Versatile boring machine for a wide range of drilling operations.

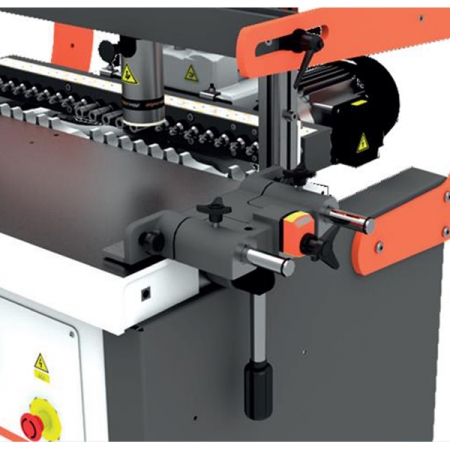

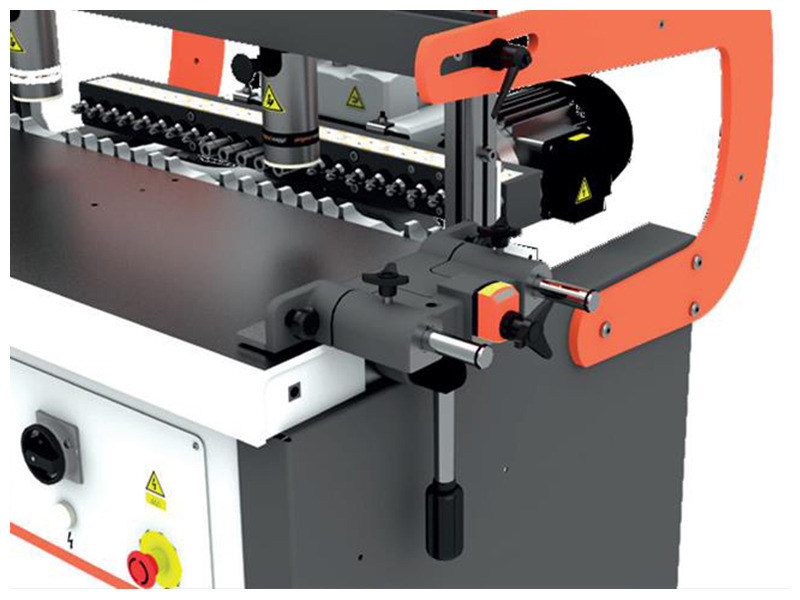

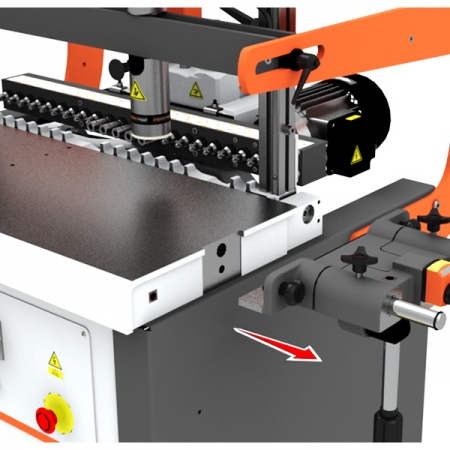

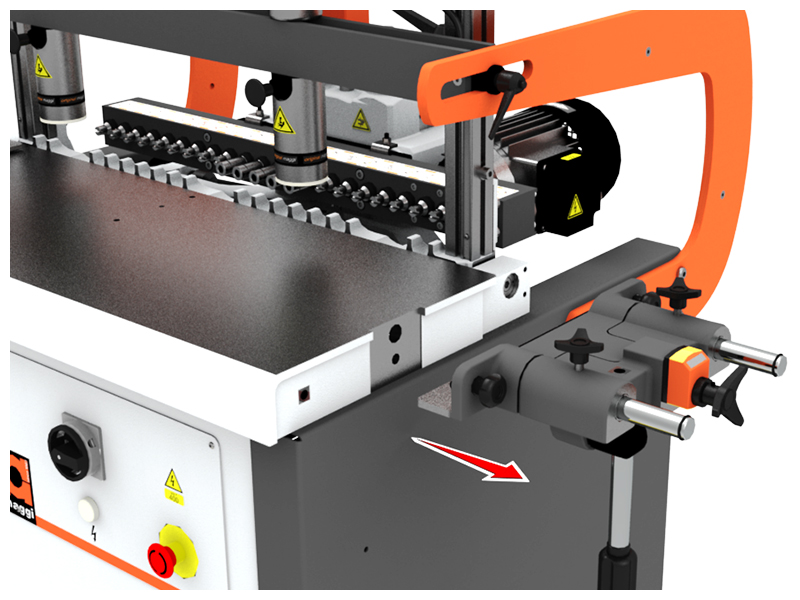

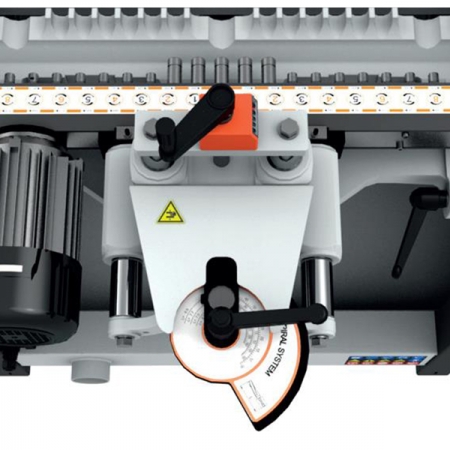

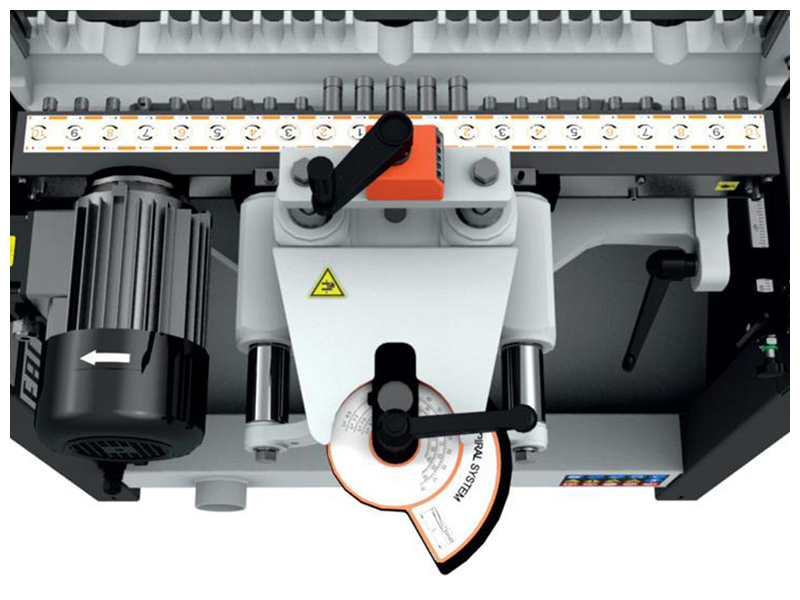

The Maggi System 23 Construction Boring Machine is a versatile boring machine for the construction of cabinets and case goods performing the functions of line boring, construction drilling, end drilling for dowels and more. It is equipped with a single row of 23 spindles spaced on 32mm. The quick-change chucks allow for quick boring pattern setup. The patented spiral depth adjustment system allows for easy and quick setup for the boring depth according to the various drill lengths. The boring head is rotated from a vertical to horizontal position with a simple pneumatic cylinder and can be set on any angle from 0° to 90°. Equipped with a 3-meter back fence and flip stops and right and left fold away side fences fitted with mechanical readouts for accurate positioning, the System 23 truly can do it all.

Why Maggi System 23 Construction Boring Machine?

- Patented spiral system for extremely fast and accurate boring depth adjustment according to different drill bit lengths

- Pneumatic head rotation can be adjusted anywhere from 0° ~ 90°

- Quick and easy positioning thanks to numeric counters having first-spindle axis as the main reference point

- Powerful 2HP boring head for all of your drilling requirements

- 3000mm back fence with (4) flip stops for accurate panel positioning

- Equipped with (23) quick change chucks to allow for fast boring pattern setup and quick boring bit changeover for various operations

- (2) material clamps safety clamps

- Powerful 2HP drilling motor

- Patented spiral system for fast and accurate boring depth adjustment

