Elevate your craft with one machine that allows you to do it all.

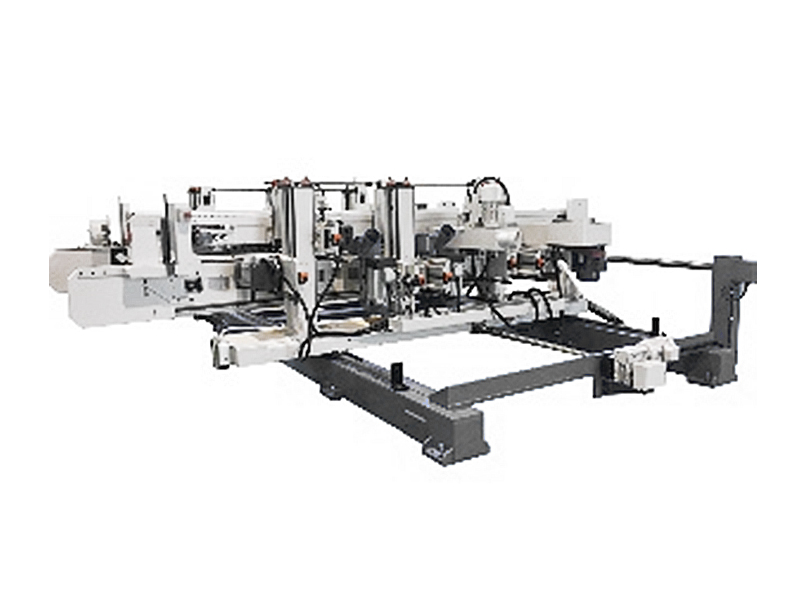

The Cantek DET AB-Type Extended Double End Tenoner is a modified machine that features an assembled-type base design, utilizing a wide base that allows for an increase in the housing capacity expanding the functionality for up to 14 working units (7 per side). With a wide range of working units to choose from, including, saw units, profile moulding units, tenoning units, profile sanding units, top and bottom chamfering units, drilling units, etc., every Double End Tenoner is fully customizable to suit highly specific machining requirements. HSK 63F spindles and NC positioning via servo with programmable recipe inputs can be added for quick tooling changeover to facilitate efficient small-batch manufacturing. Whether you need a standalone unit or part of a comprehensive production line, we offer tailored solutions to suit your needs.

Why Cantek DET AB-Type Extended Double End Tenoner?

- Enjoy the flexibility of selecting from a wide selection of working units to choose from, this type of Cantek Double End Tenoner can be custom-built with a wide machine frame and different sizes to house up to fourteen (14) working units, for example…

- Sample Working Configuration:

- Scoring Saw System

- Main Saw System

- 1st Moulding System

- 2nd Moulding System

- Belt Sanding System (Standard-Type)

- 1st Spindle Sanding System

- 2nd Spindle Sanding System

More Working Unit Options:

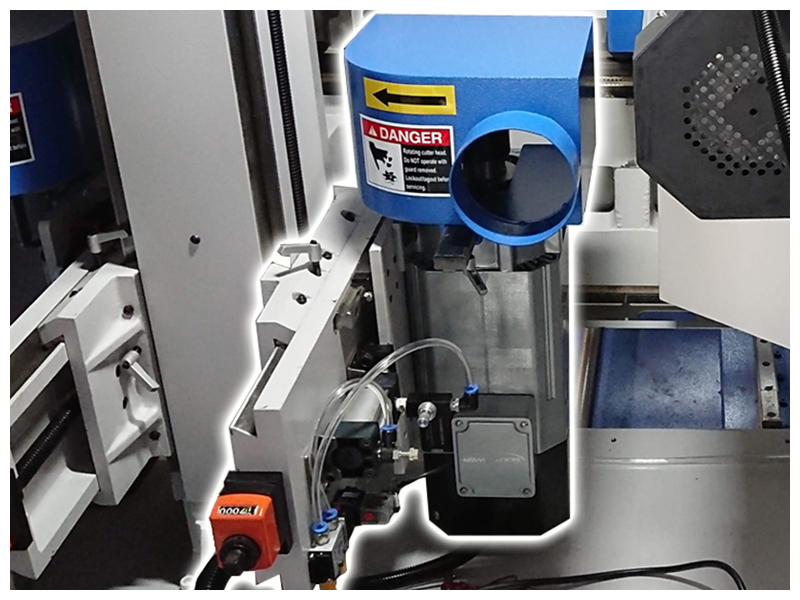

- Fixed Scoring and Main Saw Systems

- Jump Scoring Saw System

- Tiltable Saw System

- Jump Moulding System (High-Frequency Motor)

- Tiltable Moulding System (High-Frequency Motor)

- Moulding System (Belt Driven Spindle)

- Moulding System (HSK 63F Motor)

- Top and Bottom Tenoning Systems

- Top and Bottom Chamfering Systems

- Copy (Floating) Top and Bottom Chamfering Systems

- Boring System (At Infeed)

- Belt Sanding System (Standard-Type)

- Belt Sanding System (Wide-Type)

- Automatic Tool Changer

- Spindle Sanding System (With Auto-Compensation Function)

- Central Panel Splitting System

- Central Grooving System

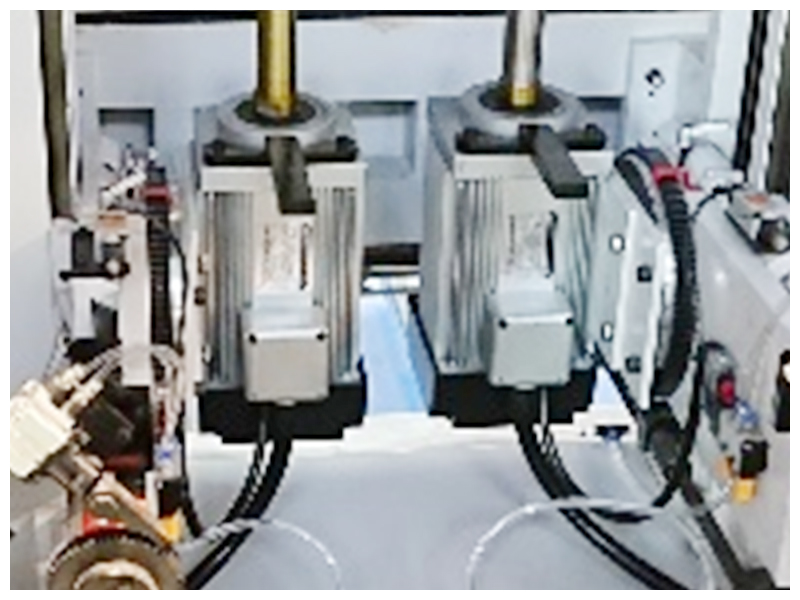

Fully automatic functions to significantly reduce operator calibration time when switching from one job to the next include…

- NC servo positioning on the movable side of double end tenoner

- NC servo positions on top pressure hold downs

- NC servo positioning on working units (horizontal and vertical axes)

- NC servo positioning on infeed fence

- Automatic dogs

User-friendly HMI that offers upgrades for recipe storage/upload of working parameters for up to 100 sets up tooling; accessed via batch number input, barcode scanning or Microsoft Excel Spreadsheet (via MX Sheet)