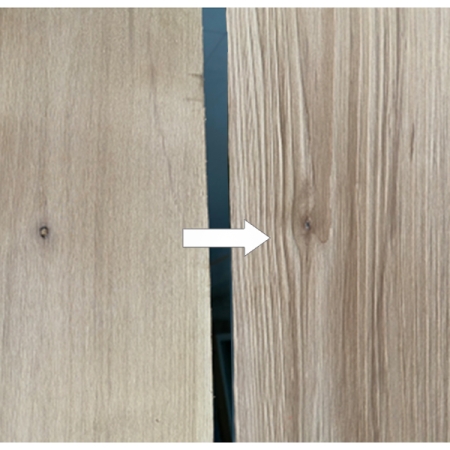

Produce distressed wire brush flooring and paneling with ease!

The Cantek BS600-2H 2-head wire brush machine is designed to remove the soft grain between the growth rings to produce distressed wood flooring, paneling, and more. Following the wire brush head is a nylon brush that is designed to remove any raised fibers that appear from the wire brushing. With variable frequency inverters to control the brush RPM and feed speed you have ultimate control over your finished aesthetic.

Why Cantek BS600-2H 2-Head Wire Brush Machine?

- Ergonomically located machine controls for operator convenience

- Powerful 10 HP motors

- 1st Head wire brush head

- 2nd head abrasive nylon brush (Tynex)

- Equipped with an outboard bearing which supports the brushing spindle

- Rubber hold down rollers

- Rubber conveyor belt to ensure material is fed through the brush heads consistently

- 1 HP feed motor

Machine Controls

Ergonomically located machine controls for operator convenience. Controls include: variable feed speed & RPM controls, individual motor on/off switches, emergency stop, up/down buttons, and forward reverse switch. The digital control displays the material thickness setting, brush RPM, and brush head amp draw for load monitoring.

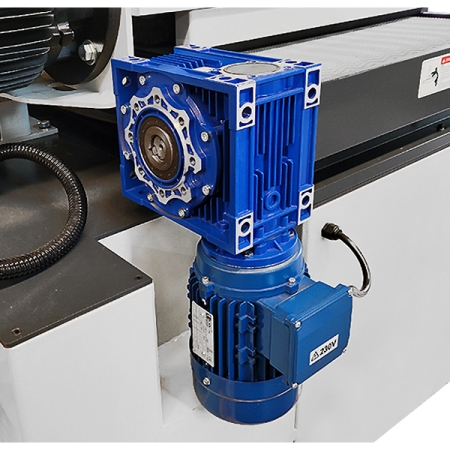

Powerful 10HP Motors

Powerful 10HP brushing motors are controlled by individual VFD inverter controls and reversing switches to allow operator for full control over brushing operations to achieve the desired results.

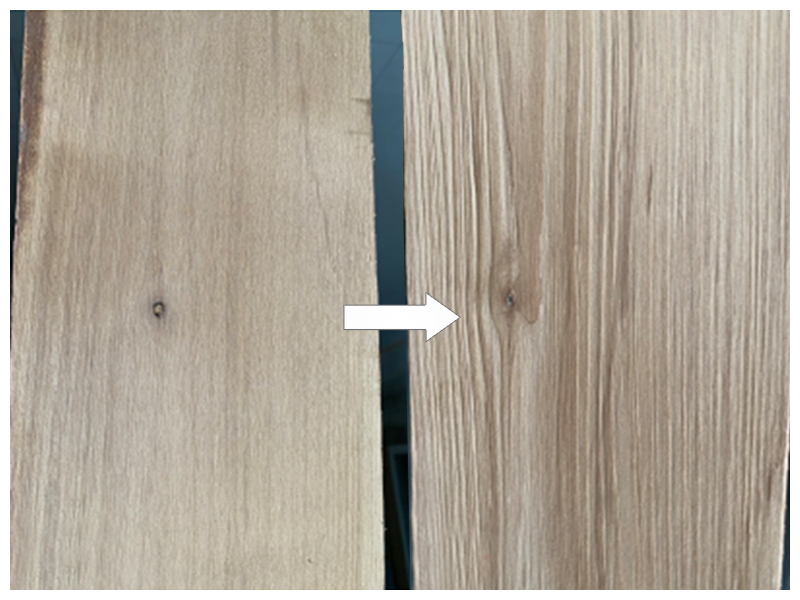

1st Head: Wire Brush Head – Medium Structuring

- Diameter of wire brush head: 10” (254 mm)

