Whether it is furniture production, flooring manufacturing, or building materials; our double end tenoners can do it all.

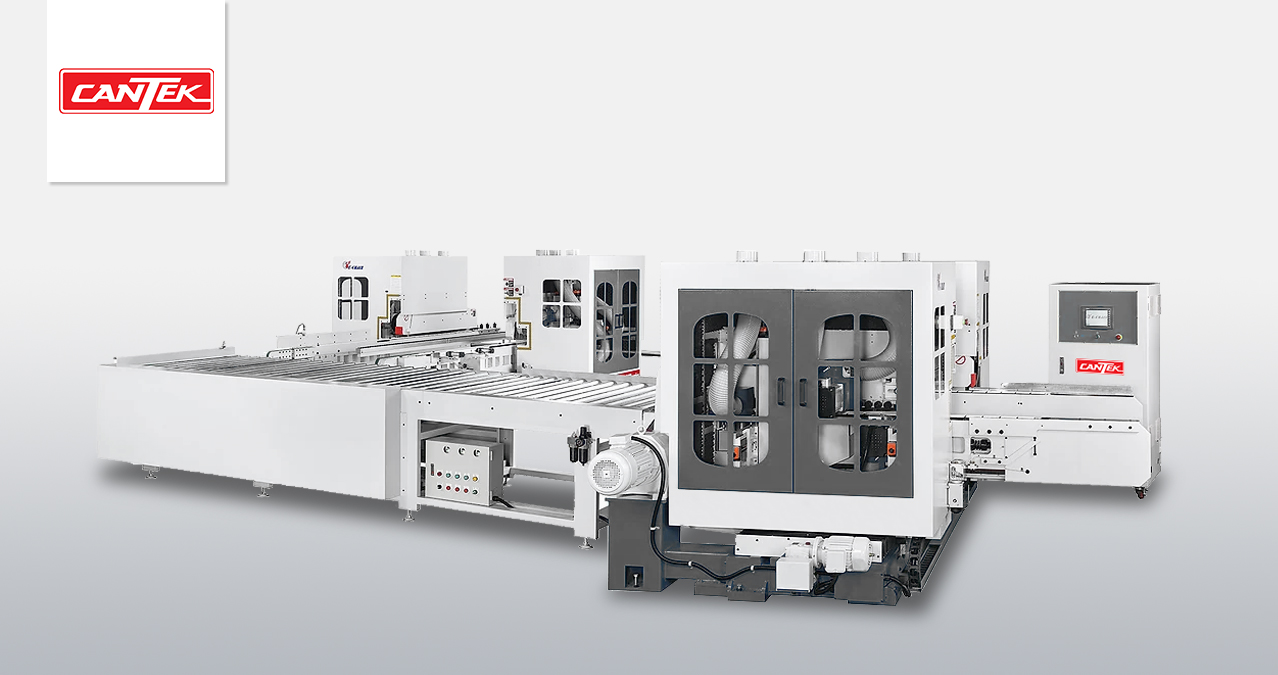

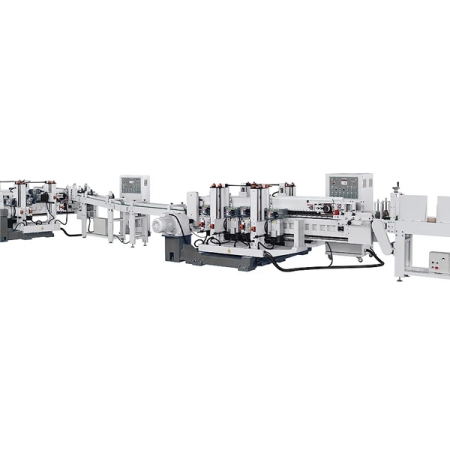

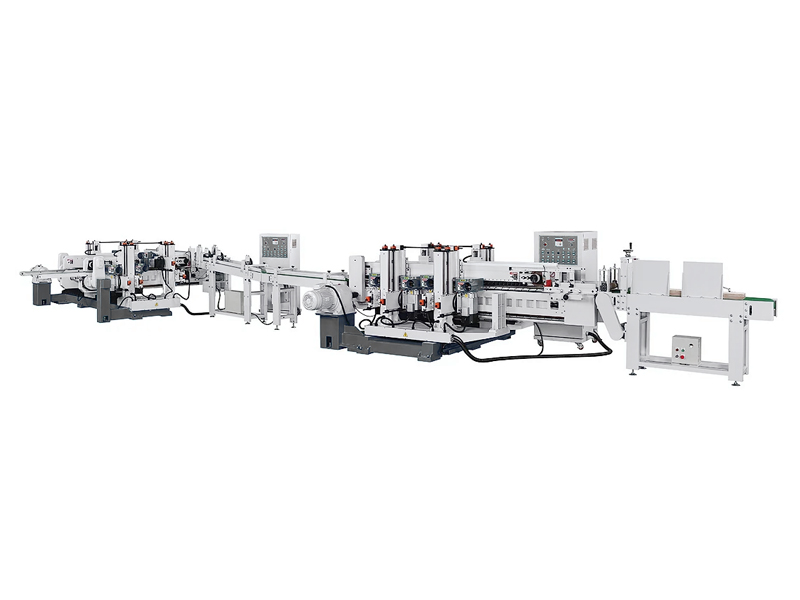

The Cantek DET FL-Type Full Line Double End Tenoners are designed to serve a variety of applications, ranging from furniture production to flooring manufacturing. We have a Double End Tenoner solution to meet your needs. This series is fully customizable to accommodate your warehouse and production requirements, offering a diverse selection of processing units and features. The available configurations are suitable for various applications, including doors, furniture, windows, flooring, and more. You can choose to purchase a machine in the DET series as a standalone solution or as part of a complete production line. These lines enable the automated processing of all four sides of a workpiece in a single assembly line.

Why Cantek DET FL-Type Full Line Double End Tenoner?

- 90° cross-transfer line – for furniture and building materials

- Fully Automatic line – for flooring

- Automatic double end curved profile sander – for cabinets doors

- Drilling & Milling Machine

- Straight line with clamp turner with automatic vacuum loading and unloading

- Straight line with clamp turner – for furniture and building materials

- 2 stage – for furniture and building materials

Enjoy the flexibility of selecting from a wide selection of working units to choose from, as any Cantek Double End Tenoner can be custom-built with machine frames of different sizes to house up to fourteen (14) working units, such as…

- Fixed Scoring and Main Saw Systems

- Jump Scoring Saw System

- Tiltable Saw System

- Jump Moulding System (High-Frequency Motor)

- Tiltable Moulding System (High-Frequency Motor)

- Moulding System (Belt Driven Spindle)

- Top and Bottom Tenoning Systems

- Top and Bottom Chamfering Systems

- Copy (Floating) Top and Bottom Chamfering Systems

- Boring System (At Infeed)

- Belt Sanding System (Standard-Type)

- Belt Sanding System (Wide-Type)

- Automatic Tool Changer

- Spindle Sanding System (With Auto-Compensation Function)

- Central Panel Splitting System

- Central Grooving System