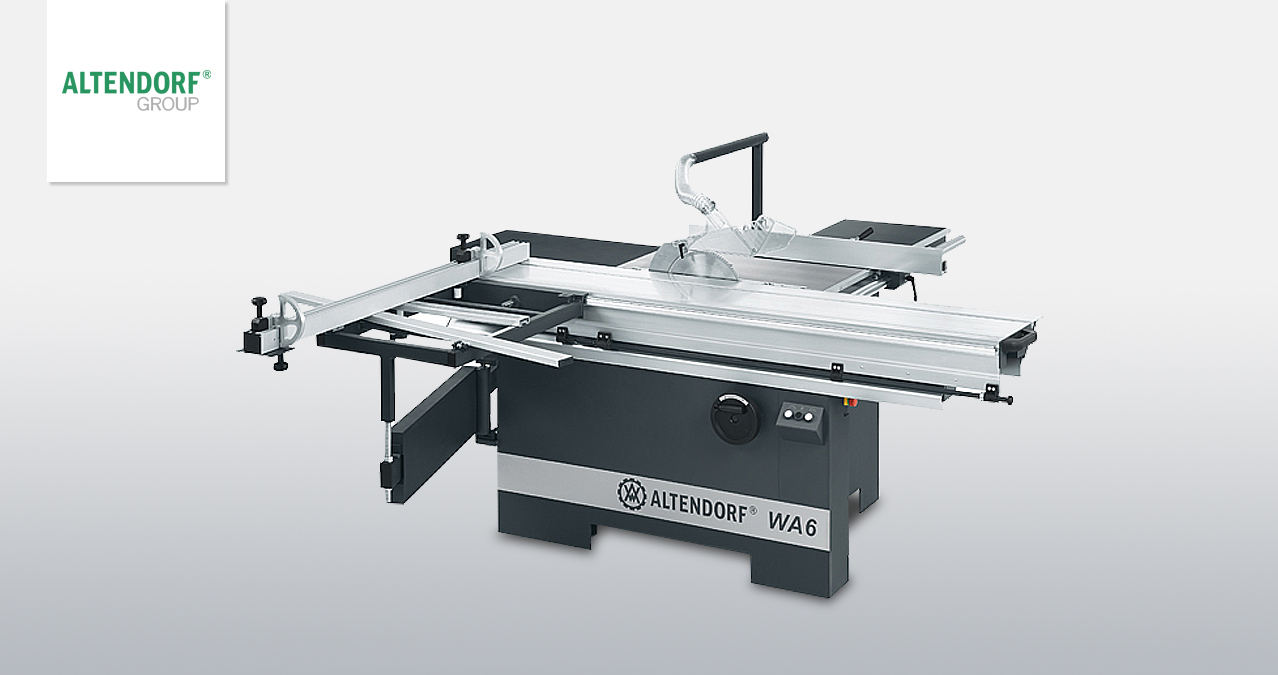

Altendorf Quality & Precision at a Lower Price.

The Altendorf WA6 Sliding Table Saw was designed for users with limited space and budget, but don’t want to comprise on quality.

Small in size, the WA 6 captivates as well as all other machines from Altendorf by high-quality workmanship, innovative features and on top of that by an unbeatable price. Suitable for both beginners and professionals, the Altendorf WA 6 makes working on the sliding table saw one of your easiest exercises.

The WA 6 is the smallest Altendorf sliding table saw available. And despite its smaller dimensions, it impresses with great performance: With its strong features, it trumps even in the smallest space big. Outstanding are the cutting quality and the flexibility in daily use. And just as outstanding is the price.

Why Altendorf WA6 Sliding Table Saw?

- Altendorf quality at a budgetary price

- Powerful 5.5 HP main motor with separate ½ HP scoring motor

- Manual rise / fall / tilt

- Equipped with the proven Altendorf sliding table with steel bar guidance for smooth table movement.

- Choice of 1600, 2000, or 2600mm long sliding table (2600mm normally stock)

- Sliding table: The proven Altendorf sliding table with steel bar guidance. The WA 6 is available with 1600, 2000 or 2600 mm sliding table.

- Rip fence: The rip fence, smooth and precise. Cutting width: 1000 mm

- Crosscut-mitre fence: For accurate angle and mitre cutting in a single function. Cutting lengths: 105 – 2600 mm. Mitre angle infinitely adjustable by up to 49°.

- Manual tilt adjustment: manual with hand wheel, tilt angle indicated on a scale. From 0 – 45°.

- Manual rise/fall adjustment: manual with hand wheel.

- Scorer: Separate 0.37 kW scoring motor with on/off switch.

- Safety hood: Safety hood for max. saw blade diameter of 315 mm (CE version) bzw. 350 mm (non-CE version), mounted on the riving knife, with extraction hose above the main saw blade. Max. saw blade projection 100 mm bzw. 117,5 mm.

- Motor rating: Drive: 4 kW (5.5 HP) Speed: 4200 RPM

Pre-milling for Edgebanders.

Machinery SolutionsMore often today you are finding features on smaller edge banders that initially were exclusive to larger, higher production machines. One of those features is pre-milling. Pre-milling consists of two counter-rotating cutterheads which are designed to mill the edge of the panel prior to applying the edge banding material.

Proper edgebander maintenance.

Machinery SolutionsEdgebanders are one of the more complex machines in operation in most cabinet and millwork shops. The maintenance however is imperative to the performance and reliability of the machine. Without it you can experience a poor edge quality which will result in hand finishing and defects and worst of all significant down time and expense […]