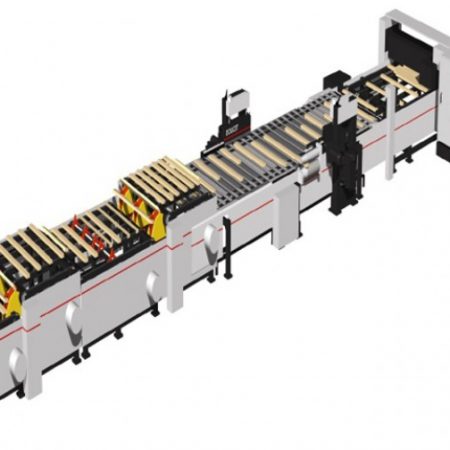

Includes the following:

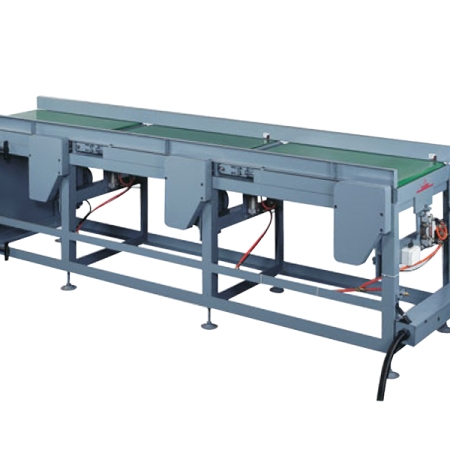

F-I01 Multi-Stage (Three) Initial Conveyor Tables

Auto Feeding Table

|

650 mm (25.6“)

|

Brush Wheel Drive Motor

|

1 HP x3

|

Machine Dimension (L x W x H)

|

3190 x 870 x 970 mm (126 x 35 x 39”)

|

Packing Dimension (L x W x H)

|

3300 x 970 x 1070 mm (130 x 35 x 43”)

|

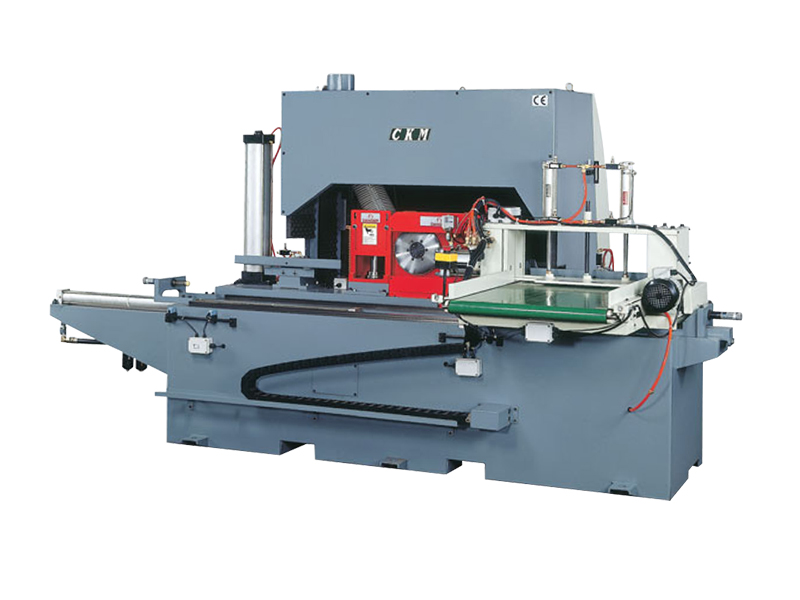

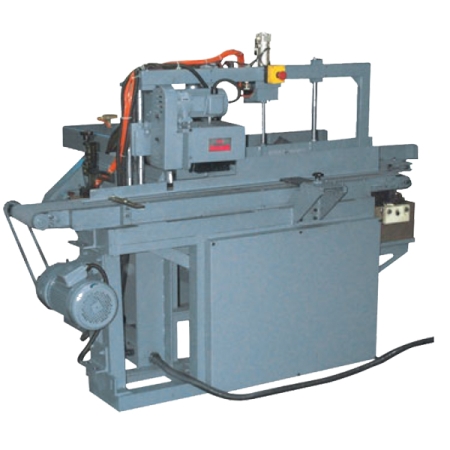

F-C05 Automatic Finger Shaper – Right End

Max. available width working table

|

650 mm (25.6”)

