Shot Blasting for Structural Steel.

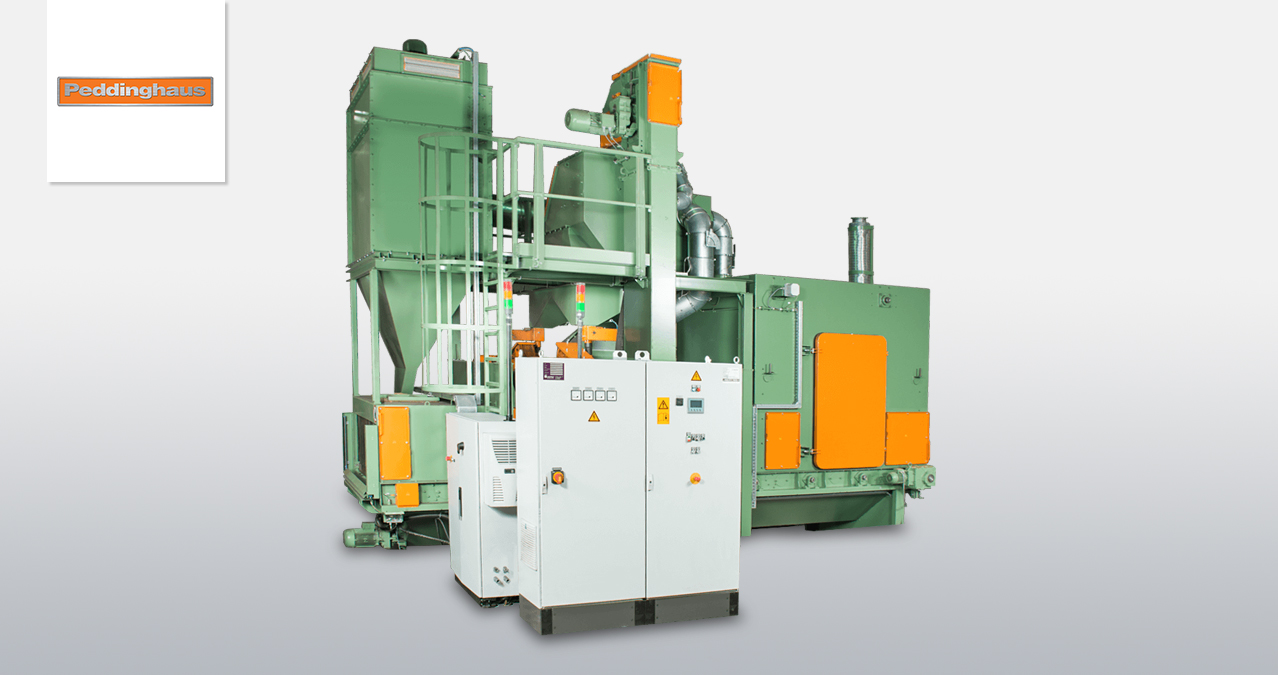

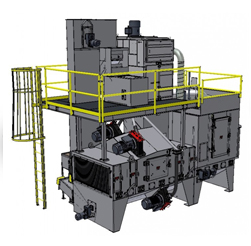

In all shops, small or large, the Peddinghaus PeddiBlast Shot Blast Machine is completely configurable to each fabricators’ needs. It is designed to be easily integrated into new or existing shop layouts while utilizing the most sophisticated and robust shot blasting technology. The PeddiBlast has proven to be unrivaled in durability during blasting processes.

Why Peddinghaus PeddiBlast Shot Blast Machine?