- Diameter of wire: 0.35mm

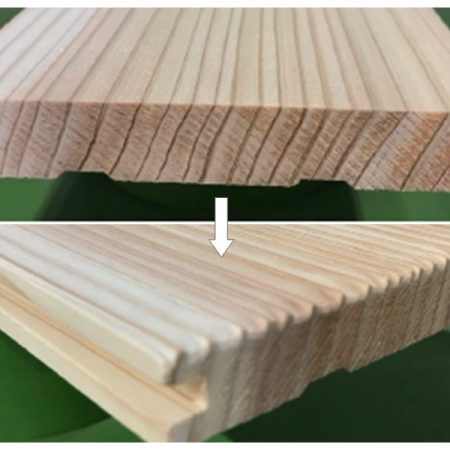

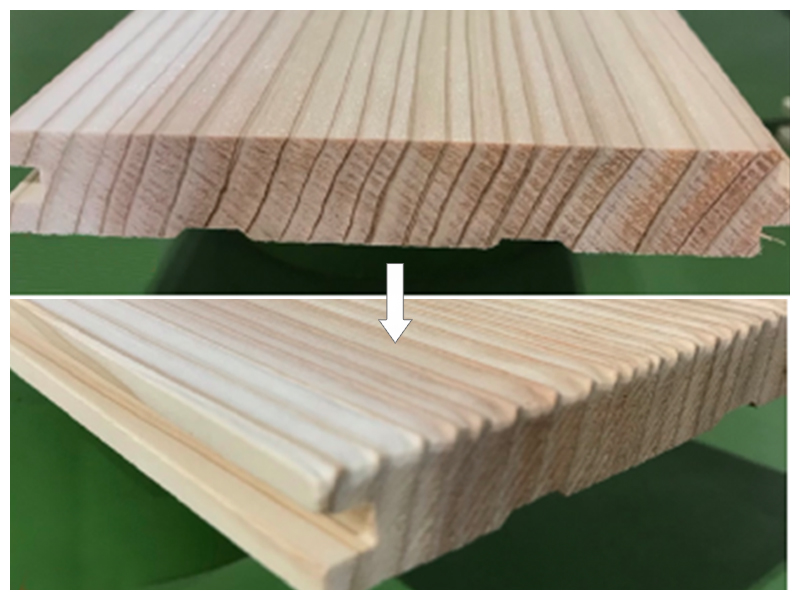

2nd Head: Abrasive Nylon Brush (Tynex)

- Diameter of Abrasive Nylon Brush: 10” (254 mm)

- Brush grit & diameter (standard): 80 Grit (1.25mm)

- The nylon brush is designed to remove any raised fibers that are created during the wire brush operation

Outboard Bearing

Equipped with an outboard bearing which supports the brushing spindle, greatly reducing vibration.

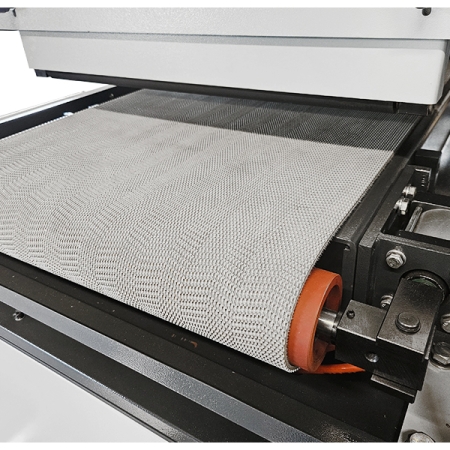

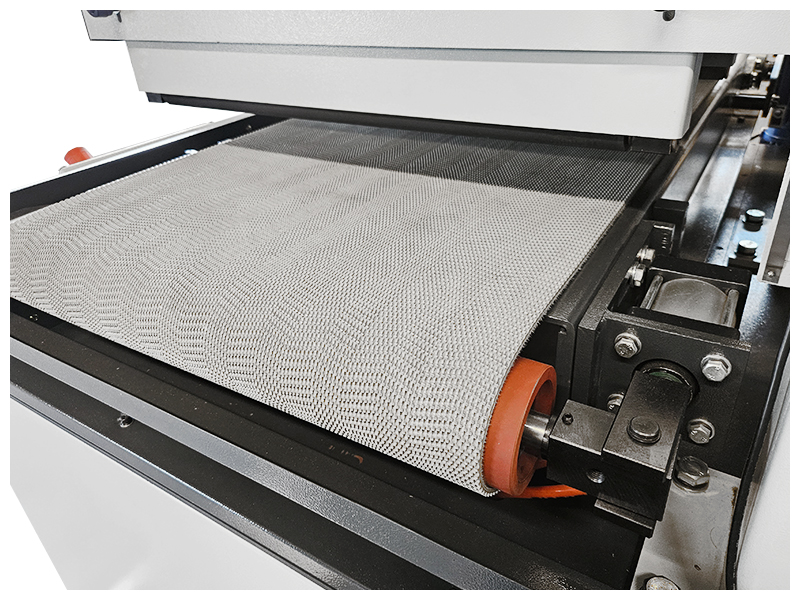

Rubber Hold Down Rollers

Spring loaded rubber hold down rollers before and after each brushing unit ensures material is held firmly on to the conveyor belt during brushing operations.

Conveyor Belt

The rubber conveyor belt ensures the material is fed through the brushing heads consistently. The belt speed is controlled by a variable frequency drive. The belt is equipped with an auto tracking cylinder to ensure it does not over track to one side which prevents it from being damaged.

Feed Motor

The 1HP feed motor is controlled by a variable frequency drive with feed speeds of 7 to 39 FPM.