Versatile range of vertical working and storage stillages for modular offsite construction projects.

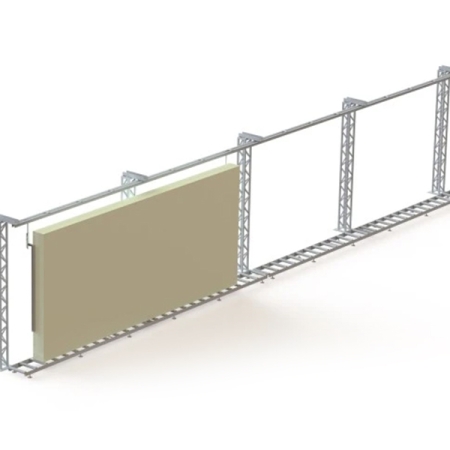

The MBA X-Vertical Stillage for Modular Offsite Construction is a complete vertical workstation designed for working on or storing completed wall panels. The walls are placed on roller tracks for convenient mobility to easily install windows, doors, electrical, and/or cladding materials. The wall panel is firmly secured using a guide rail and roller conveyor, featuring manually adjustable locking handles for securely positioning the panel. The single-sided system facilitates work on both sides of the wall panel, while the double-sided system permits work on only one side but offers significantly greater storage capacity. It incorporates a distinctive panel securing device that facilitates loading and unloading from either the end or the side of the system. Additionally, for every 10 meters (32 feet) of vertical line, two support arms are provided for one panel.

Why the MBA X-Vertical Stillage?

- Panel clamping at the base of the wall panel

- Rollers for easy movement of the workpiece

- Design of single-sided system allows for working on both sides of the panel

- Stations can be used for the fitting of windows, doors, electrical, and/or cladding

Metric |

Inch |

|

Single-sided length |

10 m – 20 m |

33 ft – 66 ft |

Single-sided length |

21 m – 30 m |

69 ft – 98 ft |

Single-sided length |

Above 31 m |

Above 102 ft |

Double-sided length |

10 m – 20 m |

33 ft – 66 ft |

Double-sided length |

21 m – 30 m |

69 ft – 98 ft |

Double-sided length |

Above 31 m |

Above 102 ft |

Dovetails, what’s the big deal?

Machinery SolutionsOnce you open the drawer and see the dovetail design, it elevates your product in the consumer’s eye. But why dovetail machine is right for my operation? When deciding to produce your own drawer boxes, a number of factors come into play when selecting the equipment required.

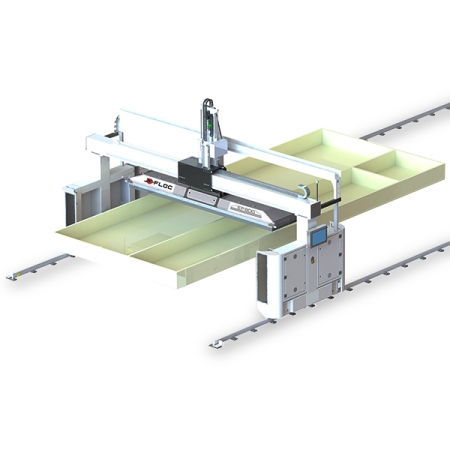

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.

Kingswood Cabinets. A true commitment to growth.

Case Study, Machinery Solutions, Service and SupportAkhurst is very proud of our involvement in the plant expansion of Kingswood Cabinets of Calgary, Alberta. Kingswood recently relocated to a new state-of-the-art manufacturing facility.