Versatile range of vertical working and storage stillages for modular offsite construction projects.

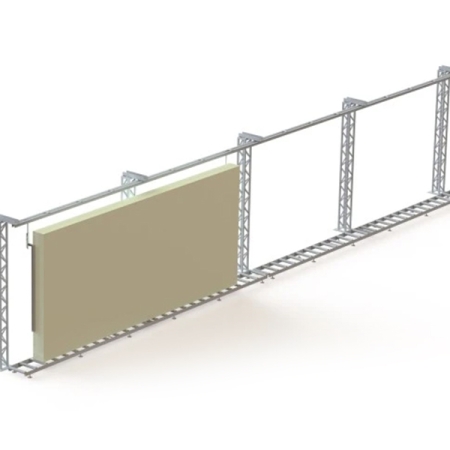

The MBA X-Vertical Stillage for Modular Offsite Construction is a complete vertical workstation designed for working on or storing completed wall panels. The walls are placed on roller tracks for convenient mobility to easily install windows, doors, electrical, and/or cladding materials. The wall panel is firmly secured using a guide rail and roller conveyor, featuring manually adjustable locking handles for securely positioning the panel. The single-sided system facilitates work on both sides of the wall panel, while the double-sided system permits work on only one side but offers significantly greater storage capacity. It incorporates a distinctive panel securing device that facilitates loading and unloading from either the end or the side of the system. Additionally, for every 10 meters (32 feet) of vertical line, two support arms are provided for one panel.

Why the MBA X-Vertical Stillage?

- Panel clamping at the base of the wall panel

- Rollers for easy movement of the workpiece

- Design of single-sided system allows for working on both sides of the panel

- Stations can be used for the fitting of windows, doors, electrical, and/or cladding

Metric |

Inch |

|

Single-sided length |

10 m – 20 m |

33 ft – 66 ft |

Single-sided length |

21 m – 30 m |

69 ft – 98 ft |

Single-sided length |

Above 31 m |

Above 102 ft |

Double-sided length |

10 m – 20 m |

33 ft – 66 ft |

Double-sided length |

21 m – 30 m |

69 ft – 98 ft |

Double-sided length |

Above 31 m |

Above 102 ft |

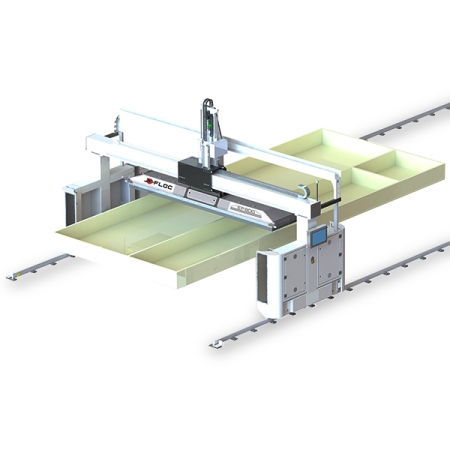

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.