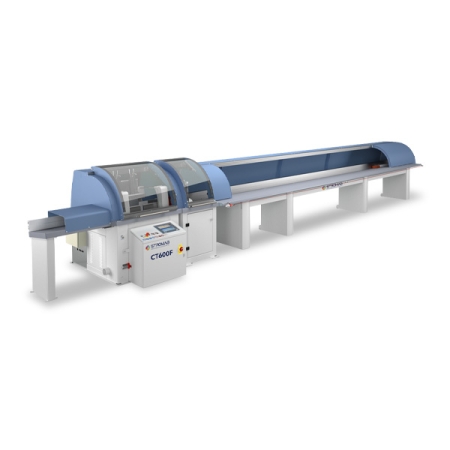

A cut-off saw designed for versatile use, delivering exceptional performance and precision.

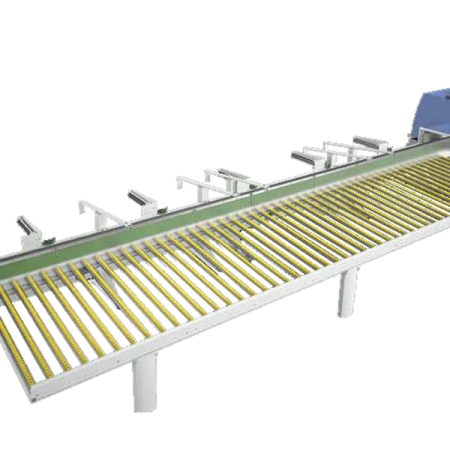

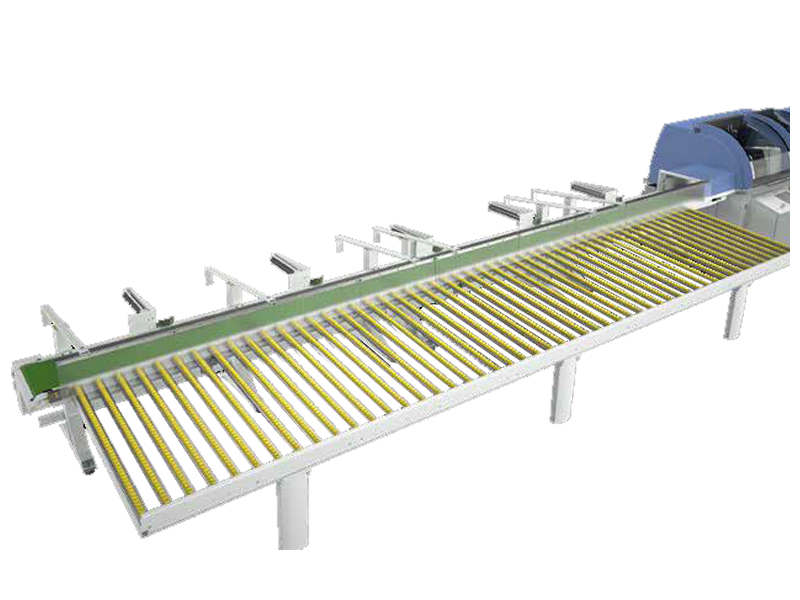

The Stromab TR500F MATRIX Automatic Push Feed Straight Crosscut Saw with Milling Unit is a straight cut-off saw with an innovative electronic push feed system and controlled axis. This state-of-the-art machine blends the reliability of a pneumatic cut-off saw with an ascending blade, an electronic push feed system, a precise rack and pinion guide system, and a milling unit upgrade. The saw’s standard “OPTI” solution boasts an array of six uniform-length optimization options: (Maximum length, Sequence, Board sequence, Volume, Minimum ). Its motor system contains a brushless motor and a planetary reduction unit, coupled with a precision encoder for unparalleled accuracy. Our diverse array of options spans lengths ranging from 6 1/2 ft to 43 ft, encompassing both left-hand and right-hand push feed configurations and an extensive array of supplementary components.

