Production Double End Tenoner Series for Doors, Windows, and more.

The Cantek DET Series S-Type Double End Tenoners are the top of its line, constructed with robustness to meet the highest demands in various applications. They offer configurations with up to eight spindles (four on each side) and are available in widths ranging from 51” to 180”. These double end tenoners prove highly suitable for producing doors, furniture, windows, and more. The DET series can be tailored to your precise requirements, offering a diverse selection of processing units and features. You have the option to acquire the DET series as a standalone solution or as part of a production line, allowing for the automated processing of all four sides of a workpiece.

Why Cantek DET Series S-Type Double End Tenoners?

- Heavy duty base consisting of a double bed of welded and stress-relieved steel for superior vibration damping resulting in optimum cut quality and machine life

- Available in working widths from 51” to 180”, with motorized width adjustment

- Safe operation with sound/safety enclosures

- Fully customizable to suit your production requirements

- Configured with up to (8) spindles depending on your production needs

- Working configuration as below:

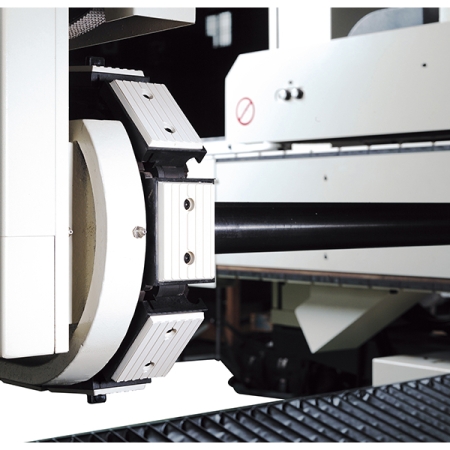

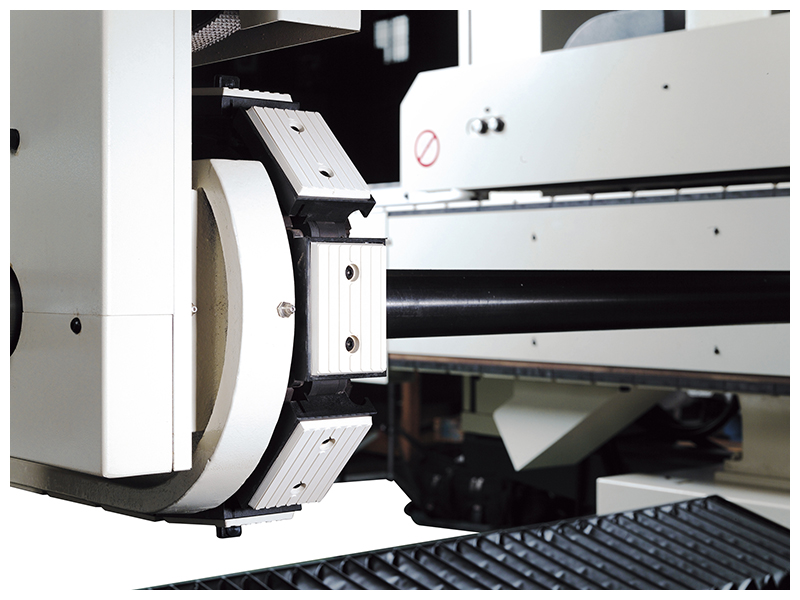

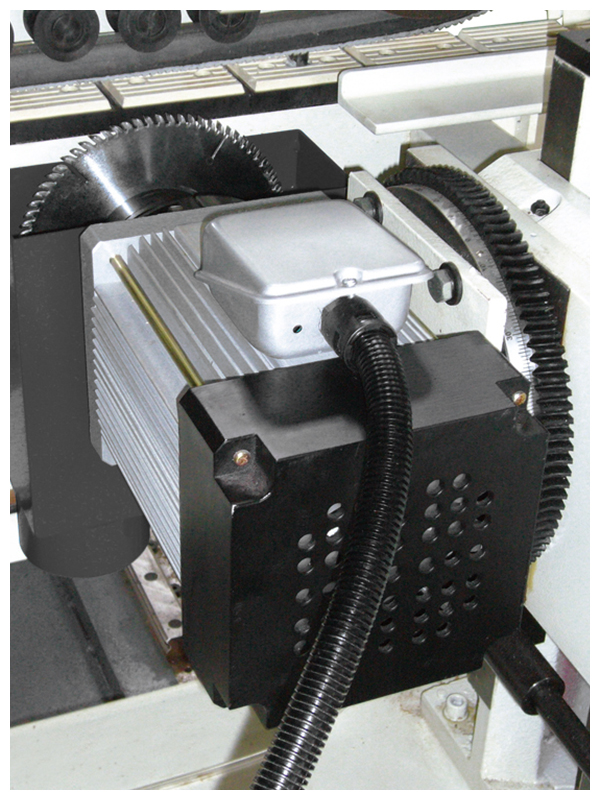

- Scoring saw (tiltable)

- Main cut-off saw (tiltable)

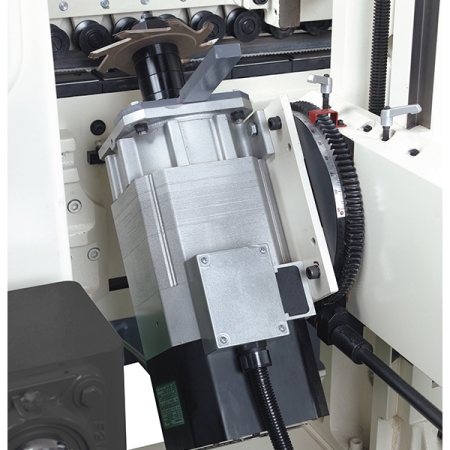

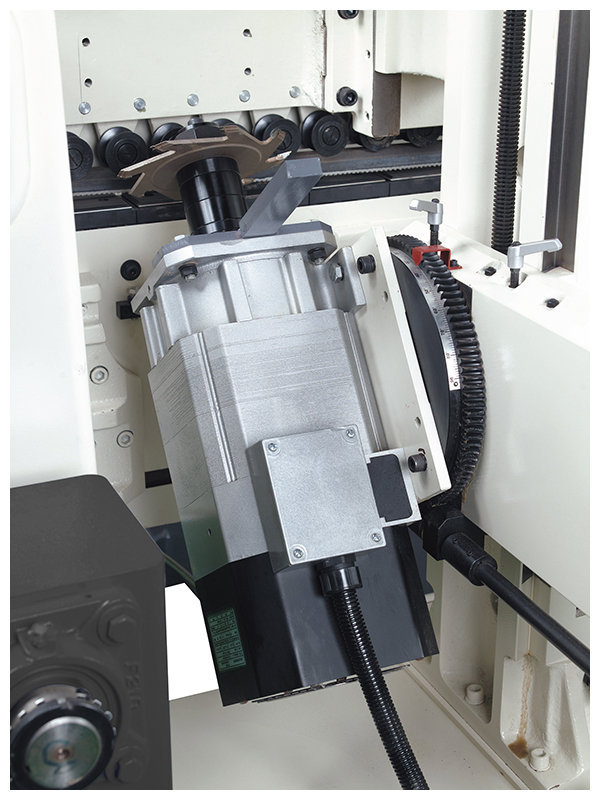

- Moulding station with jumping (not tiltable)

- Moulding station (tiltable)

- Tilting function ±90˚ on scoring, main saw, and moulding stations

- Non-through grooving function on 1st Moulding Units with jumping function

- Infeed and outfeed safety guards, as well as enclosed cabinet with safety interlocks on access doors

