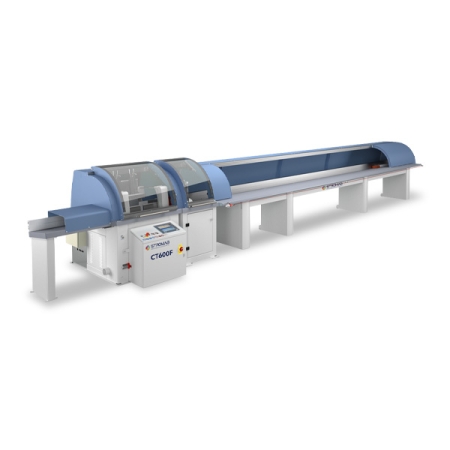

A cut-off saw designed for versatile use, delivering exceptional performance and precision.

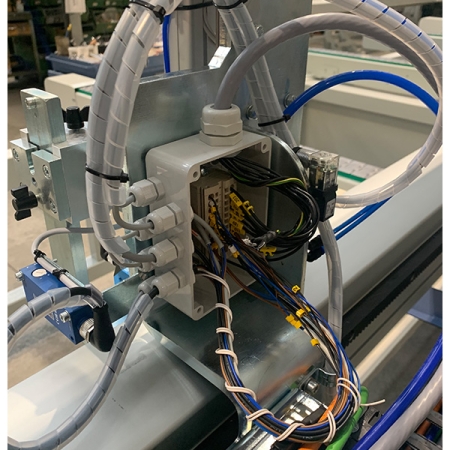

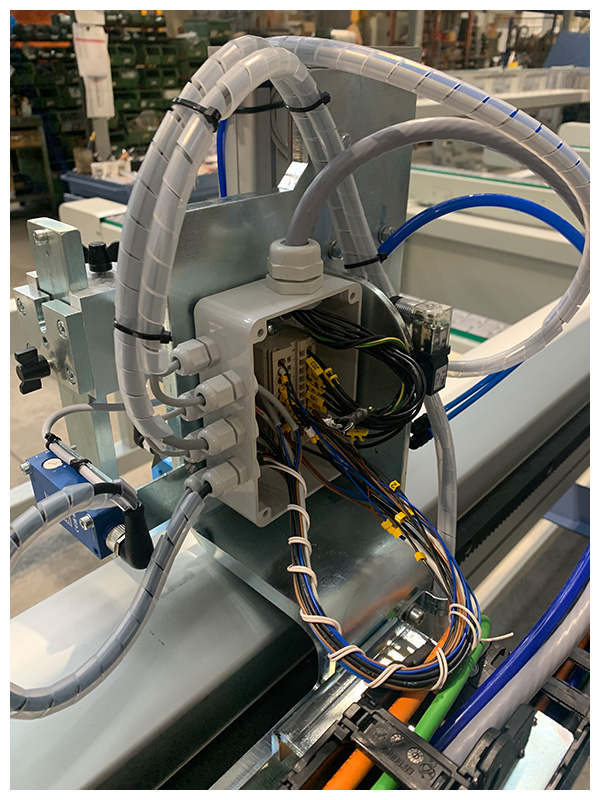

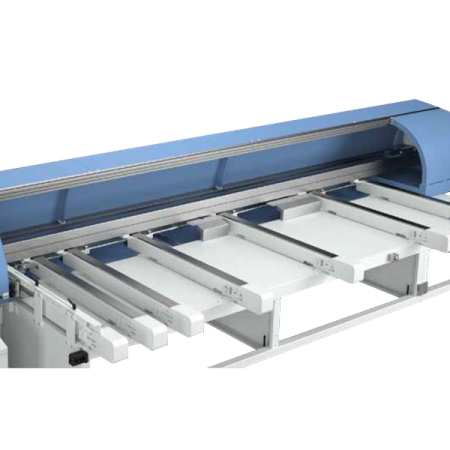

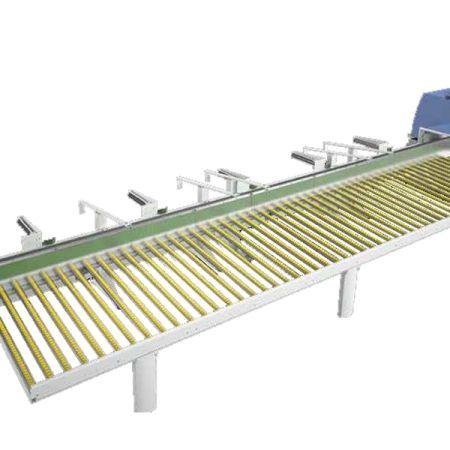

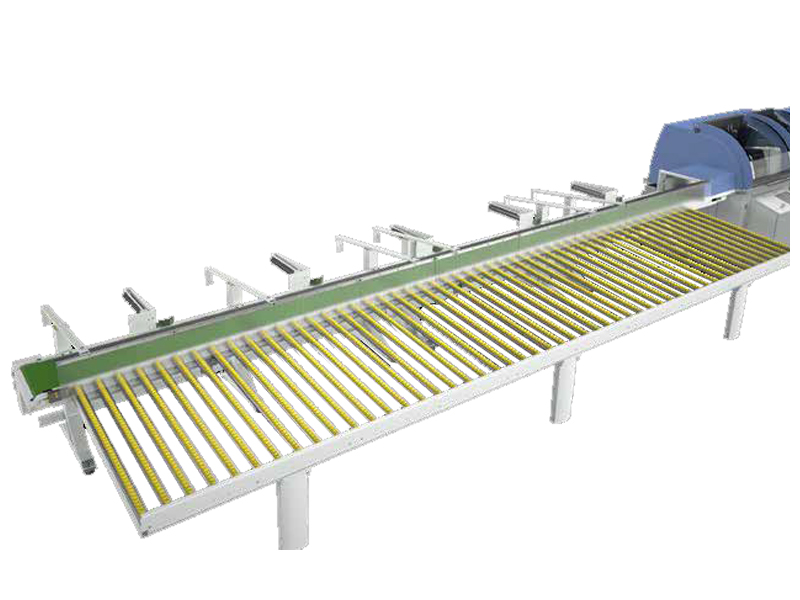

The Stromab TR500 MATRIX is a straight cut-off saw with an innovative electronic push feed system and controlled axis. This state-of-the-art machine blends the reliability of a pneumatic cut-off saw with an ascending blade, an electronic push feed system, and a precise rack and pinion guide system. The saw’s standard “base” solution boasts an array of three uniform-length optimization options: (Maximum length, Sequence, and Board sequence). Its motor system contains a brushless motor and a planetary reduction unit, coupled with a precision encoder for unparalleled accuracy. Our diverse array of options spans lengths ranging from 6 1/2 ft to 20 ft, encompassing both left-hand and right-hand push feed configurations and an extensive array of supplementary components

