The one stop shop for wall panel manufacturing and offsite construction.

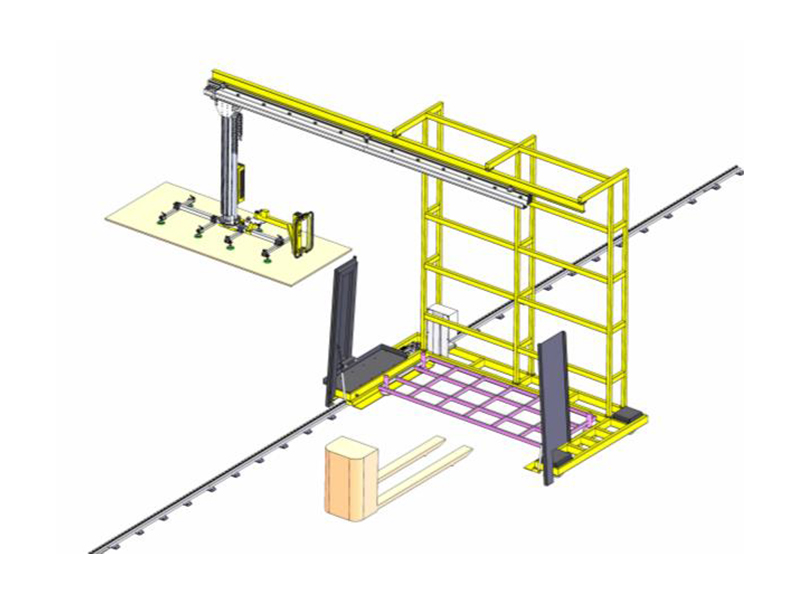

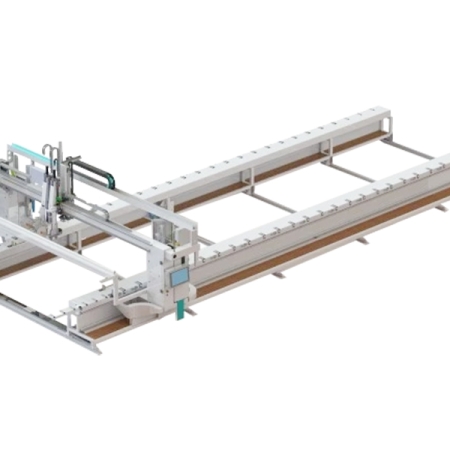

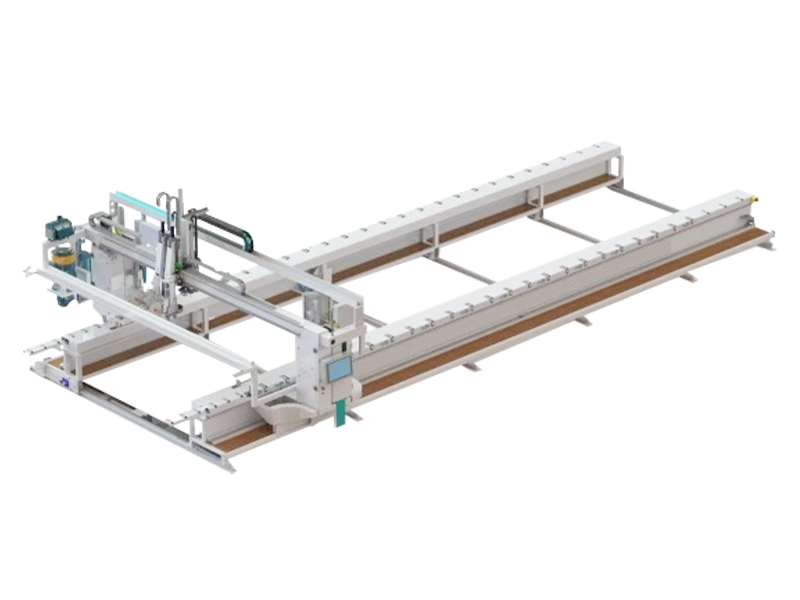

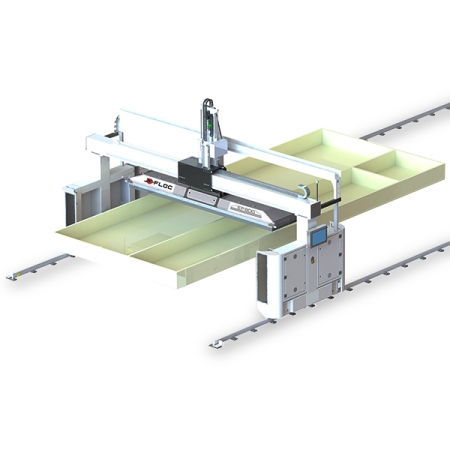

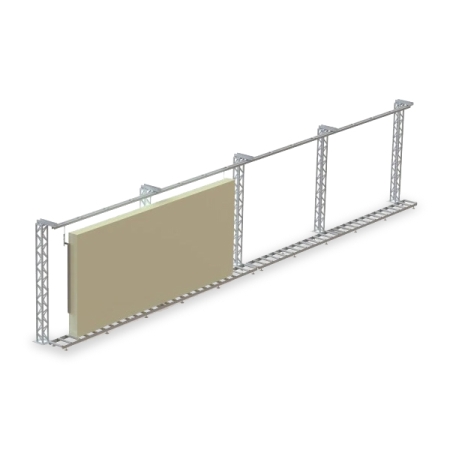

The MBA X-Combi Complete Assembly Machine For Timber Frame Construction is a complete working station for the production of timber frame wall panels, catering to the offsite construction and modular building construction industry. The machine integrates the functionalities of both a framing station and a nailing bridge into a single unit, occupying less than half the floor space and requiring only one person to operate. From the first nail in the initial stud to the last nail in the cladding, the X-Combi securely clamps each panel, ensuring precise and efficient manufacturing of even the most intricate panels.

