Shot Blasting for Structural Steel.

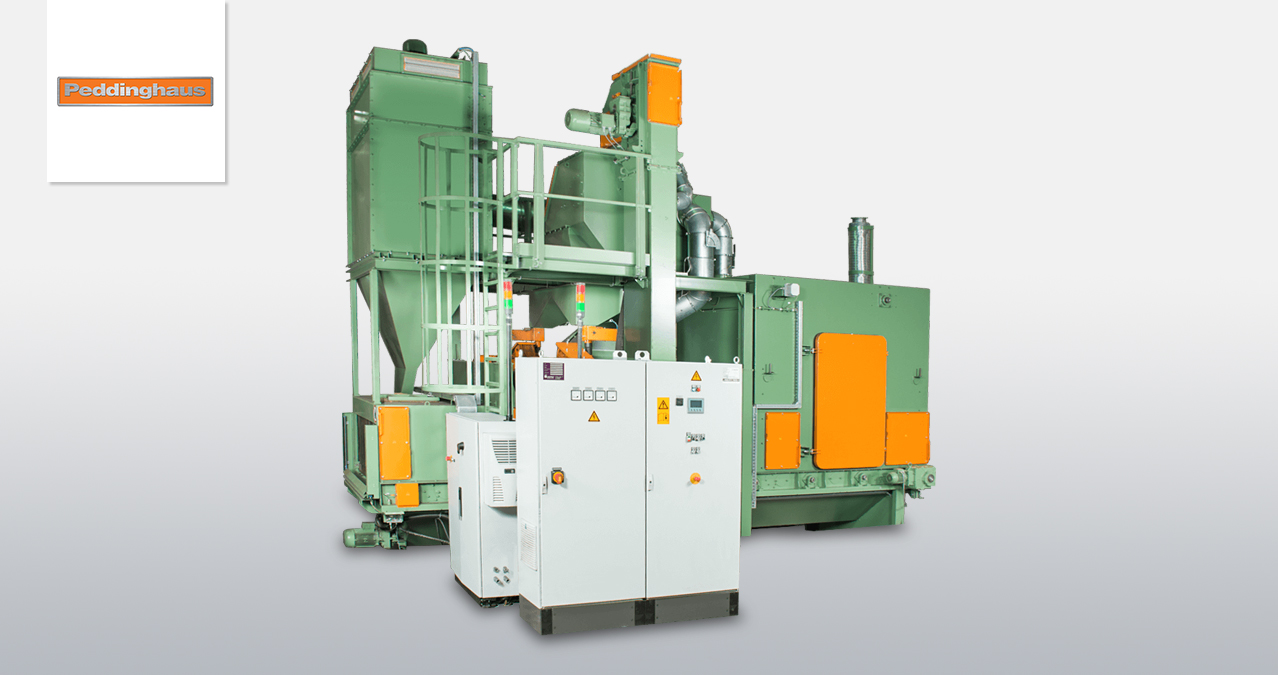

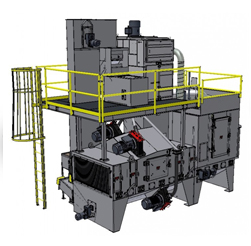

In all shops, small or large, the Peddinghaus PeddiBlast Shot Blast Machine is completely configurable to each fabricators’ needs. It is designed to be easily integrated into new or existing shop layouts while utilizing the most sophisticated and robust shot blasting technology. The PeddiBlast has proven to be unrivaled in durability during blasting processes.

Why Peddinghaus PeddiBlast Shot Blast Machine?

- Partnered with Agtos to create the best blasting machine for structural steel facility

- Utilizes adjustable air flow to pass through the heavy abrasive and remove any small particles

- Protected by manganese steel to keep entry points from wear

- Large blasting hotspot, not offered on any other single disk design turbine

- PeddiBlast turbines are strong power units which are highly cost effective due to fewer wear parts and a high abrasive flow

- Complete control of blasting process from control interface

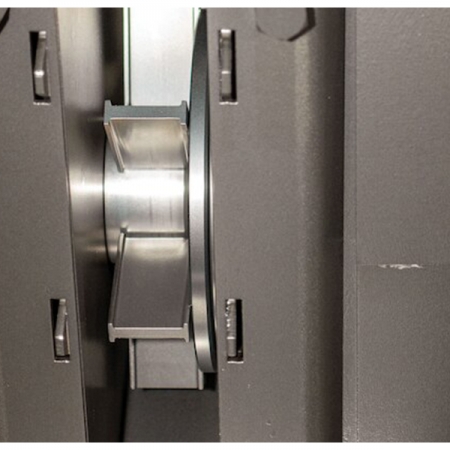

Powerful Blasting Turbine

Turbines on the PeddiBlast shot blast machine fall nothing short of strong, cost-effective power units. With blades built from tough manganese steel, the turbine housing is wear-resistant. This ensures the turbine will be able to operate for prolonged periods of time between services.