- Partnered with Agtos to create the best blasting machine for structural steel facility

- Utilizes adjustable air flow to pass through the heavy abrasive and remove any small particles

- Protected by manganese steel to keep entry points from wear

- Large blasting hotspot, not offered on any other single disk design turbine

- PeddiBlast turbines are strong power units which are highly cost effective due to fewer wear parts and a high abrasive flow

- Complete control of blasting process from control interface

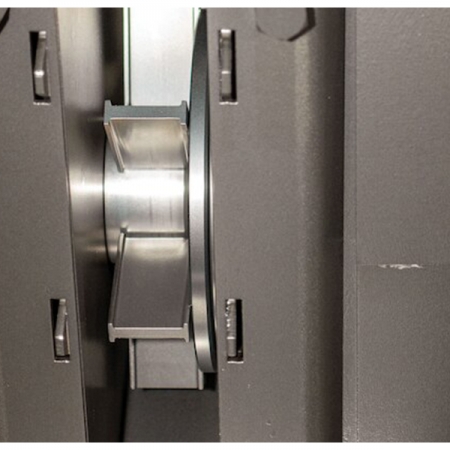

Powerful Blasting Turbine

Turbines on the PeddiBlast shot blast machine fall nothing short of strong, cost-effective power units. With blades built from tough manganese steel, the turbine housing is wear-resistant. This ensures the turbine will be able to operate for prolonged periods of time between services.

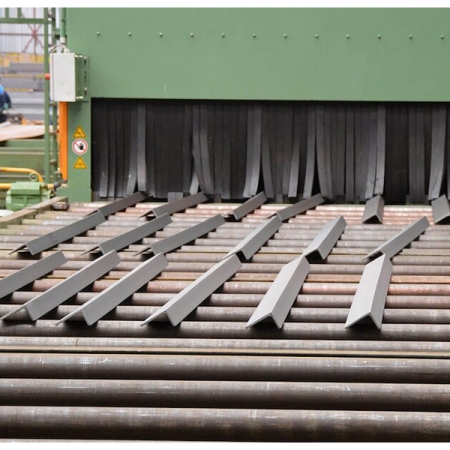

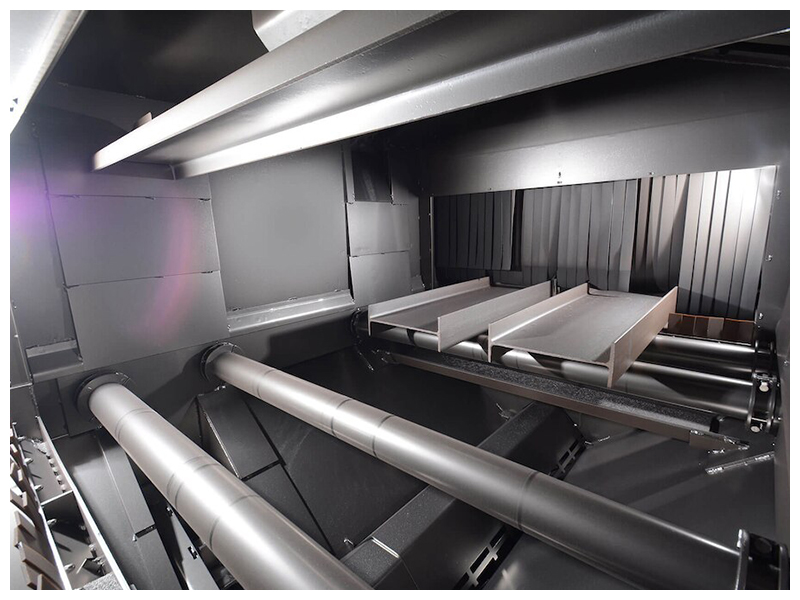

Protective Blast Chamber

Designed to give the turbines unobstructed paths to material being processed within, the chamber ensures successful blasting procedures every time. Abrasive is fed to the turbines via shell valves designed to regulate abrasive flow and limit abrasive consumption, ultimately reducing operating costs.