Why the MBA X-Combi?

- Full control with two 19” touchscreens

- Interactive display of operation being performed

- Automatic download from drawing software

- Heavy duty tables with one fixed side and one moving side

- Motorized table opening with automatic brake locking

- Independent retractable clamping system, for the complete access of nail guns along the top and bottom rails, to enable square and accurate clamping of the panel

- 90-degree squaring corner blocks with pneumatic retraction to enable the panel to move to the next position when finished

- A complete working station for the production of timber frame construction walls including the following functions:

- Framing of the wall

- Application of cladding

- Nailing or stapling of cladding

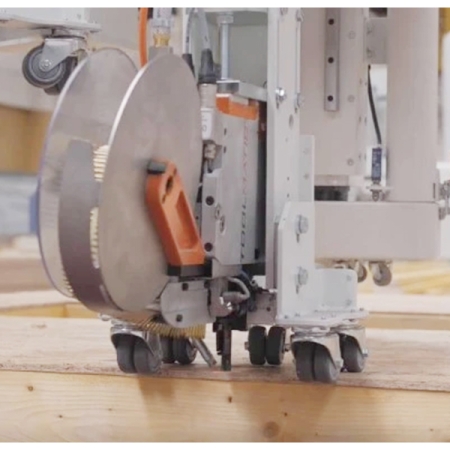

- Drilling and routing of openings and overhangs

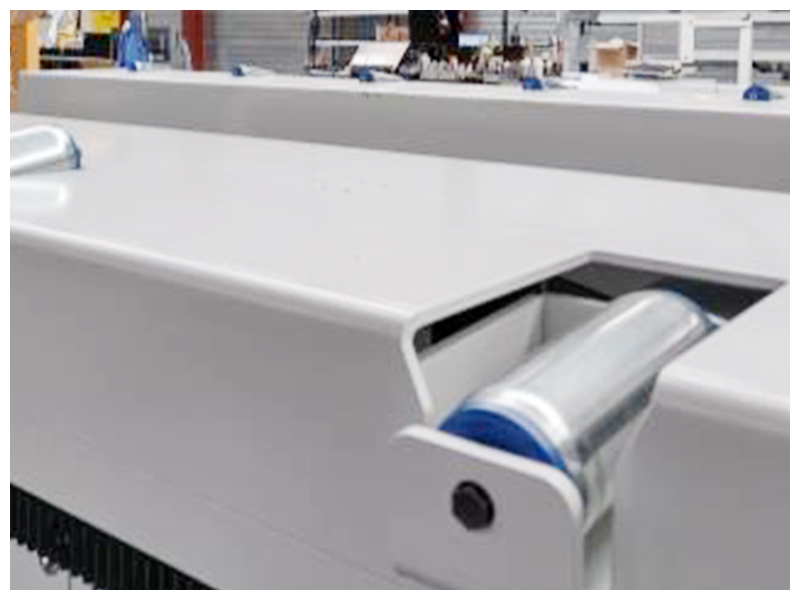

- Application of breather paper

- Nailing of battens

- Gluing of sheeting material to frames

- Motorised table opening with automatic brake locking

- Independent retractable clamping system, for the complete access of nail guns along top and bottom rails, to enable square and accurate clamping of the panel

- Framing tools driven to the required position via a servo drive motor, with heights controlled by software

- Bridge mounted with nailing / stapling tool as standard. Options for other tools to be mounted

- Full integration with major software packages including Sema, Dietrich;s, HsbSoft, CADWORKS, Gang Nail, DDS, Mitek.& Inventor

- Batten application system with guide to ensure they battens are kept straight before nailing including batten storage area

- Pneumatic lifting rollers to assist the manually transporting of the finished panel to next position.

Akhurst Machinery Group announces strategic partnership to aid North American housing crisis.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the North American machinery industry, is pleased to announce a strategic partnership with Modular Building Automation (MBA), a Dutch company specializing in machinery for prefabricated homes, modular buildings, and offsite construction solutions. MBA, a joint venture of the renowned companies J.J. Smith in the UK and Ireland and H&M headquartered in the Netherlands, is involved in the design, manufacturing, distribution, and worldwide sales of MBA equipment.

Akhurst Machinery Group announces strategic partnership with Stromab.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the machinery industry, proudly announces a strategic partnership with Stromab SPA, an Italian manufacturer of innovative crosscutting solutions. This collaboration signifies a major commitment by both companies to bring cutting-edge technology and comprehensive solutions to the North American market. Akhurst Machinery Group, the parent company behind the well-known brands of Cantek and Leadermac USA, will leverage Stromab SPA’s expertise in crosscutting solutions to enhance its offerings in North America.

Woodworking Technology Days 2023 is just around the corner.

Corporate, Machinery Solutions, Trade ShowsVisit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.