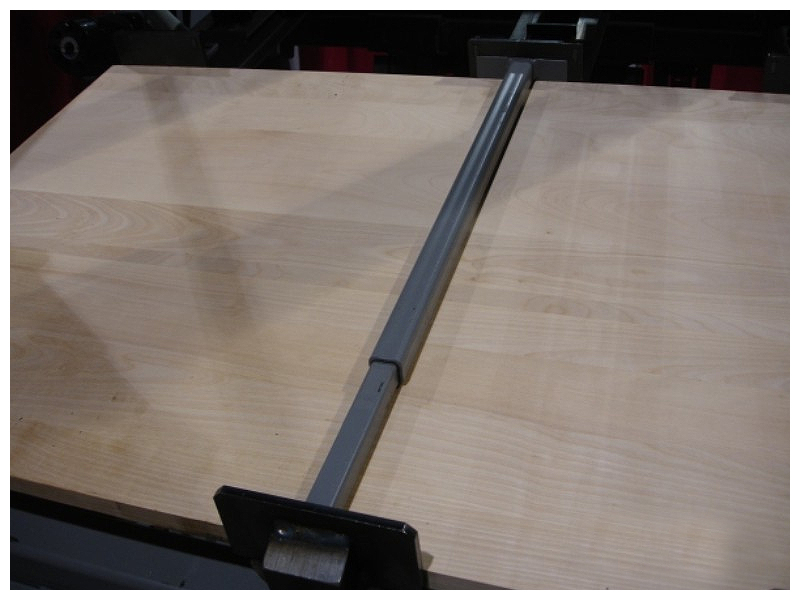

The ideal clamping solution for panels, stair components, rails, posts and architectural millwork.

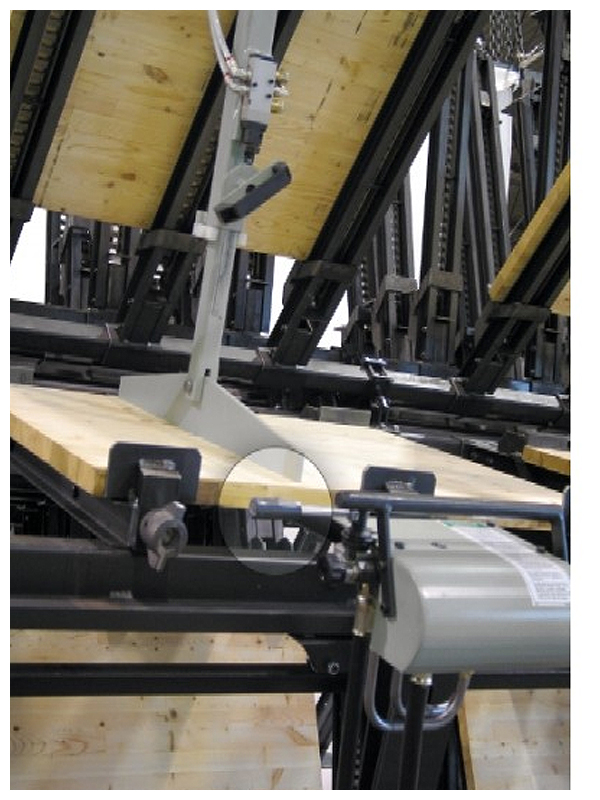

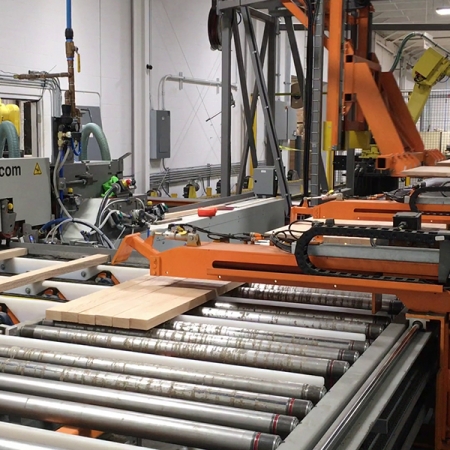

The Doucet SRX Hydraulic Clamp Carrier is an industrial clamp carrier that is available in working lengths from 6 ½’ to 24 ½’ and with 6 to 80 sections (clamping layers). The powerful hydraulic power unit is used for rotating the clamp to the next section and on request is also used for tightening. Available with standard acme screw or rapid change clamps from 2 ½” or 3 ½” with 32” to 52” maximum opening. For thicker material, the clamps can be outfitted with 4” or 6” clamp extenders making it ideal for clamping posts or beams.

