High performance brush sanding solution for sanding profiled doors & more

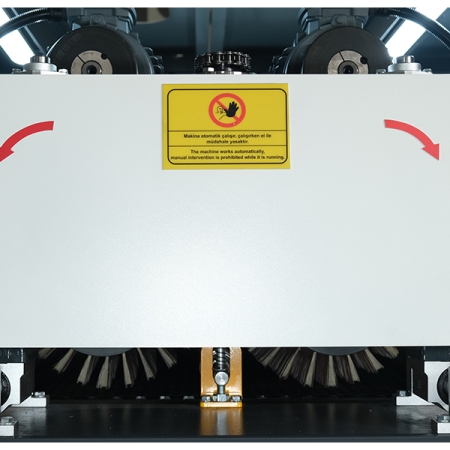

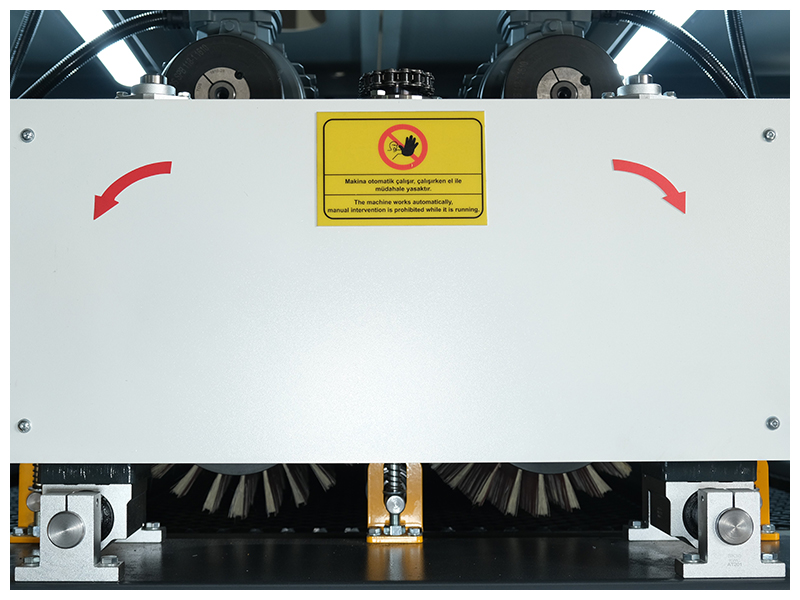

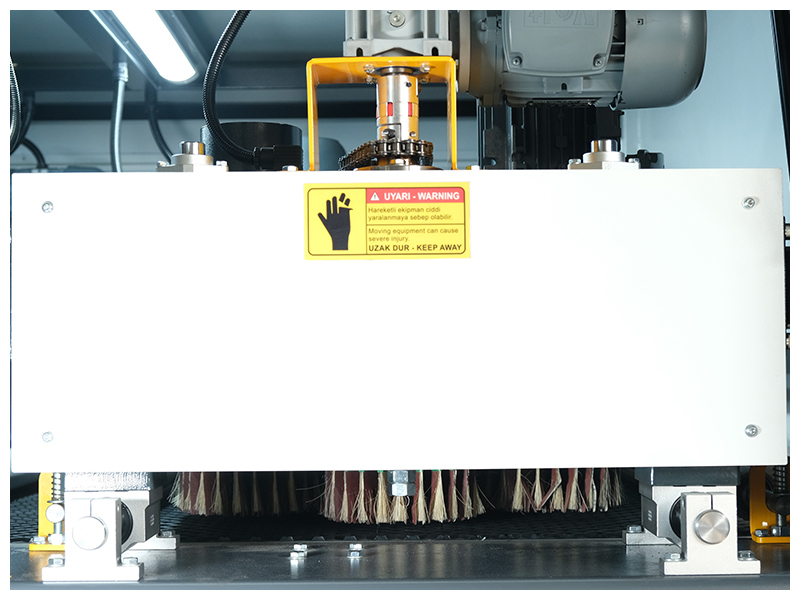

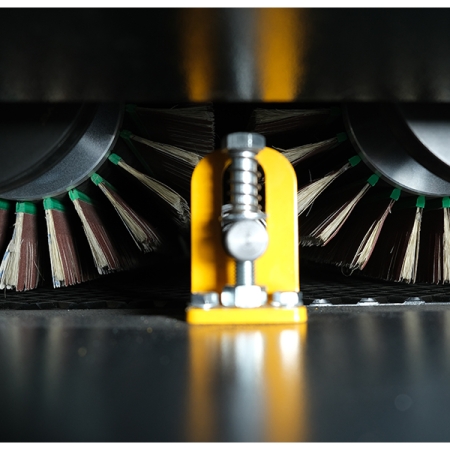

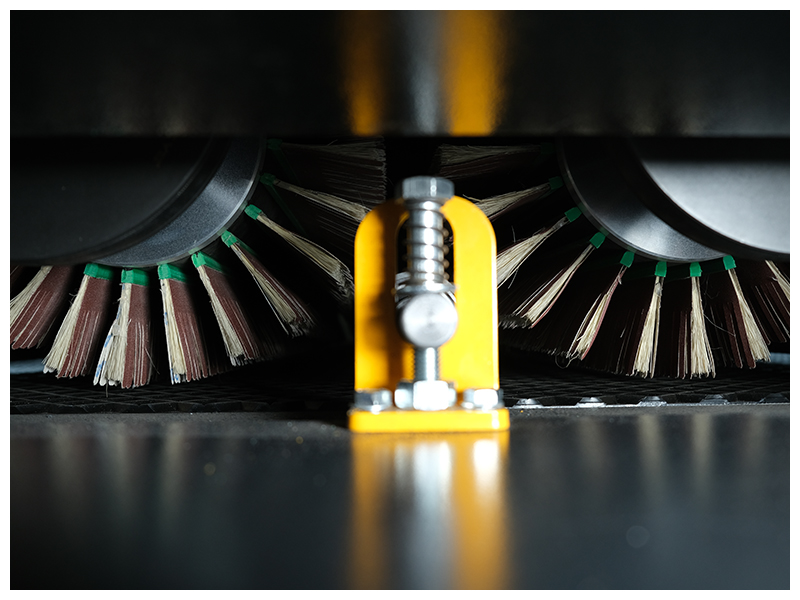

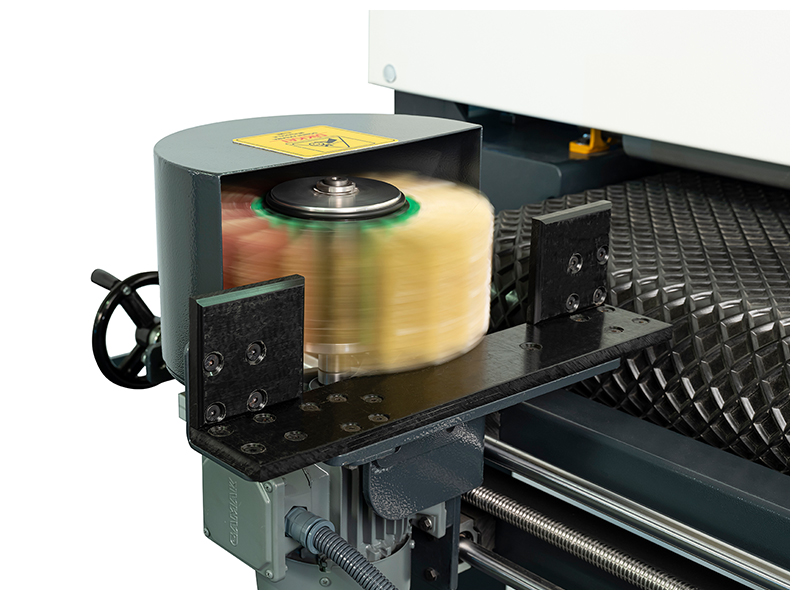

The Misirli SUPERSAND X uses a series of oscillating brush sanding units to sand both raw & finished profiled or flat wood components with incredible results. The SUPERSAND X is truly a versatile machine that can be used for white wood sanding, denibbing, or for sanding between finishing coats. It can be used to sand MDF or solid wood doors, furniture components, shutters, and more. The flap sanding strips are backed with a brush allowing it to penetrate down in to profiles where traditional flat sanding pads can not go. If you are looking to speed up your component sanding and improve on your quality look no further than the fully loaded SUPERSAND X brush sanding machine.

Why Misirli SUPERSAND X Brush Sanding Machine?

- Five sanding rows in total for a combination of cylindrical sanding, and disc sanding to ensure optimal results whether you are white wood sanding, denibbing, or sanding finished components between coats.

- User friendly touch screen interface with memory system (Smart Sanding System) allows the operator to fine tune programs while producing repeatable results

- Full control over the sanding head speed, oscillating, height, and rotation direction allow the operator to obtain the ideal sanding result.

- Comes with double sided abrasives for reduced setup time between sanding grits.

- Optional vacuum bed included for holding smaller workpieces during sanding operations

- Smaller footprint than the SUPERSAND XL

- Raw and Primer Sanding precision: 0.1 mm

- 5 rows of brush sanding units (2 Sections)

- 2 rows of cylinder sections (2 pieces.)

- 3 rows of disc section (5+6+5 pieces)

- Double-sided brush sanders (Motors can rotate in both directions.)

- 10” Touch Screen Control Panel – Memory System (Smart Sanding System)

- Full control over rotation speed, direction, and height

- Includes optional infeed and outfeed roller tables

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.