Why Stromab TR500F MATRIX?

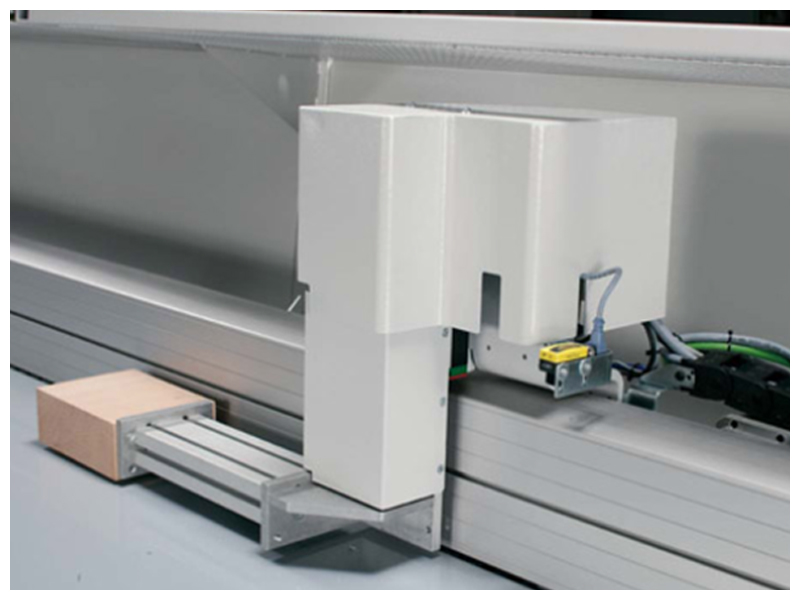

- Milling unit for making notches up to 400 x 100 x 75 mm (15.8 x 3.9 x 3”)

- Heavy duty rack and pinion material pusher system for fast and accurate positioning with high repeatability resulting in maximum productivity

- The pusher is driven by a brushless motor and planetary reduction unit, coupled with a precision encoder for unparalleled accuracy

- Efficient cutting cycle of 4 seconds

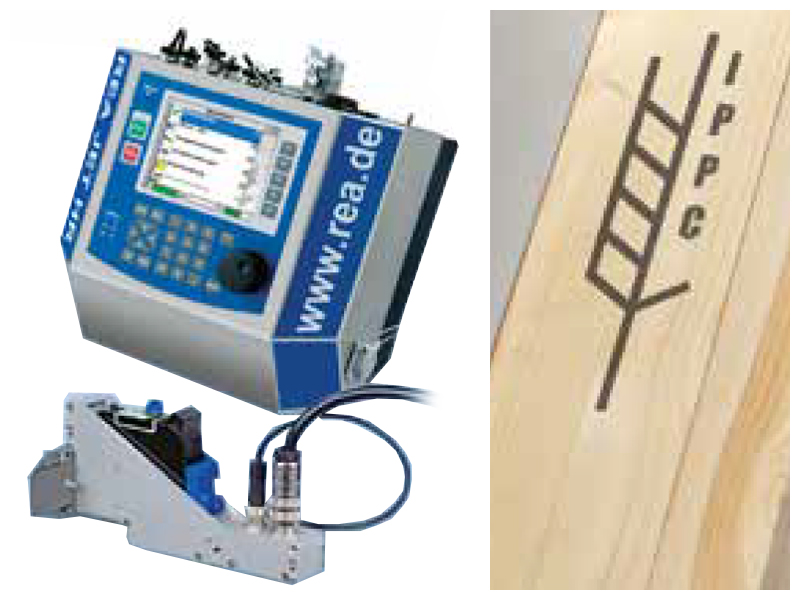

- Equipped with a 12” touch-screen controller, with USB, Ethernet ports, and a Beckhoff operating software system with Windows 7

- Ample storage capacity, accommodating up to 10,000 cutting lists with the ability to load and save machine parameters via USB