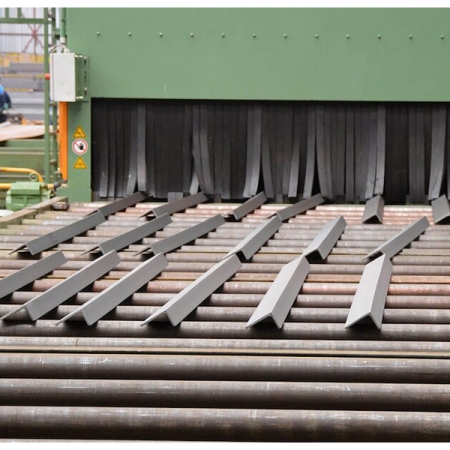

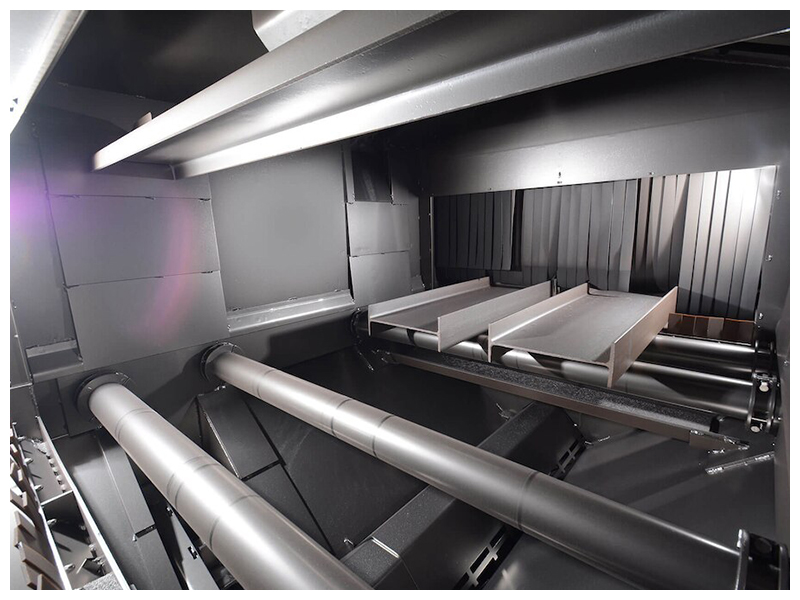

Protective Blast Chamber

Designed to give the turbines unobstructed paths to material being processed within, the chamber ensures successful blasting procedures every time. Abrasive is fed to the turbines via shell valves designed to regulate abrasive flow and limit abrasive consumption, ultimately reducing operating costs.

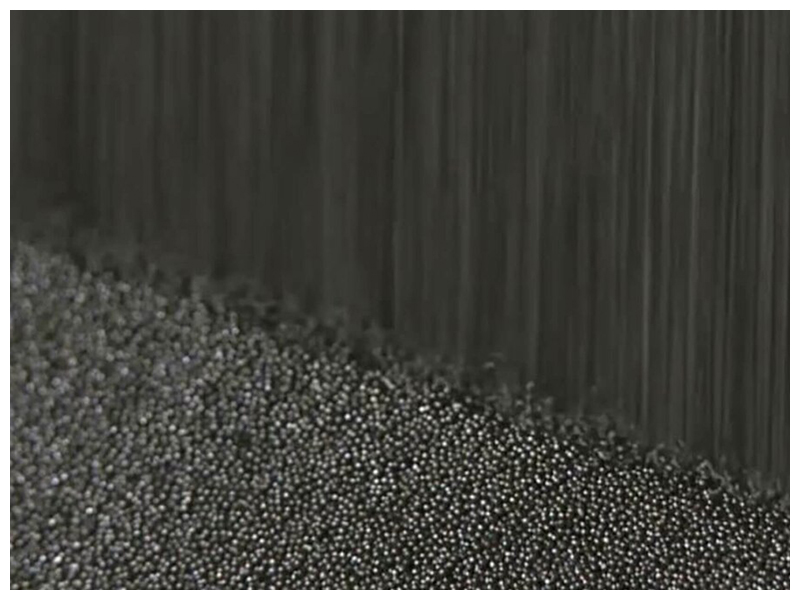

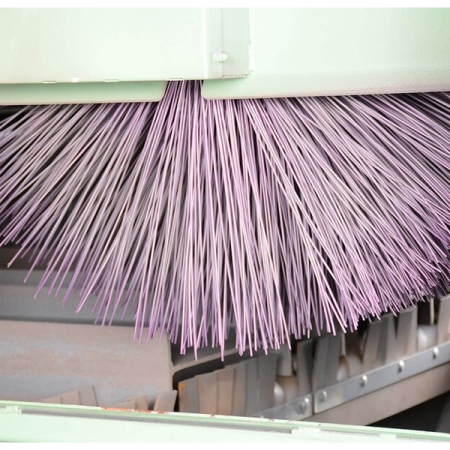

Abrasive Containment Curtains Keep Operators Safe

Each compartment within the PeddiBlast is outfitted with abrasive containment curtains designed to keep abrasive off the shop floor and keep operators safe from slips and falls.

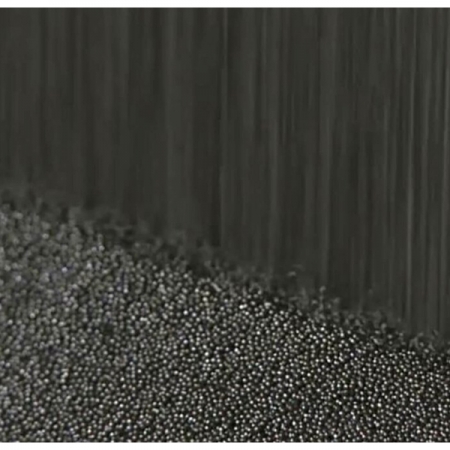

Bucket Elevator and Wind Separator

A bucket elevator effectively transports new and used abrasive up to the filters of the machine. Separating dust particles and worn out shot reduces the wear on the machine and results in a better blast quality.

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.