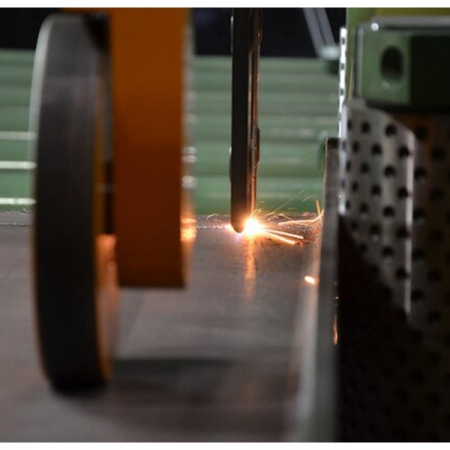

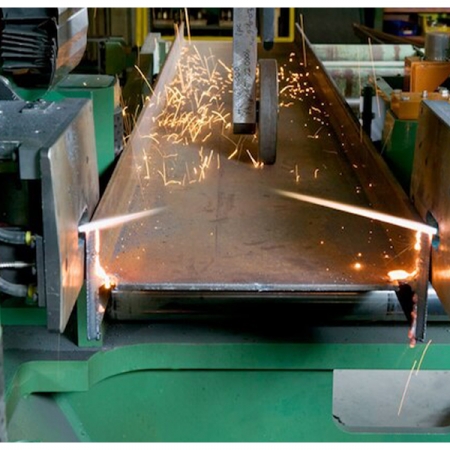

Burn Through the Thickest Flanges with Oxy-Fuel.

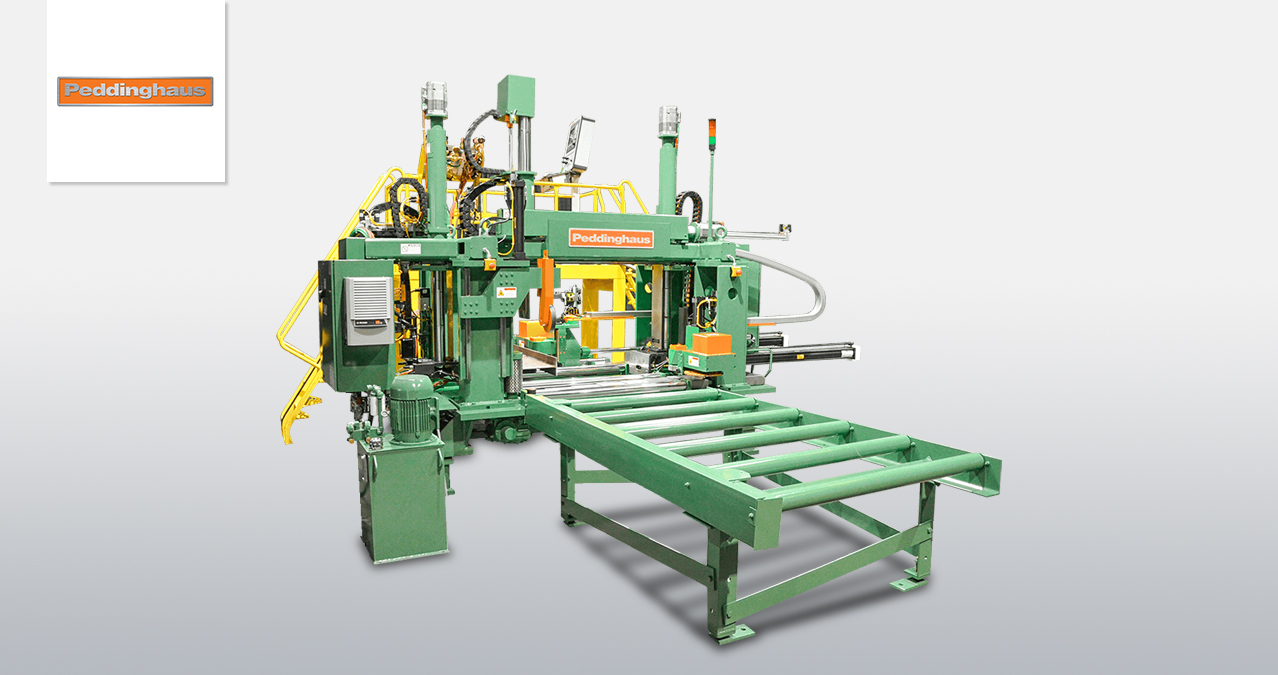

The Peddinghaus ABCM-1250 CNC Beam Coping Machine is ideally suited for mid-sized to larger fabricators, or fabricators that require high volumes of welded connections. The triple torch design of the ABCM-1250 CNC beam coping machine allows for the cutting of two flanges simultaneously. While flange thins are performed on both top and bottom flanges at the same time, weld prep is generated concurrently, keeping operating costs at a minimum. Without tedious torch probing processes, the ABCM-1250 oxy-fuel coper allows for more near flange cutting.

