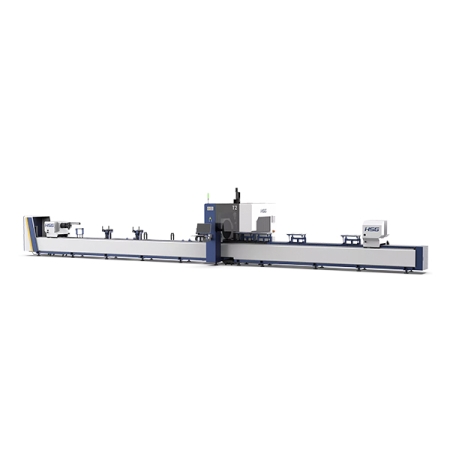

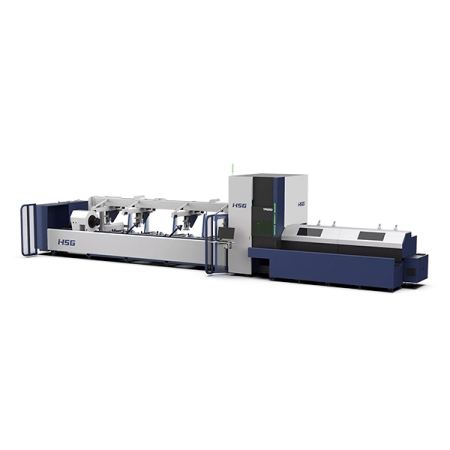

Powerful, High Speed, Exceptional Accuracy and Reliability.

The HSG Laser TS Series is a powerful laser cutting machine that ensures accuracy and speed in processing a large range of cutting thicknesses. HSG pride themselves on using the highest quality component parts at the most affordable price. Their strict quality processes ensure high speed cutting of exceptional accuracy and reliability. It has a pneumatic chuck with intelligent digital feedback that alerts if the chuck does not clamp the profile properly. The TS Series can be delivered with the machine itself as a base, or together with an automation solution for loading and unloading. The TS series is known for its fast cutting speeds and serves as an epitome of HSG’s super tube cutting level and technology.

Why the HSG TS Series High-Speed Tube Fiber Laser Cutting Machine?

- High speed and intelligent for better processing

- X9500 Bus-based tube cutting control

- Powerful functions so you’ll never spend time worrying

- Tube splicing technology

- Tube clamping technology

- Cut tubes at higher speeds

Cut Tubes at High Speed

The chucks rotate and move at the speed of 120r/min and 120m/min respectively. With that, users will enjoy fast cutting, stable services and high production.

Tube Splicing Technology

The operating control offers 50+ kinds of tube splicing patterns, for convenience of subsequent welding, such as splicing of male and female head of square tube, 90° arc splicing, splicing of round tube tee, splicing of cut-through holes, 45° splicing of hexagon , splicing of angle iron and channel steel, etc.

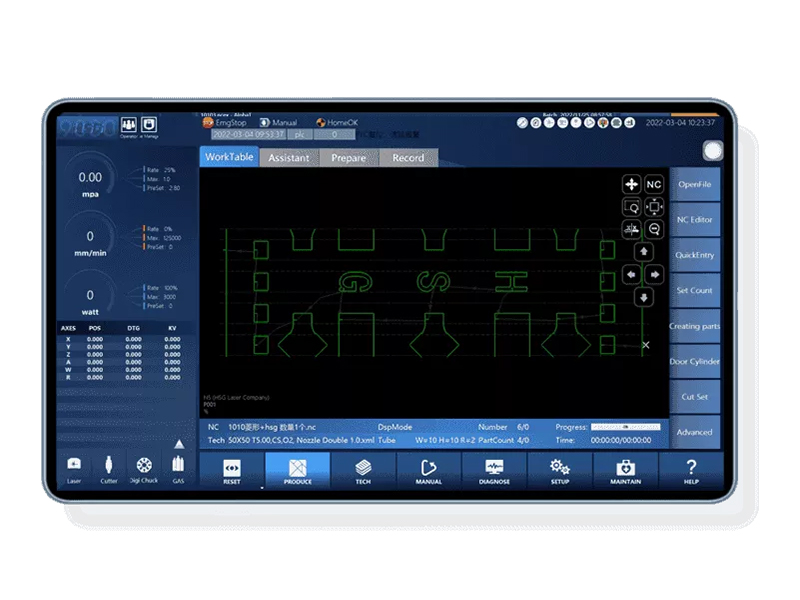

HSG-X Bus Control System

HSG-X control system is bus-based and developed by HSG Laser. With intelligent and easy-to-operate service, it can offer users effective solutions to address problems of difficult operation, low efficiency and high costs.

Automatic Unloading Device

- Turning plate height can be manually adjusted by users to fit for unloading different types of tubes.

- Concave supporting frame is available to protect tubes from scratch.

Digital Controlling Pneumatic Chucks

- With wireless digital feedback, chucks combine with system to form closed-loop controlling

- High clamping speed, accuracy and working efficiency , low threshold pressure

- Wireless monitoring of chucks, alarm for empty chucks and high security for no collision between chucks and work-pieces

- Pressure adjustments depending on different tube diameters and thicknesses

- Intelligent chucks in full track without artificial adjustments and the load-bearing can achieve 200kg.