Versatile boring machine for a wide range of drilling operations.

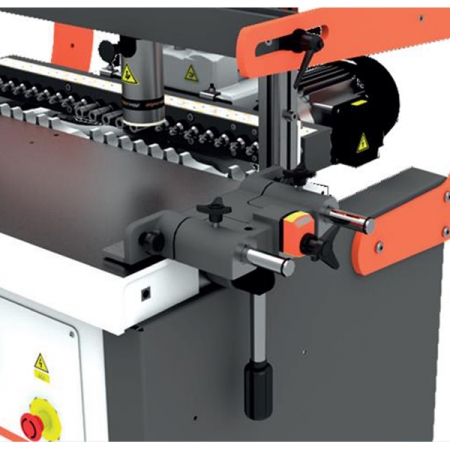

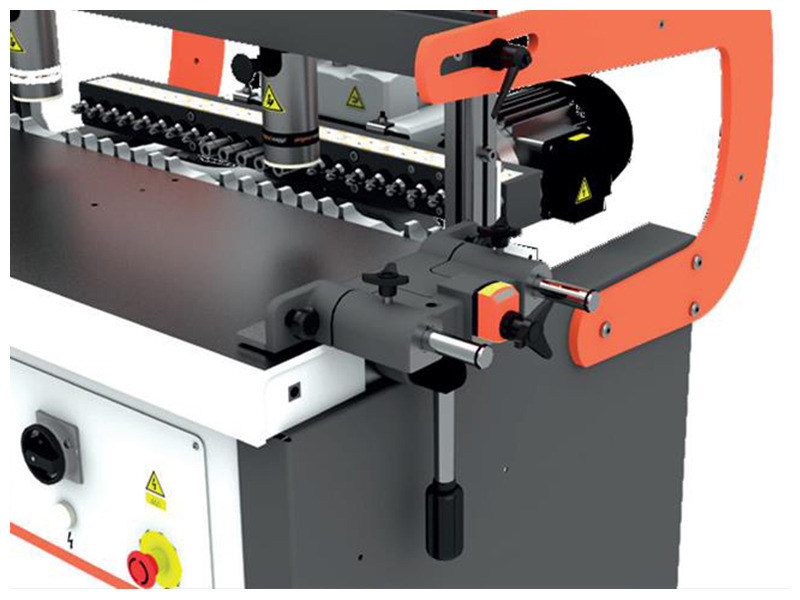

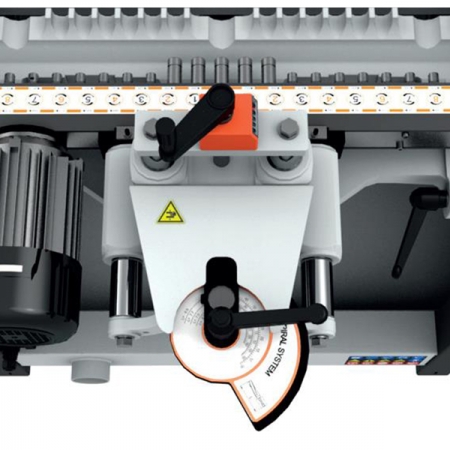

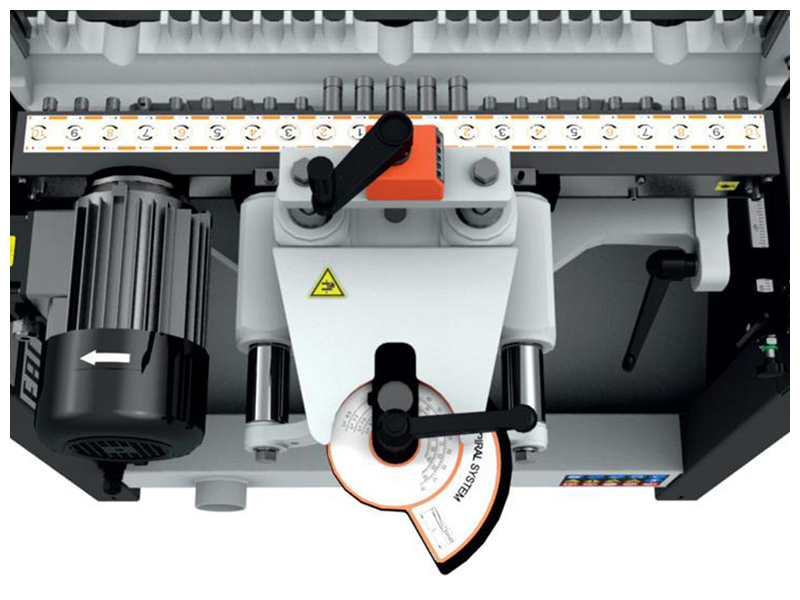

The Maggi System 23 Construction Boring Machine is a versatile boring machine for the construction of cabinets and case goods performing the functions of line boring, construction drilling, end drilling for dowels and more. It is equipped with a single row of 23 spindles spaced on 32mm. The quick-change chucks allow for quick boring pattern setup. The patented spiral depth adjustment system allows for easy and quick setup for the boring depth according to the various drill lengths. The boring head is rotated from a vertical to horizontal position with a simple pneumatic cylinder and can be set on any angle from 0° to 90°. Equipped with a 3-meter back fence and flip stops and right and left fold away side fences fitted with mechanical readouts for accurate positioning, the System 23 truly can do it all.