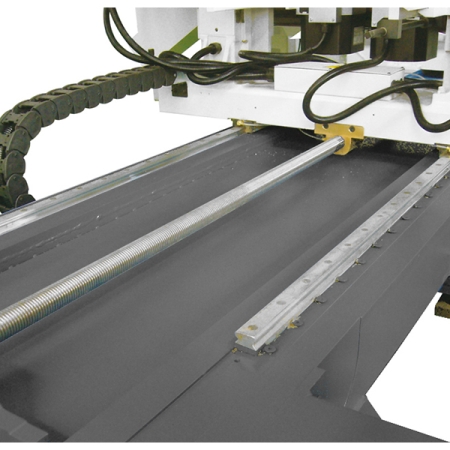

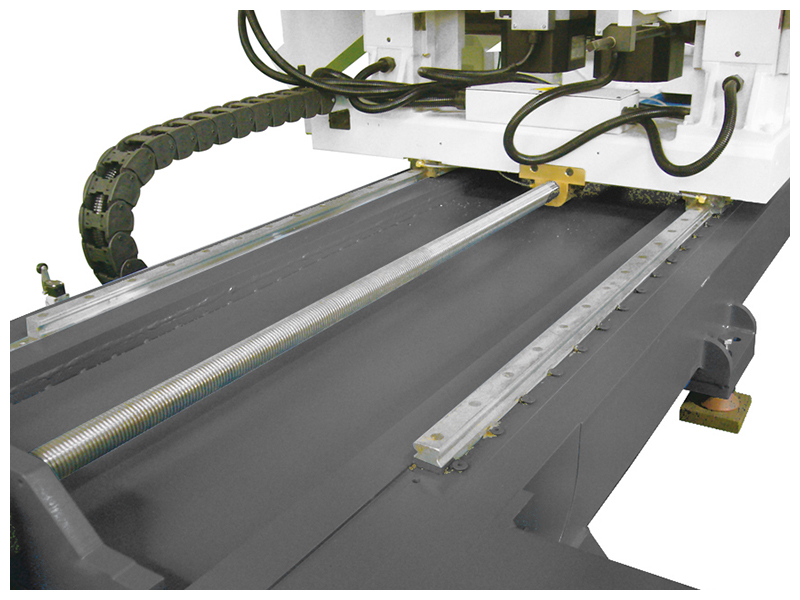

- Precision chain track assemblies with manually retractable stop dogs to ensure perfect “squareness”

- Adjustable infeed fence determines stock removal length

- Automatic braking of saw blades and moulding heads

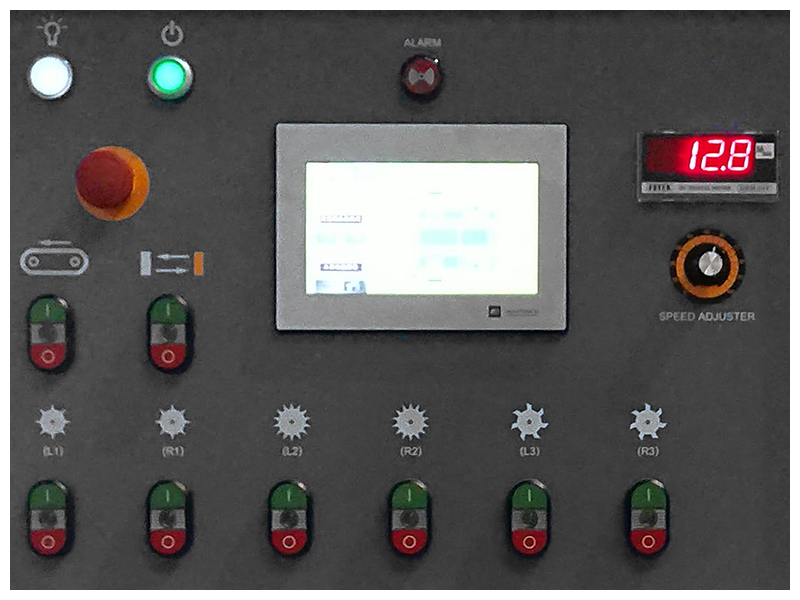

- Precision digital readouts for adjusting the workpieces accurately

- The feed conveyor is equipped with needle bearings to increase wear resistance.

- Choice of rubber or phenolic surfaces on chain pads

- The movable side is mounted on precision linear guideways to ensure accuracy & smooth movement

- Width is set through the tough screen combined with a PLC to ensure high positioning accuracy

- Schneider electrical components to CSA standard

- Mechanical digital readouts for accurate positioning of each working unit

- Optional HSK spindles for even faster changeovers