|

Range of workpiece length

|

150~1000 mm (5.9~39.4”)

|

Range of workpiece height

|

30~160 mm (1.2~6.3”)

|

Table moving speed

|

66 FPM

|

Trimming saw speed

|

2800 RPM, 3400 RPM

|

Finger cutter speed

|

5000 RPM

|

Scoring saw speed

|

2800 RPM, 3400 RPM

|

POWER REQUIRED

|

Table-drive motor

|

1/2 HP

|

For conveyor motor

|

1/2 HP

|

Scoring saw motor

|

1 HP

|

Trim saw motor

|

10 HP

|

Shaper cutter motor

|

20 HP

|

Dia of Cutter (in/out)

|

ø70 / ø160 mm (ø2.8 / ø6.3)

|

Dust hood outlet diameter

|

6” x 2”

|

Machine dimensions (L x W x H)

|

3670 x 2155 x 1905 mm (145 x 85 x 75”)

|

Noise Value

|

88.2 Db

|

Packing dimensions (L x W x H)

|

3810 x 2270 x 2120 mm (150 x 90 x 84”)

|

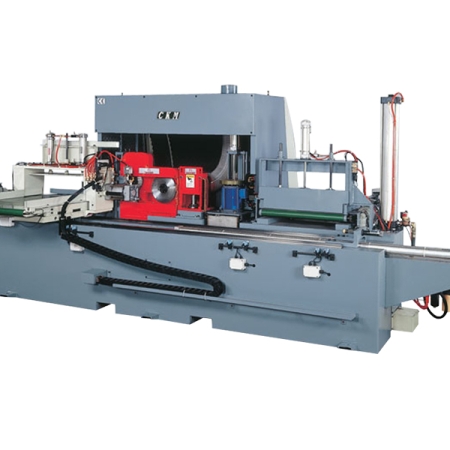

F-C06 Automatic Finger Shaper – Left End

Max. available width working table

|

650 mm (25.6”)

|

Range of workpiece length

|

150~1000 mm (5.9~39.4”)

|

Range of workpiece height

|

30~160 mm (1.2~6.3”)

|

Table moving speed

|

66 FPM

|

Trimming saw speed

|

2800 RPM, 3400 RPM

|

Finger cutter speed

|

5000 RPM

|

Scoring saw speed

|

2800 RPM, 3400 RPM

|

POWER REQUIRED

|

Table-drive motor

|

1/2 HP x2

|

For conveyor motor

|

1/2 HP

|

Scoring saw motor

|

1 HP x 2

|

Trim saw motor

|

10 HP

|

Shaper cutter motor

|

20 HP

|

Dia of Cutter (in/out)

|

ø70 / ø160 mm (ø2.8 / ø6.3)

|

Dust hood outlet diameter

|

6″ x 2”

|

Machine dimensions (L x W x H)

|

4160 × 2155 × 1905 mm (164 x 85 x 75”)

|

Noise Value

|

88.2 Db

|

Packing Dimensions (L x W x H)

|

4855 x 2270 x 2120 mm (192 x 90 x 84”)

|

*1: The standard gluing device is roller TYPE; the tenon depth is 12 mm

*2: Inject/spray type gluing system can be installed upon request

*3: Device options for glues other than standard PVAc glue (PU, MUF, EPI, etc.) upon request

SPECIFICATIONS:

- With 20 HP for Main Spindle

- With 10 HP for Trimming Saw

- With Top and Bottom Scoring Saw, 1 HP x 2

- With 1/2HP (3Ph) for Feeding Conveyor

*Additional units to expand the system are available upon request.

