High production horizontal resaw with tiling bed for bevel siding and more.

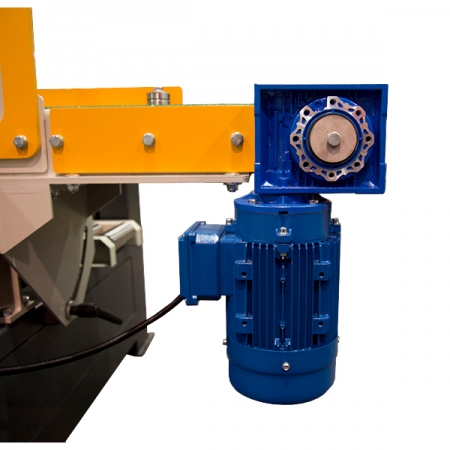

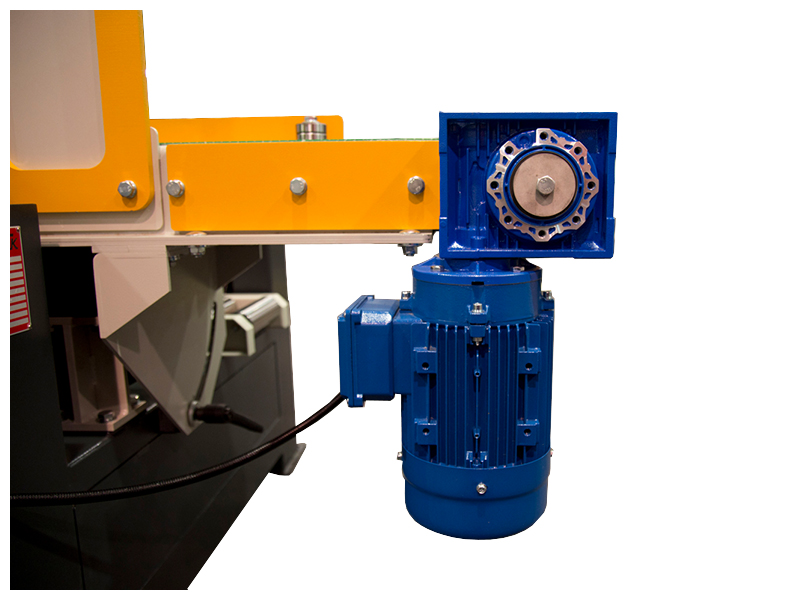

The Cantek HR300PBX tilting bed horizontal band resaw is industrially built for demanding resawing applications. The bed can be tilting from 0-45o making it ideal for bevel siding, moulding blanks, or millwork components. Capable of feeding up to 12” x 12” timber and cutting up to 10” thick. The powerful 30HP saw motor has a variable feed control allowing you to match the cutting speed to your blade & application requirements. The HR300PBX runs a 2” wide blade which runs on solid steel band wheels which are precision machined and balanced for a smooth cutting action. The precision sandwich style blade guides ensure the blade runs true for optimum cutting results. The thickness is conveniently adjusted using a precision motorized digital thickness control.

Why Cantek HR300PBX Tilting Bed Horizontal Band Resaw?

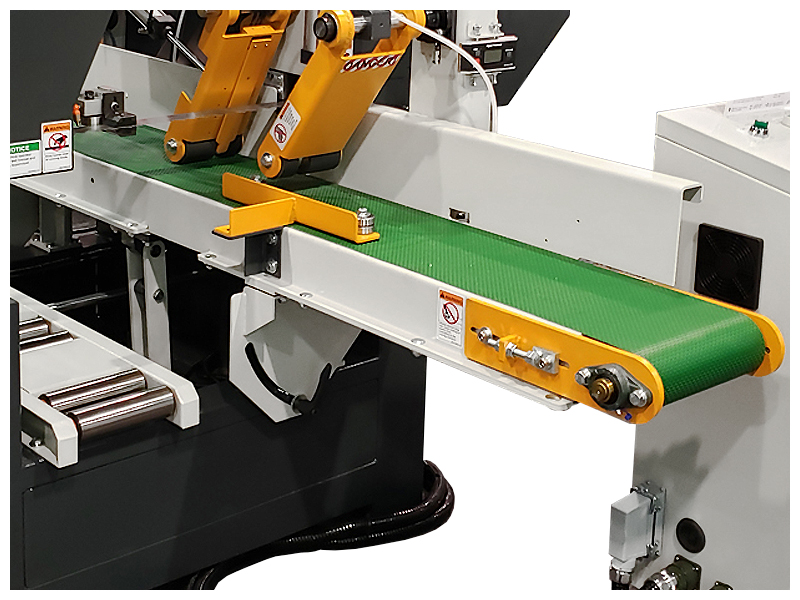

- Manually tilting feed belt for straight of bevel cutting from 0 – 45o

- Powerful 30HP saw wheel motor with variable speed inverter for precise blade speed setting according to your needs