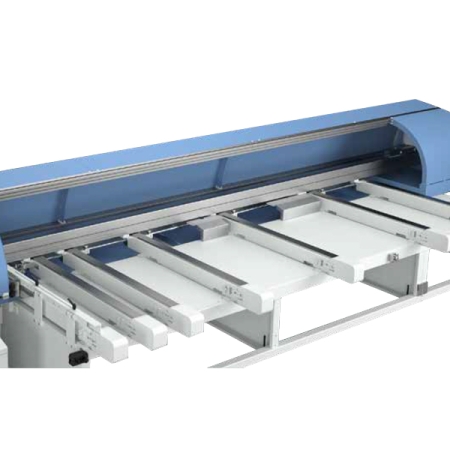

- Loading and unloading units on both the left and right sides of the cutting unit

- Pneumatic rising of the pusher at the end of the cutting cycle and overhead returning

- Two versions “OPTI”, and “OPTI PLUS”, each offering integrated solutions to cater to diverse needs

- Four standard infeed and outfeed capacity length options: 10, 13, 16, and 20 ft

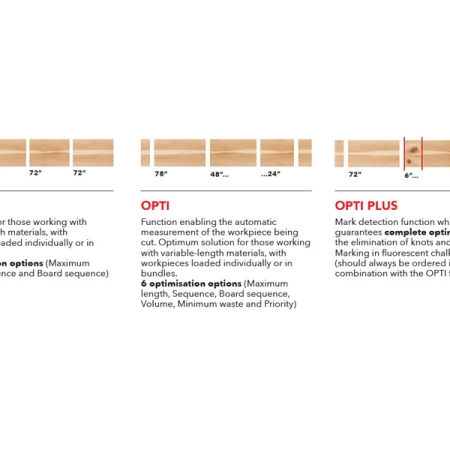

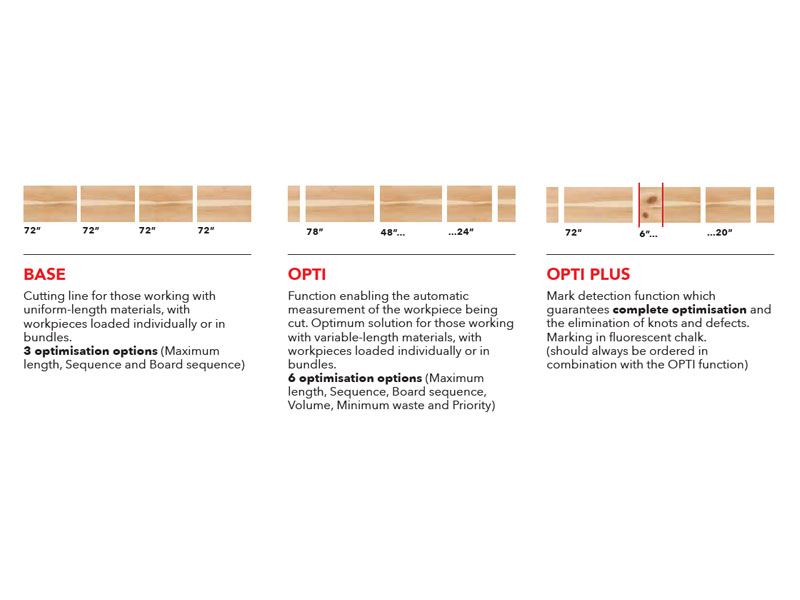

- “BASE”: The saws standard “base” solution boasts an array of three uniform-length optimization options: Maximum length, Sequence, and Board sequence

- “OPTI”: For automatic board length detection and full optimization – upgrading from 3 optimizing options to 6: (Longest length, Sequence, Board sequence, Volume, Minimum waste, and Priority length)

- “OPTI PLUS”: For advanced mark detection ensures complete optimization while eliminating knots and defects. The system marks the material with fluorescent chalk, enhancing precision and quality.

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.