Why Peddinghaus ABCM-1250 CNC Beam Coping Machine?

- Ideal for the Automation of Common Copes: Shops that require web cutouts, flange penetrations, slotted tubes, block copes, “rat holes”, “dog bones”, and more find the ABCM performs each of these cuts flawlessly and at the lowest possible labor cost.

- Used as a Coper and a Miter Saw: Does your shop currently have a straight cut saw and just can’t justify the investment of a miter saw? Is your current cutting capacity overburdened? Combine your coping and miter cutting into one operation on the ABCM.

- Used for the Application of Split-T Sections: Structural split T’s are no problem with the Peddinghaus ABCM-1250 coping machine.

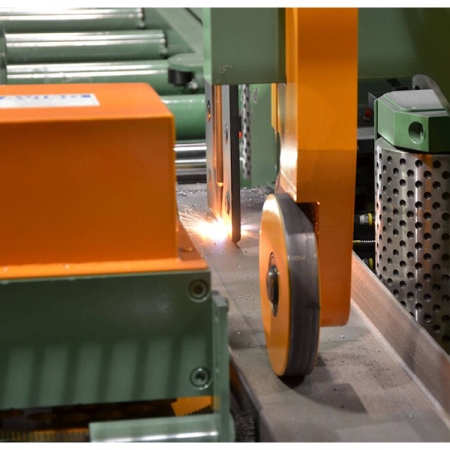

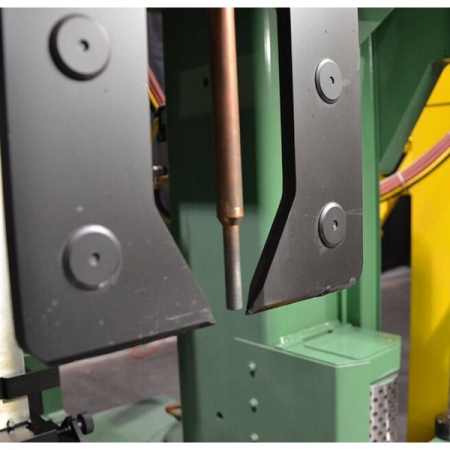

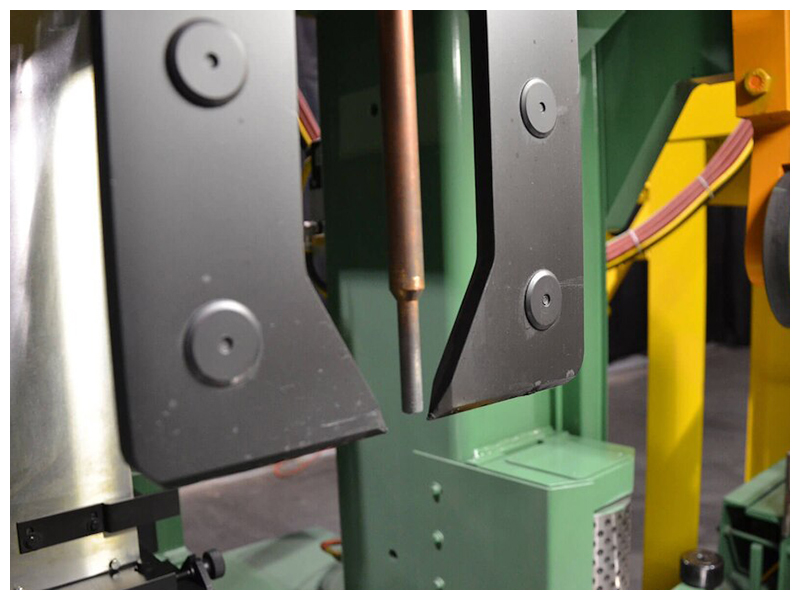

Triple the Processing Speed with Triple Torch Oxy-Fuel

Three torches for simultaneous oxy-fuel cutting create an unmatched combination of speed and efficiency. Capable of miter cutting and beveled weld preparation on the top and bottom flanges, the ABCM-1250 CNC beam coping machine also boasts automatic torch ignition.

