Stop throwing money away, turn your wood waste into usable material.

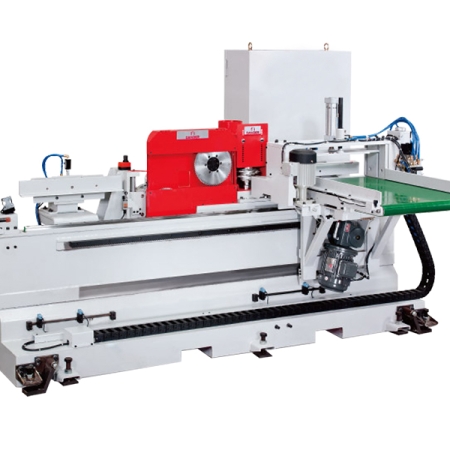

The Cantek FL08 is an automatic finger jointing production line. It is designed to efficiently convert wood waste into valuable materials while maintaining an excellent performance-to-cost ratio. Ideally suited for vertical finger jointing but also suitable for horizontal finger joints with a lower volume requirement. With its innovative technology, this system offers remarkable value in terms of both performance and price, making it a continuous game-changer in the wood industry.

Why Cantek FL08 Automatic Finger Jointer?

- Excellent performance-to-cost ratio

- Only three operators required for maximum production

- Workpieces automatically travel between profiling & gluing stations

- As standard we use PVAc glue but we have optional gluing systems for PUR, MUF, EPI, etc. available upon request

- Available with a press lengths up to 20’

- Length of cut is calculated by an encoder and set on a touch screen for increased accuracy

- Invertor motor is capable of producing 4-5 boards per minute

KEY ADVANTAGES

- Three Operators:

- One operator loads the conveyor before the first shaper unit

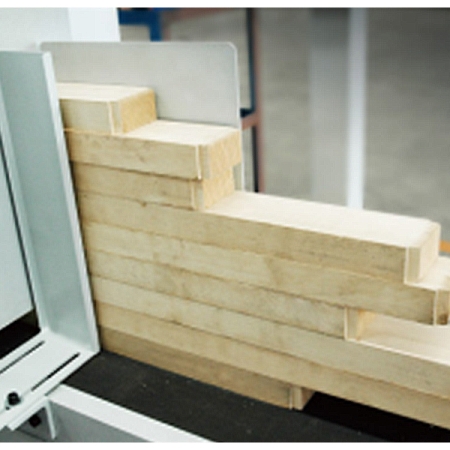

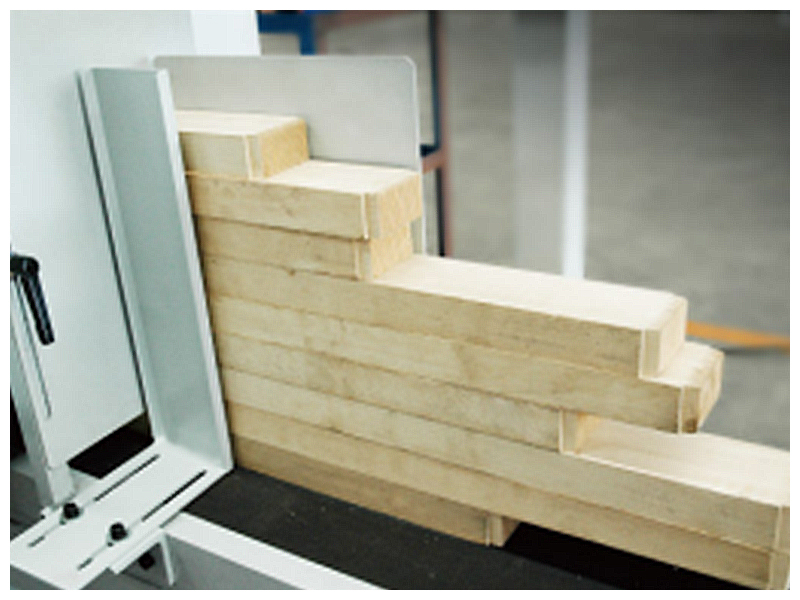

- Second operator loads a hopper before the press section

- Third operator unloads final product from assembly press

- F-C07 and F-C08 finger shapers perform automatic scoring, trimming, shaping, and gluing on both left and right side of workpiece

- Hopper loader is mounted for the operator to stack workpieces, which are then automatically fed into the assembly press

- Synchronized jointing and length cutting is performed in a 2-step process within the F-A05-6 Assembly Press

- Pneumatically loaded feed rollers have air cylinders to always achieve smooth and stable feeding

SPECIFICATIONS

AVAILABLE OPTIONS