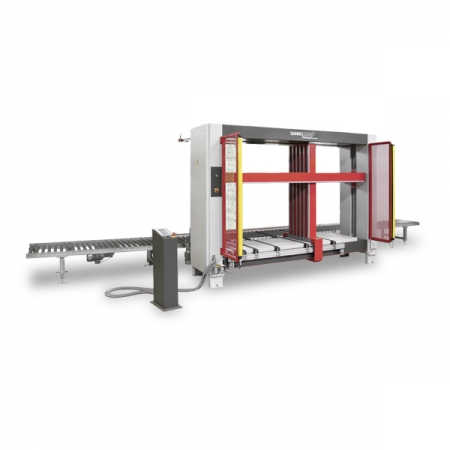

A compact space saving case clamp capable of clamping single or multiple case goods

The Gannomat Concept Easy solid platen case clamp is specially designed to save time and labor in dowel construction cabinet assembly operations. Whether it is your only clamp or a second clamp the Gannomat Concept Easy will improve your cabinet assembly throughput. Available in configurations with working heights of 1700mm or 2500mm.

Why Gannomat Concept Easy Case Clamp?

- Vertical design requires minimal floor space

- Excellent value for an electronically controlled solid platen case clamp

KEY ADVANTAGES

- Continuous working surfaces (fixed sidewall and side pressure beam), eliminates set up time for carcasses with fixed shelves, stretcher rails etc. and small carcasses like e.g. drawer-boxes

- Simple operation by push buttons allows the operator to set the clamping pressure, clamping time, and opening / closing of the press

- Equipped with timer which indicates the end of the pressing cycle to tell the operator when to open the press.

- Adjustable pressing force with selector-switch for optimum pressure

- 90° angle at the carcass is ensured through the sturdy durable steel frame

- Pressing force is exerted along the horizontal axis of the dowel joint by the side pressure beam. Most carcasses only require this single-directional clamping.

- Several carcasses of the same width can be pressed in one operation

- Wide spaced precision ball-bearing guides ensure the stability of the pressing beam

- Adjustable clamping speed can be suited to your needs

- Green indicator light displays when set pressure is reached

SPECIFICATIONS

Akhurst Machinery Group announces strategic partnership to aid North American housing crisis.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the North American machinery industry, is pleased to announce a strategic partnership with Modular Building Automation (MBA), a Dutch company specializing in machinery for prefabricated homes, modular buildings, and offsite construction solutions. MBA, a joint venture of the renowned companies J.J. Smith in the UK and Ireland and H&M headquartered in the Netherlands, is involved in the design, manufacturing, distribution, and worldwide sales of MBA equipment.

Akhurst Machinery Group announces strategic partnership with Stromab.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the machinery industry, proudly announces a strategic partnership with Stromab SPA, an Italian manufacturer of innovative crosscutting solutions. This collaboration signifies a major commitment by both companies to bring cutting-edge technology and comprehensive solutions to the North American market. Akhurst Machinery Group, the parent company behind the well-known brands of Cantek and Leadermac USA, will leverage Stromab SPA’s expertise in crosscutting solutions to enhance its offerings in North America.

Woodworking Technology Days 2023 is just around the corner.

Corporate, Machinery Solutions, Trade ShowsVisit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.