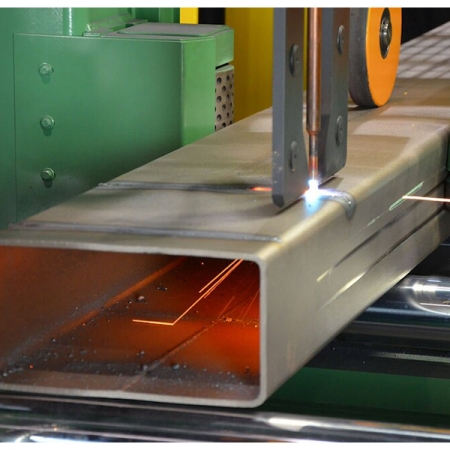

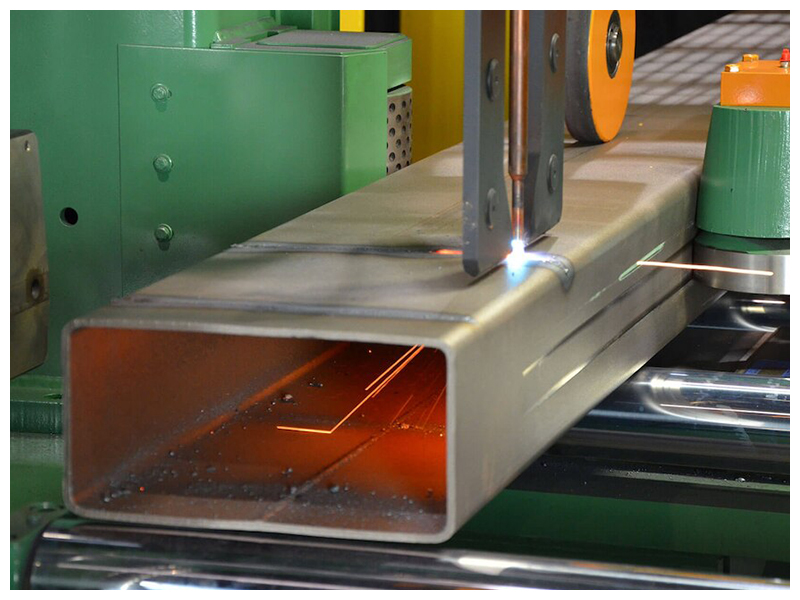

Bevel Cutting on Multiple Axes

Multiple axis positioning permits top and bottom flanges to be cut simultaneously. Flange beveling for weld prep is easily achieved with pivoting torches to the programmed miter position.

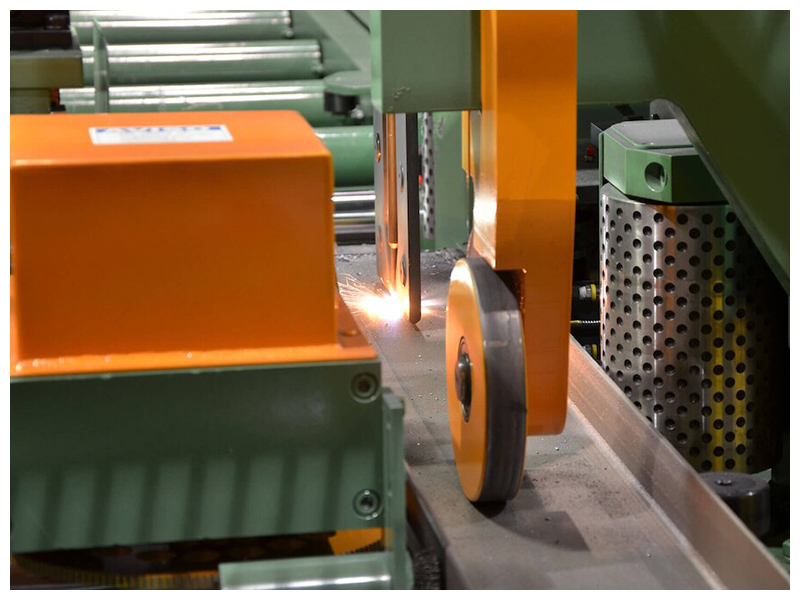

Nonstop Throughput with Roller Feed Measurement

Peddinghaus’ Roller Feed Measurement system exceeds the industry standard for roller measurement technology. Maintaining accurate measurements without any hesitation in production is crucial. Accuracy is not compromised even despite deviations in material.

Band Saw Integration for Extended Cutting Capabilities

Achieve miter and straight cutting on new levels with the ABCM-1250. Place in-line with any of Peddinghaus’ automatic sawing systems and separate beams in record time.

Dovetails, what’s the big deal?

Machinery SolutionsOnce you open the drawer and see the dovetail design, it elevates your product in the consumer’s eye. But why dovetail machine is right for my operation? When deciding to produce your own drawer boxes, a number of factors come into play when selecting the equipment required.

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.

Kingswood Cabinets. A true commitment to growth.

Case Study, Machinery Solutions, Service and SupportAkhurst is very proud of our involvement in the plant expansion of Kingswood Cabinets of Calgary, Alberta. Kingswood recently relocated to a new state-of-the-art manufacturing facility.