- Heavy-duty tubular steel frame

- Motorized thickness (blade height) adjustment with digital position readout

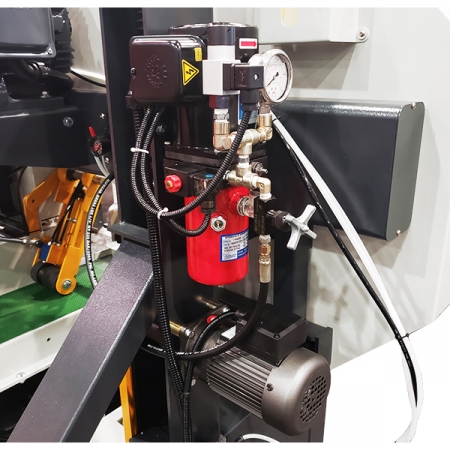

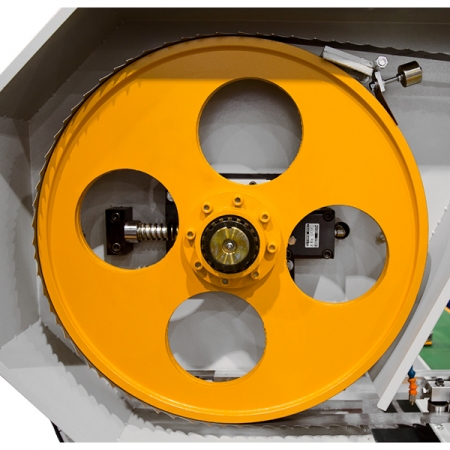

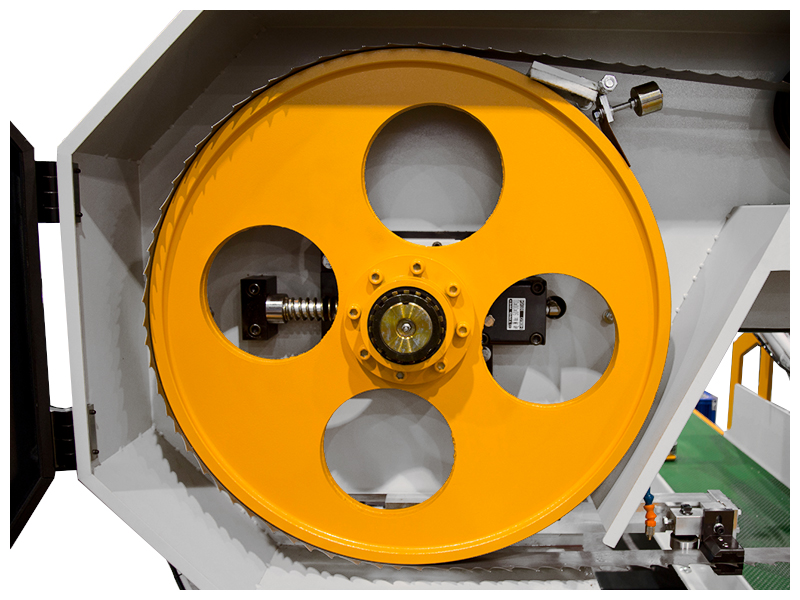

- Hydraulic blade tensioning for optimum cutting results

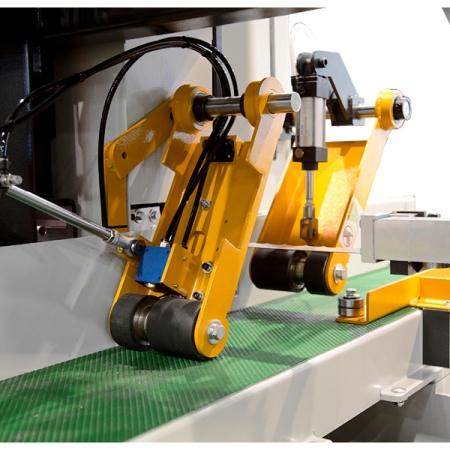

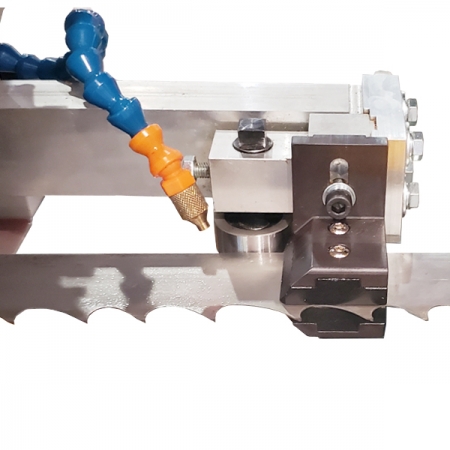

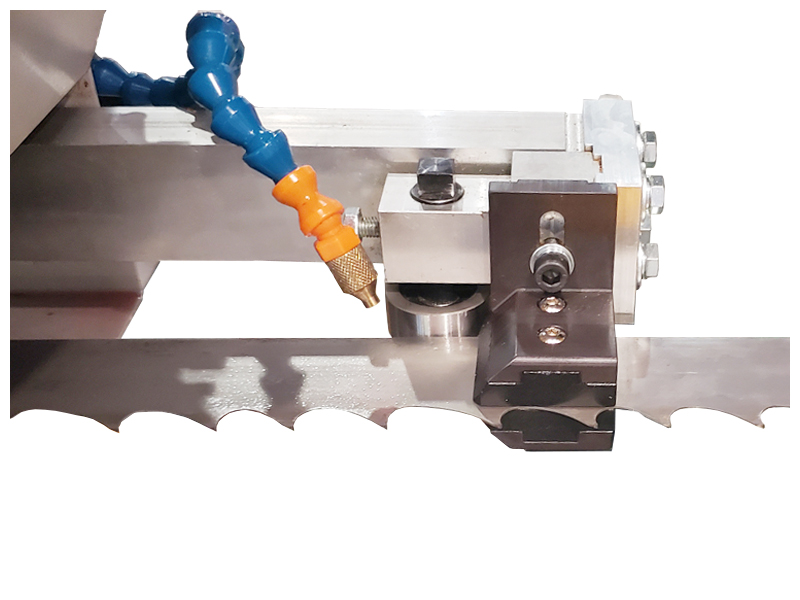

- Precision sandwich style saw guide system with moveable left guide to move as close as desired to the material being cut for improved cut accuracy

- Air mist blade cooling system

- Mobile control panel with digital thickness control, ammeter, feed speed display can be positioned where the operator desires

- Solid steel saw wheels – precision machined and balanced

- Pneumatic pressurized top hold down rollers on feed conveyor

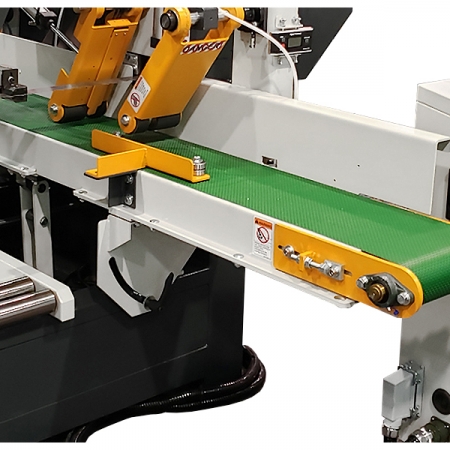

- Heavy-duty infeed guide-fence on conveyor right including holdover system

- Idle roller return conveyor to return parts required additional machining