- Pneumatic drill beam rotation from 0 ~ 90° with reference stops

- Adjustable side fences with mechanical digital readouts for fast and accurate adustment

- Accurate positioning of the boring unit to the table with digital readout

- Cast iron table which is precision ground

- Foot actuation for clamping and drilling cycle

OPTIONAL EQUIPMENT INCLUDED IN STOCK CONFIGURATION:

- (1) additional pneumatic material clamp

- (1) stop reference pin for continuous line boring

- Set of reference fences for moulding at 45 & 90 degrees

Akhurst Machinery Group Announces Strategic Partnership to Aid North American Housing Crisis

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the North American machinery industry, is pleased to announce a strategic partnership with Modular Building Automation (MBA), a Dutch company specializing in machinery for prefabricated homes, modular buildings, and offsite construction solutions. MBA, a joint venture of the renowned companies J.J. Smith in the UK and Ireland and H&M headquartered in the Netherlands, is involved in the design, manufacturing, distribution, and worldwide sales of MBA equipment.

Akhurst Machinery Group announces strategic partnership with Stromab.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the machinery industry, proudly announces a strategic partnership with Stromab SPA, an Italian manufacturer of innovative crosscutting solutions. This collaboration signifies a major commitment by both companies to bring cutting-edge technology and comprehensive solutions to the North American market. Akhurst Machinery Group, the parent company behind the well-known brands of Cantek and Leadermac USA, will leverage Stromab SPA’s expertise in crosscutting solutions to enhance its offerings in North America.

Woodworking Technology Days 2023 is just around the corner.

Corporate, Machinery Solutions, Trade ShowsVisit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.