TIGERSTOP

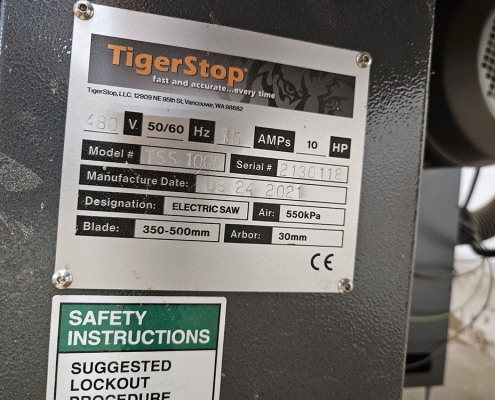

Used Tigersaw 1000 Defecting Optimizing Saw

Machine Information

The TigerSaw 1000™ is the perfect automated push feed saw station for cutting faster and more accurately than manual methods. It increases yield, accuracy and productivity at the best value point in the industry.

PRODUCT HIGHLIGHTS

- Accuracy: +/- 0.012” (0.30 mm)

- Load Capacity: 2100 lbs (952 kg) w/ rollers, 490 lbs (222kg) w/o rollers

- Working Length: 108 ft (32.9 m)

- Saw Motor Power: 10 HP

- Saw Blade Diameter: 450mm or 500mm

WHY YOU NEED A TIGERSAW 1000

Currently, most component cutting is done manually with a tape measure or manual stops. This is slow and inaccurate. TigerSaw 1000 greatly increases throughput while achieving maximum yield, without the need to hire additional operators.

TigerSaw 1000 offers all of the features and benefits of saws costing 2 to 3 times as much. It comes with an adjustable cutting envelope so you can set the envelope to the needed width of the material you are cutting, whether single piece flow or pack. TigerSaw 1000 can handle large pack loads up to 2,100 lbs. when using the HeavyDuty 2 pusher.

TigerSaw 1000’s Dynamic Optimization software gives you the best yield by determining the optimal cutting order from your parts list. TigerSaw 1000’s Crayon Defect Marking allows you to remove defects (knots, wane, discoloration) from your material in-house, for even greater savings.

TigerSaw 1000 is available with table configurations that are flat or tilted 10 degrees. It is easy to install and maintain, comes with a ton of built in safety features, and is simple for operators to use.

DROP A GRADE AND SAVE

Most shops buy expensive defect free material to get the best yield possible. With TigerSaw 1000, defecting your own material is faster and easier than ever before. Drop an entire lumber grade, save on your material bill, and quickly defect material in-house. Use a UV Crayon to mark knots, wane, and discoloration. TigerSaw 1000 will cut around the defects and optimize clear material while running through your cut list. Combined with Dynamic Optimization™, TigerSaw 1000 gives operators the ability to cut around defects while achieving the maximum yield. In most cases, shops buying FAS or SEL grade are able to downgrade to #1 Common while still achieving the same yield. This is typically a 20% to 30% savings in material cost.