Eliminate hand sanding with our economical sanding and de-nibbing solution for linear profile.

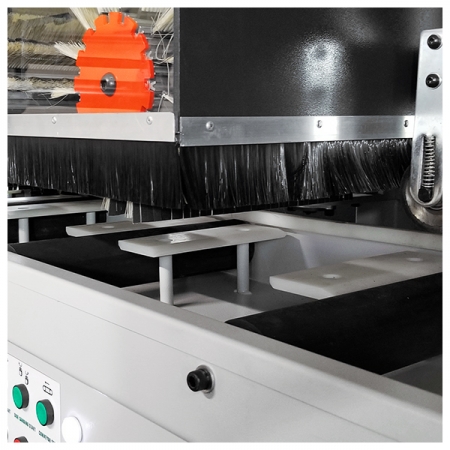

The Cantek LBS300-5S 3-sided lineal brush sander is designed to help with your everyday linear profile sanding needs. It can be used for white wood sanding and sealer sanding of linear parts such as mouldings, flooring, furniture components, window parts etc. The machine works well as a standalone unit, or as part of the finishing line.

Why Cantek LBS300-5S 3-Sided Lineal Brush Sander?

- Designed for sanding linear profiled wood on three sides

- Brushing heads consist of abrasive cloth strips and cleaning brushes and are design to access profiled components.

- Ideal for sanding and defibbing linear products including:

- Moldings, skirting, architrave, flooring

- MDF, hardwoods and softwoods

- Paint, sealer, and lacquer sanding

KEY ADVANTAGES

- Main Frame is fabricated of heavy steel plate and ribbed to minimize vibration and deflection.

- Centralized Control Panel for operator convenience. Clearly Identified & colour coded push buttons simplifying setup & operation

- Variable speed adjustment by inverter (VFD’s) to all brush sanding heads (200-1200 RPM) for optimum sanding results

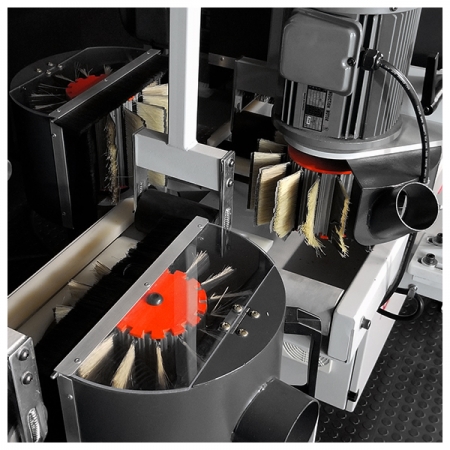

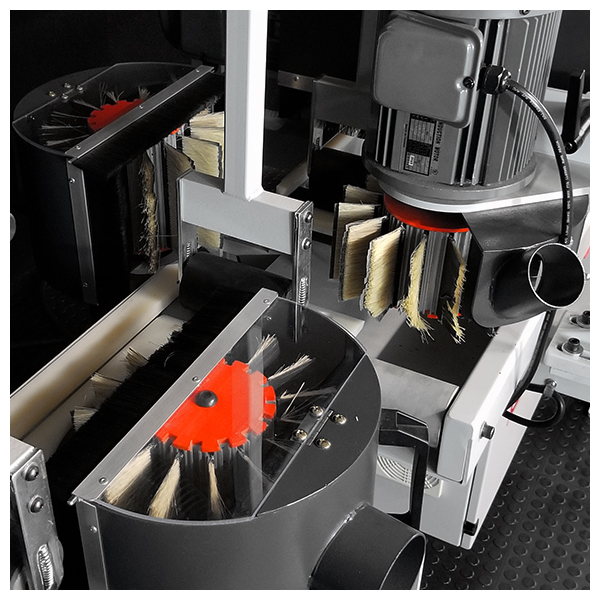

- (2) Sets of top brushing sanding heads with working height adjusted by handwheel and can be set on an angle for bevel siding & angled mouldings

- (1) left side brush sanding head is adjustable up/down, in/out and can be set on an angle

- (1) right side brush sanding head which can be adjusted up/down and in and out and can be set on an angle

- (1) Additional left side sanding head is adjustable up/down, in/out, and can be set on an angle

- Top Press Rolls Working Height adjusted by hand wheel.

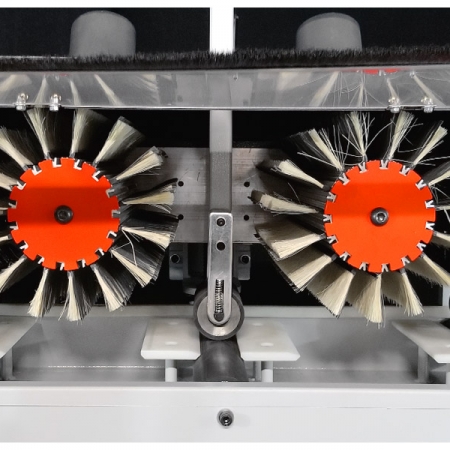

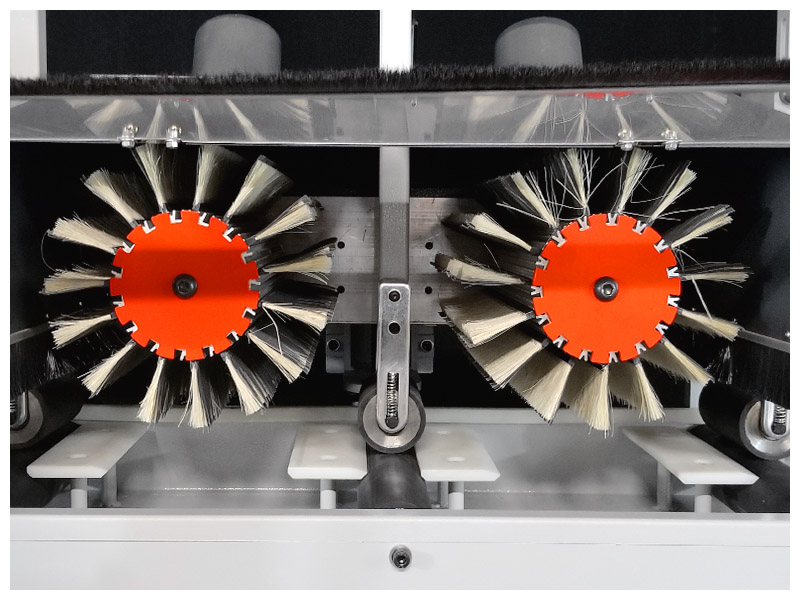

- Brushing head consists of cleaning brush units and abrasive cloth units

- The dovetail pocket design allows for easy abrasive/brush replacement.

SPECIFICATIONS

Dovetails, what’s the big deal?

Machinery SolutionsOnce you open the drawer and see the dovetail design, it elevates your product in the consumer’s eye. But why dovetail machine is right for my operation? When deciding to produce your own drawer boxes, a number of factors come into play when selecting the equipment required.

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.

Kingswood Cabinets. A true commitment to growth.

Case Study, Machinery Solutions, Service and SupportAkhurst is very proud of our involvement in the plant expansion of Kingswood Cabinets of Calgary, Alberta. Kingswood recently relocated to a new state-of-the-art manufacturing facility.