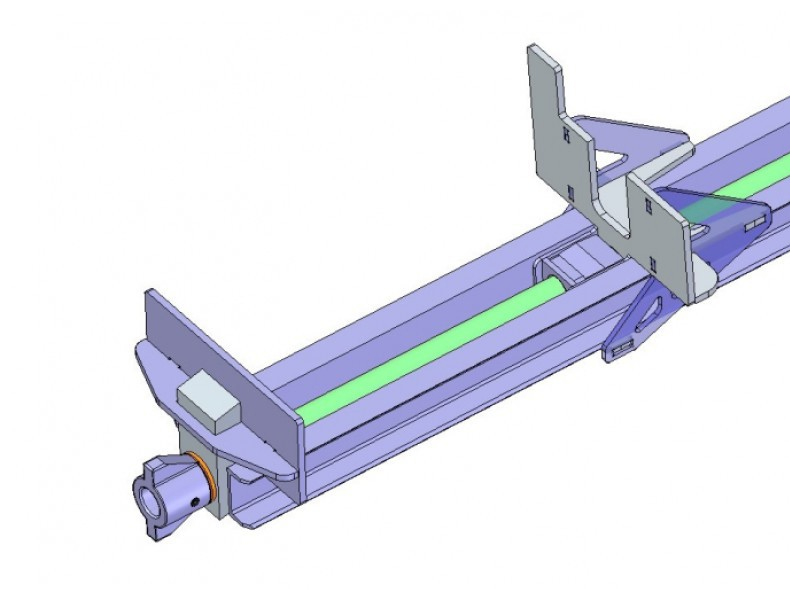

All Doucet SRX clamp carriers come with heavy-duty panel clamps, the heaviest and sturdiest in the industry. The “U-shaped” notched bar never bows improving clamp life. The notches on the clamp allow a rapid positioning of the movable jaw and a gain in efficiency. Clamps are designed to deliver the highest clamping force up to 5000 lb. The torque ratio is infinitely adjustable and capable to reach the perfect pressure at the glue joint. The fixed position 8’’ wide jaw, for high volume applications, increases the productivity by 15 to 20% by removing the non-value-added tasks of the operators to move clamps between panel length changes.

Why Doucet SRX Hydraulic Clamp Carrier?

- Clamp Carriers are available in a wide range of configurations from 6 ½’ to 24 ½’ wide and from 6 to 80 sections

- Heavy duty clamps: 2 ½” or 3 ½” jaw height capacity by 32″ to 52” opening, Rapid change or Acme screw

- Powerful hydraulic unit for rotation and clamping (optional)

- Optional pneumatic panel flattener eliminates uneven panels during clamping process

- Rotative frame according to the required configuration (see Options tab)

- Hydraulic power unit

- Hydraulic tightening tool with joystick control, and built-in torque control valve mounted on a sliding carriage moving across the front rest of the clamp carrier

- Hydraulic rotation motor and speed reducer with joystick forward/reverse control

- Valve for tightening torque calibration relative to material thickness and center to center spacing on clamps (as per pressure charts); for a perfect control over tightening pressure regardless of panel thickness

- Pneumatically actuated front rest and section support

- Panel flattener installed on a sliding carriage with flattering and release commanded by a manual rocking valve, downward force of the panel flattener up to 750 lb

- Light compressed air consumption of only 3 CFM

Dovetails, what’s the big deal?

Machinery SolutionsOnce you open the drawer and see the dovetail design, it elevates your product in the consumer’s eye. But why dovetail machine is right for my operation? When deciding to produce your own drawer boxes, a number of factors come into play when selecting the equipment required.

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.

Kingswood Cabinets. A true commitment to growth.

Case Study, Machinery Solutions, Service and SupportAkhurst is very proud of our involvement in the plant expansion of Kingswood Cabinets of Calgary, Alberta. Kingswood recently relocated to a new state-of-the-art manufacturing facility.