Why Maggi System 23 Construction Boring Machine?

- Patented spiral system for extremely fast and accurate boring depth adjustment according to different drill bit lengths

- Pneumatic head rotation can be adjusted anywhere from 0° ~ 90°

- Quick and easy positioning thanks to numeric counters having first-spindle axis as the main reference point

- Powerful 2HP boring head for all of your drilling requirements

- 3000mm back fence with (4) flip stops for accurate panel positioning

- Equipped with (23) quick change chucks to allow for fast boring pattern setup and quick boring bit changeover for various operations

- (2) material clamps safety clamps

- Powerful 2HP drilling motor

- Patented spiral system for fast and accurate boring depth adjustment

- Pneumatic drill beam rotation from 0 ~ 90° with reference stops

- Adjustable side fences with mechanical digital readouts for fast and accurate adustment

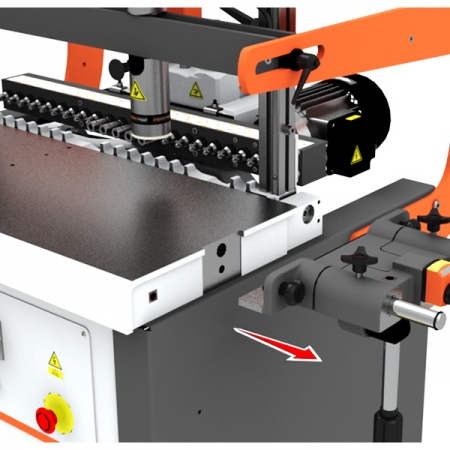

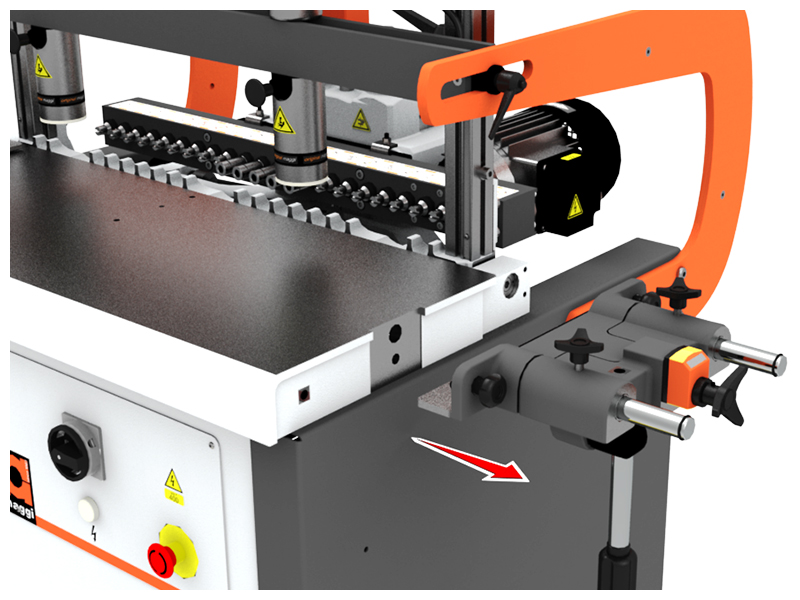

- Accurate positioning of the boring unit to the table with digital readout

- Cast iron table which is precision ground

- Foot actuation for clamping and drilling cycle

OPTIONAL EQUIPMENT INCLUDED IN STOCK CONFIGURATION:

- (1) additional pneumatic material clamp

- (1) stop reference pin for continuous line boring

- Set of reference fences for moulding at 45 & 90 degrees

Dovetails, what’s the big deal?

Machinery SolutionsOnce you open the drawer and see the dovetail design, it elevates your product in the consumer’s eye. But why dovetail machine is right for my operation? When deciding to produce your own drawer boxes, a number of factors come into play when selecting the equipment required.

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.

Kingswood Cabinets. A true commitment to growth.

Case Study, Machinery Solutions, Service and SupportAkhurst is very proud of our involvement in the plant expansion of Kingswood Cabinets of Calgary, Alberta. Kingswood recently relocated to a new state-of-the-art manufacturing facility.