It is time to upgrade your cabinetry with precision dovetail drawer boxes.

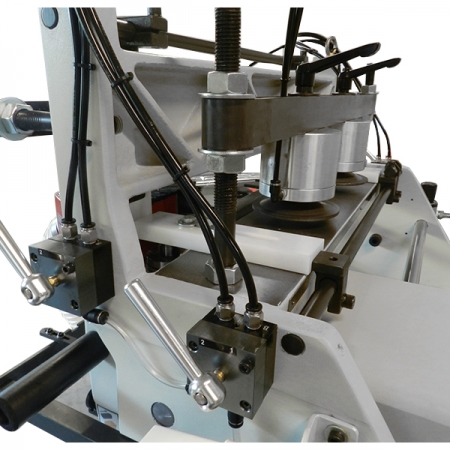

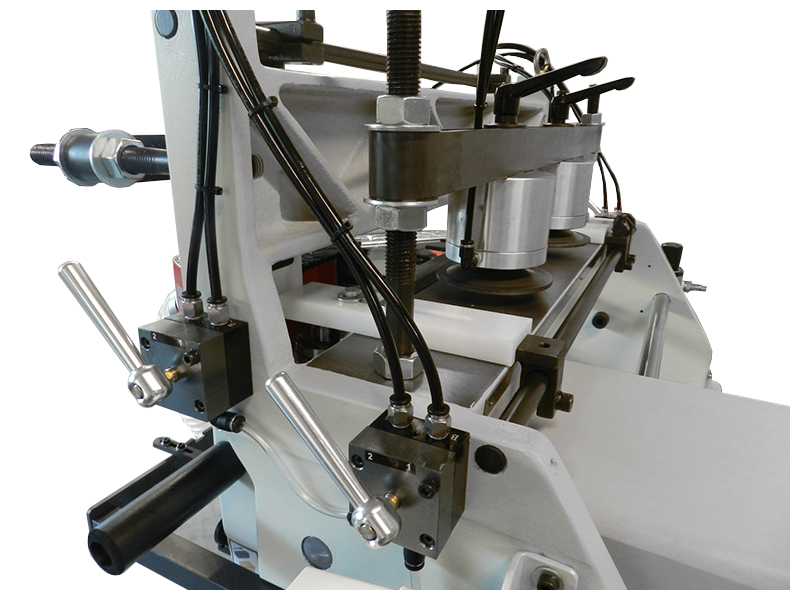

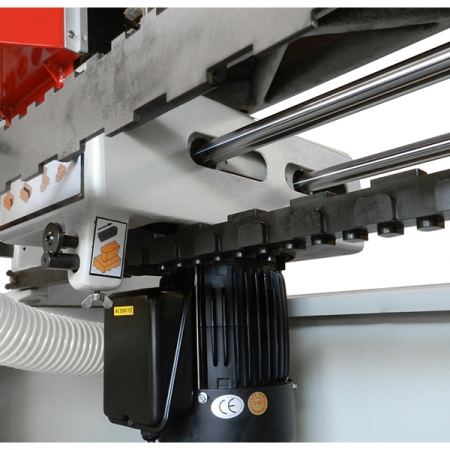

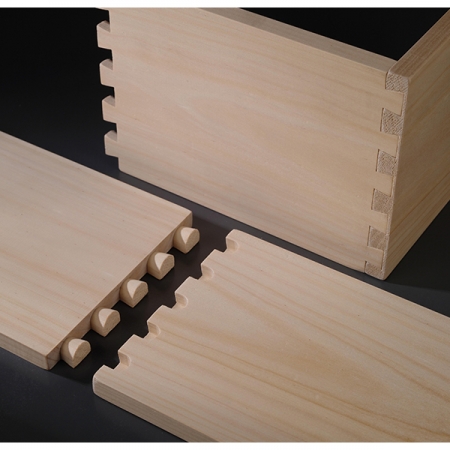

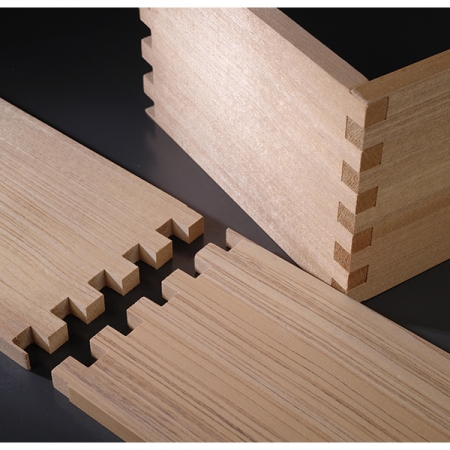

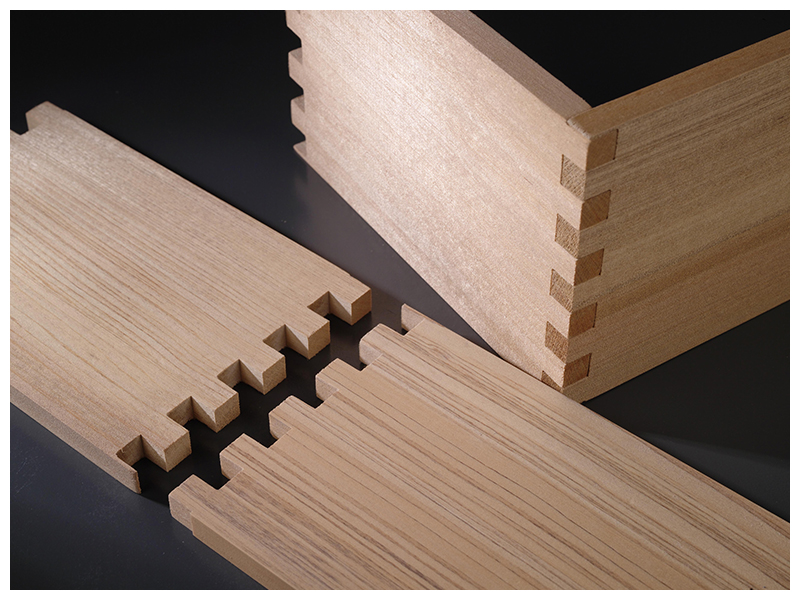

Add prestige to your cabinets with aesthetically pleasing dovetail drawer boxes with the Cantek JDT65 manual dovetailer. Dovetails display your quality and are built to last! Producing beautifully aesthetic dovetails for drawer box production from a wide range of wood types, including plywood and solid wood. The JDT65 machine produces both the pin and tail of the dovetail simultaneously. All four sides of the drawer can be loaded into the machine for optimum production capacity. The operator controls the dovetail unit by following a simple template allowing for ease of operation and quality joints. Equipped with a choice of four pitch templates for varying types of dovetail joints.

Why Cantek JDT65 Manual Dovetailer?

- Ideal for drawer production and furniture parts which require high quality dovetail joints.

- Workpieces are pneumatically clamped to speed up material changeovers

- Equipped with one four-sided template providing four pitches between dovetails.