Why Stromab TR500 MATRIX?

- Heavy duty rack and pinion material pusher system for fast and accurate positioning with high repeatability resulting in maximum productivity

- The pusher is driven by a brushless motor and planetary reduction unit, coupled with a precision encoder for unparalleled accuracy

- Efficient cutting cycle of 4 seconds

- Equipped with a 12” touch-screen controller, with USB, Ethernet ports, and a LINUX operating software system

- Ample storage capacity, accommodating up to 10,000 cutting lists with the ability to load and save machine parameters via USB

- Loading and unloading units on both the left and right sides of the cutting unit

- Pneumatic rising of the pusher at the end of the cutting cycle and overhead returning

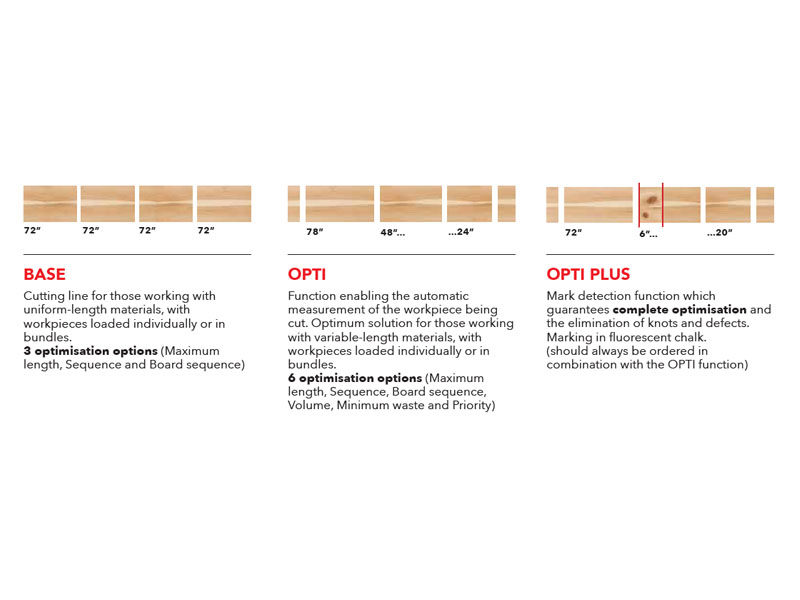

- Three versions, “BASE”, “OPTI”, and “OPTI PLUS”, each offering integrated solutions to cater to diverse needs