F-D01 Automatic Feeding Table

Auto Feeding Table

|

650 mm (25.6”)

|

Table Height

|

860 mm

|

Range of Material Length

|

100~1000 mm (3.9~39.4”)

|

Range of Material Width

|

30~160 mm (1.2~6.3”)

|

POWER REQUIRED

|

Feed Drive Motor

|

1 HP

|

Outfeed Drive Motor

|

2 HP

|

Brush Wheel Drive Motor

|

1/8 HP

|

Overall Length

|

1540 mm (61”)

|

Overall Width

|

1545 mm (61”)

|

Overall Height

|

2450 mm (97”)

|

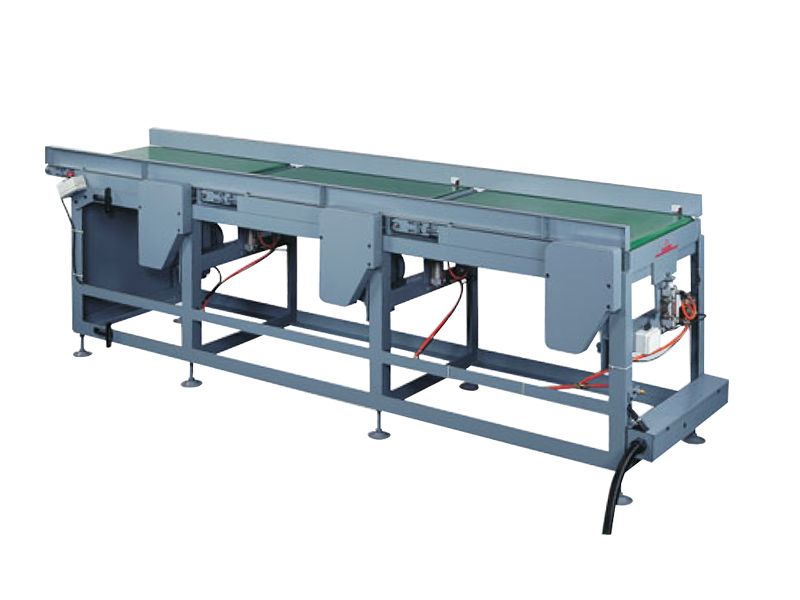

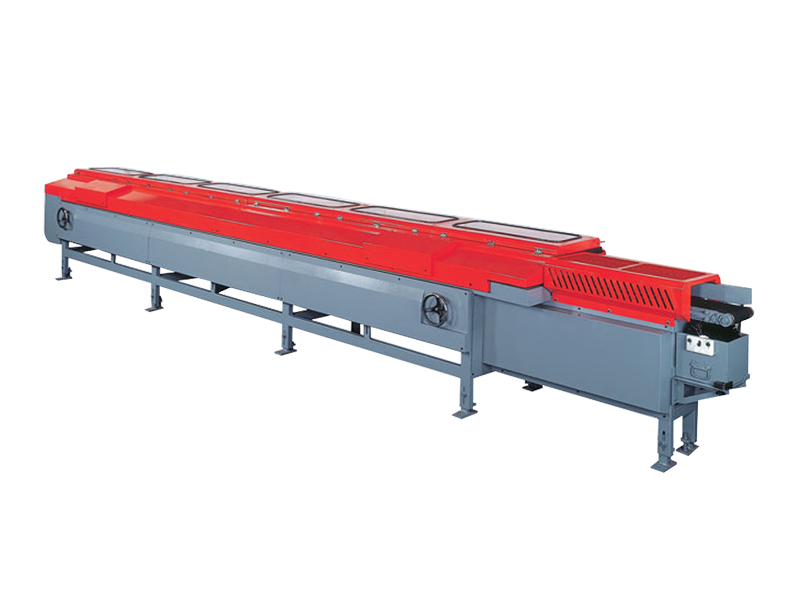

F-T03 Chain drive pre-press assembly stand

Available length of workpiece

|

6000 mm (237”)