- Reinforced urethane conveyor belt for positive feeding and long life including

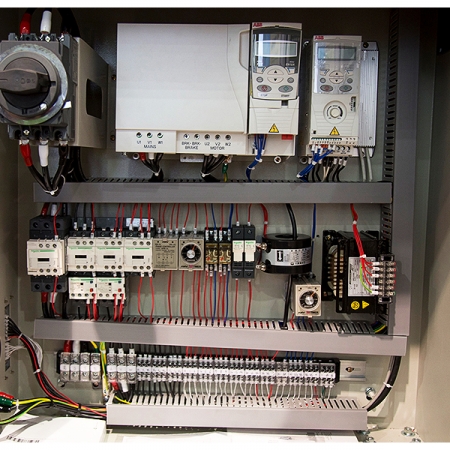

- Variable feed speed by VFD (frequency inverter)

- Y Delta – low amperage starter on the saw motor

- Electrical components to UL/CSA standards – 460/3/60 electrics

- Smooth infeed system (limit switch & timer 1 to 3 seconds) with timed pressure roller

Dovetails, what’s the big deal?

Machinery SolutionsOnce you open the drawer and see the dovetail design, it elevates your product in the consumer’s eye. But why dovetail machine is right for my operation? When deciding to produce your own drawer boxes, a number of factors come into play when selecting the equipment required.

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.

Kingswood Cabinets. A true commitment to growth.

Case Study, Machinery Solutions, Service and SupportAkhurst is very proud of our involvement in the plant expansion of Kingswood Cabinets of Calgary, Alberta. Kingswood recently relocated to a new state-of-the-art manufacturing facility.