- Four standard infeed and outfeed capacity length options: 10, 13, 16, and 20 ft

- “BASE”: The saws standard “base” solution boasts an array of three uniform-length optimization options: Maximum length, Sequence, and Board sequence

- “OPTI”: For automatic board length detection and full optimization – upgrading from 3 optimizing options to 6: (Longest length, Sequence, Board sequence, Volume, Minimum waste, and Priority length)

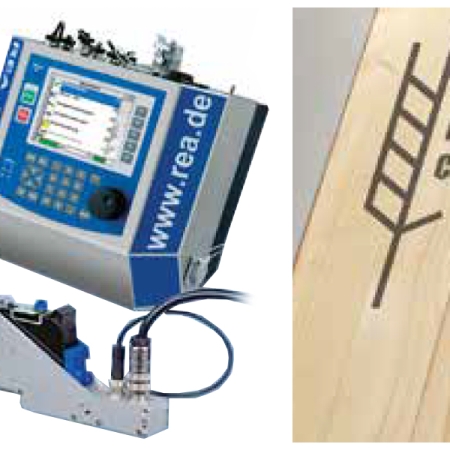

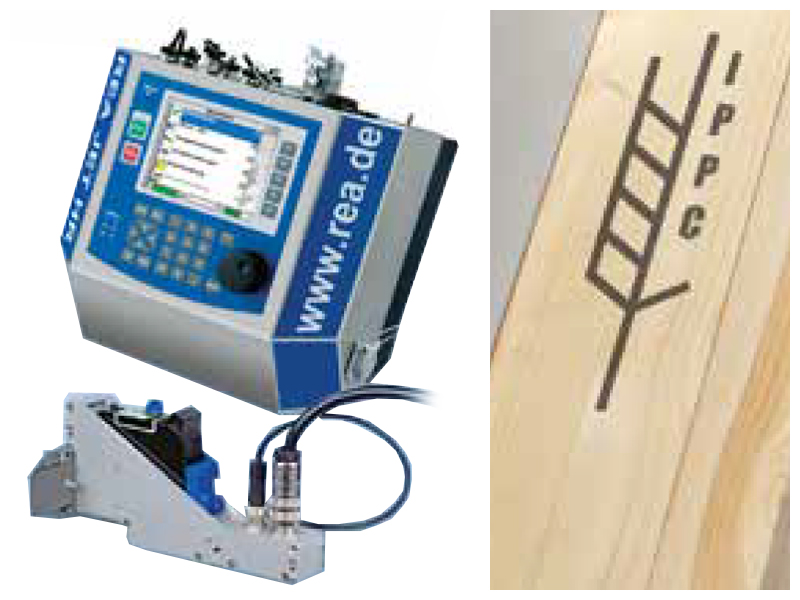

- “OPTI PLUS”: For advanced mark detection ensures complete optimization while eliminating knots and defects. The system marks the material with fluorescent chalk, enhancing precision and quality.

AKHURST MACHINERY GROUP ANNOUNCES EXCLUSIVE DISTRIBUTION PARTNERSHIP WITH MARINUS MACHINEBOUW

Corporate, Machinery SolutionsAkhurst Machinery Group, a distinguished leader in the North American machinery industry, is excited to announce a significant milestone in their longstanding strategic partnership with Marinus Machinebouw, as they are selected as the exclusive distributor of Marinus for North America.

Akhurst Machinery Group announces strategic partnership to aid North American housing crisis.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the North American machinery industry, is pleased to announce a strategic partnership with Modular Building Automation (MBA), a Dutch company specializing in machinery for prefabricated homes, modular buildings, and offsite construction solutions. MBA, a joint venture of the renowned companies J.J. Smith in the UK and Ireland and H&M headquartered in the Netherlands, is involved in the design, manufacturing, distribution, and worldwide sales of MBA equipment.

Akhurst Machinery Group announces strategic partnership with Stromab.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the machinery industry, proudly announces a strategic partnership with Stromab SPA, an Italian manufacturer of innovative crosscutting solutions. This collaboration signifies a major commitment by both companies to bring cutting-edge technology and comprehensive solutions to the North American market. Akhurst Machinery Group, the parent company behind the well-known brands of Cantek and Leadermac USA, will leverage Stromab SPA’s expertise in crosscutting solutions to enhance its offerings in North America.