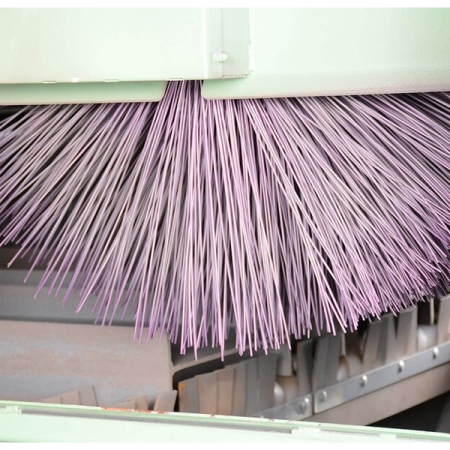

Abrasive Containment Curtains Keep Operators Safe

Each compartment within the PeddiBlast is outfitted with abrasive containment curtains designed to keep abrasive off the shop floor and keep operators safe from slips and falls.

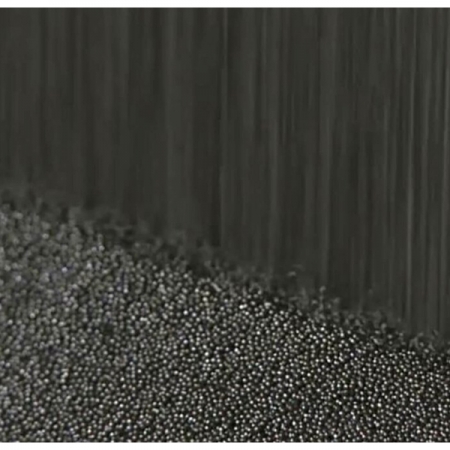

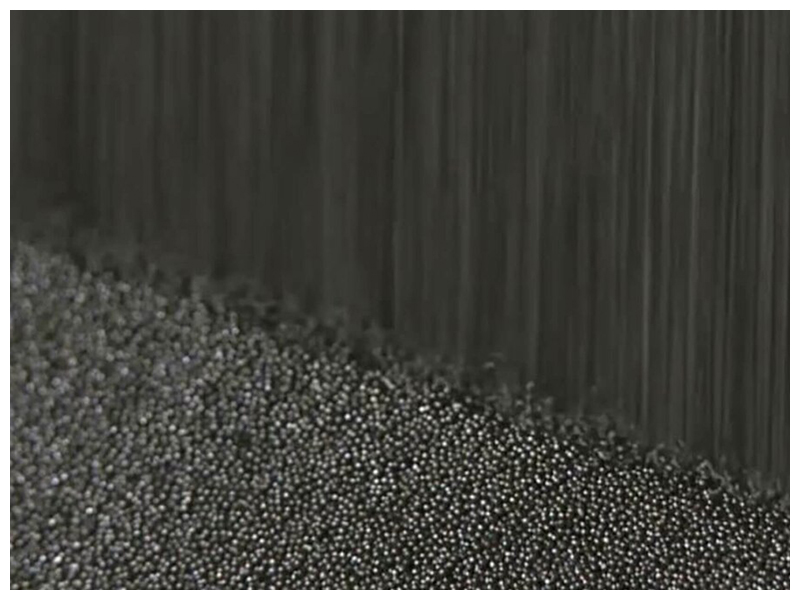

Bucket Elevator and Wind Separator

A bucket elevator effectively transports new and used abrasive up to the filters of the machine. Separating dust particles and worn out shot reduces the wear on the machine and results in a better blast quality.

Dovetails, what’s the big deal?

Machinery SolutionsOnce you open the drawer and see the dovetail design, it elevates your product in the consumer’s eye. But why dovetail machine is right for my operation? When deciding to produce your own drawer boxes, a number of factors come into play when selecting the equipment required.

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.

Kingswood Cabinets. A true commitment to growth.

Case Study, Machinery Solutions, Service and SupportAkhurst is very proud of our involvement in the plant expansion of Kingswood Cabinets of Calgary, Alberta. Kingswood recently relocated to a new state-of-the-art manufacturing facility.