- Floating dovetailing unit has ball bearings which run on chrome steel guiderails for effortless operation

- Standard pitch 1″, 1 ½”, 2″ and 2 ½”

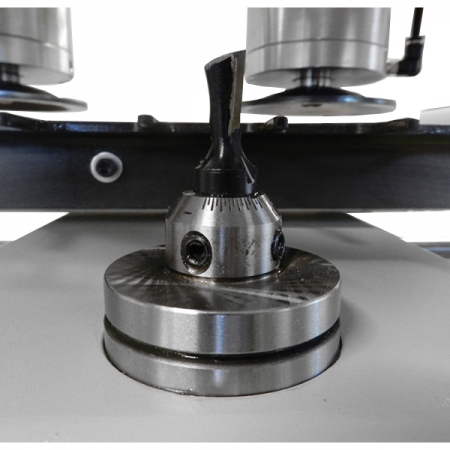

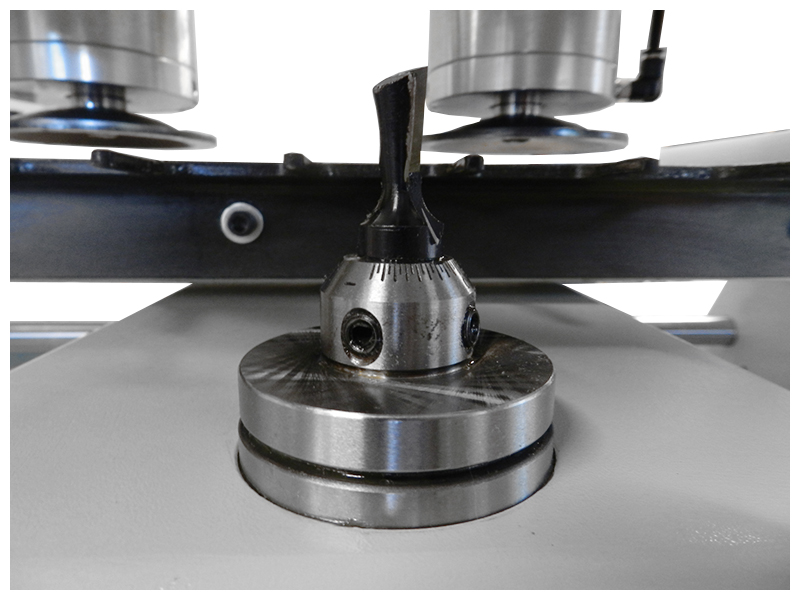

- Solid carbide single flute eccentric dovetail bit controls the fit of the joint

- 18500 RPM spindle for superior cut quality

- Max. workpiece size 59″ x 16 ½”

- Workpieces are clamped by air clamps

- Equipped with an indication bar for indicating cutting position

- Tenon and mortise depth are conveniently adjusted according to the thickness of workpiece

- The spindle accommodates 12 mm TCT eccentric cutter

- Enclosed base

- Magnetic switch with thermal overload protection

Dovetails, what’s the big deal?

Machinery SolutionsOnce you open the drawer and see the dovetail design, it elevates your product in the consumer’s eye. But why dovetail machine is right for my operation? When deciding to produce your own drawer boxes, a number of factors come into play when selecting the equipment required.

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.

Kingswood Cabinets. A true commitment to growth.

Case Study, Machinery Solutions, Service and SupportAkhurst is very proud of our involvement in the plant expansion of Kingswood Cabinets of Calgary, Alberta. Kingswood recently relocated to a new state-of-the-art manufacturing facility.