|

Available width of workpiece

|

15~200 mm (0.60~7.9”)

|

Available height of workpiece

|

15~100 mm (0.60~4”)

|

Feeding speed

|

263 FPM

|

Capacity length product

|

Max. 4 – 5 PCS/min

|

POWER REQUIREMENT

|

Feed motor

|

2 HP

|

Machine dimensions (L x W x H)

|

6035 x 1000 x 1060 mm (238 x 40 x 42“)

|

Noise level

|

70 Db

|

Packing dimensions (L x W x H)

|

6070 x 1120 x 1275 mm (239 x 44 x 51“)

|

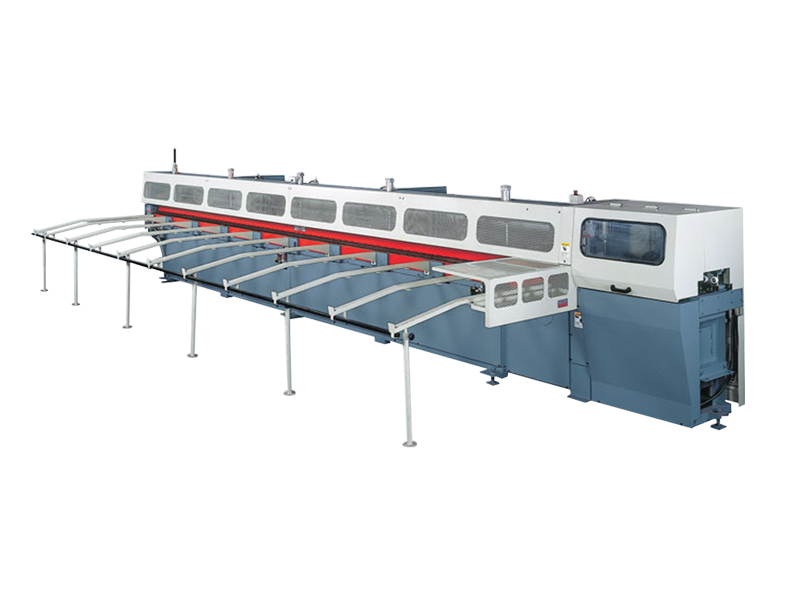

F-A03 Assembly Press

|

|

6 m (20 ft)

|

6.8 m (22 ft)

|

Available Length of Workpiece

|

6200 mm (20 ft)

|

6800 mm (22 ft)

|

Available Width of Workpiece

|

15~160 mm (0.6~6.1”)

|

15~160 mm (0.6~6.1”)

|

Available Height of Workpiece

|

15~60 mm (0.6~2.4”)

|

15~60 mm (0.6~2.4”)

|

Finger Assembly Pressure

|

0~331 lbs/cm²

|

0~331 lbs/cm²

|

Feeding Speed

|

263 FPM

|

263 FPM

|

Capacity Length Product

|

5 PCS/min

|

5 PCS/min

|

POWER REQUIRED

|

Hydraulic Power Unit

|

7 ½ HP

|

7 ½ HP

|

For Feeding

|

2 HP

|

2 HP

|

For Sizing Saw

|

5 HP

|

5 HP

|

Saw Arbor Diameter

|

ø1″ (ø25.4mm)

|

ø1″ (ø25.4mm)

|

Dust Outlet Diameter

|

101.6 mm (4”)

|

101.6 mm (4”)

|

Machine Dimension (L x W x H)

|

7670 x 1510 x 1370 mm

(302 x 60 x 54”)

|

8270 x 1510 x 1370 mm

(326 x 60 x 54”)

|

Noise Level

|

84 Db

|

84 Db

|

Packing Dimension (L x W x H)

|

7745 x 1150 x 1585 mm

(305 x 46 x 63”)

|

8345 x 1150 x 1585 mm

(329 x 46 x 63”)

|