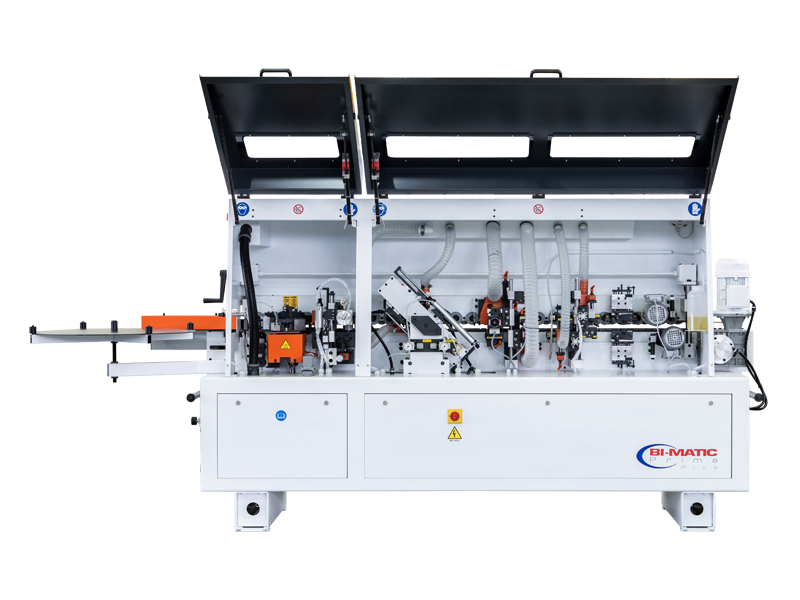

A Compact, Reliable, and Affordable Edgebanding Solution.

The Bi-Matic Prima Plus 5.3 edgebander will apply edgebanding from 0.4mm to 3mm and is specially designed for applying coil edgebanding on cabinet and case good components. The patented screw glue roller from Bi-Matic ensures a consistent and constant glue delivery to the panel even on long and thick parts. The screw glue roller is also capable of applying thinner viscosity glues including Polypropylene to virtually eliminate the glue line.

Why Bi-Matic Prima Plus 5.3 Edgebander?

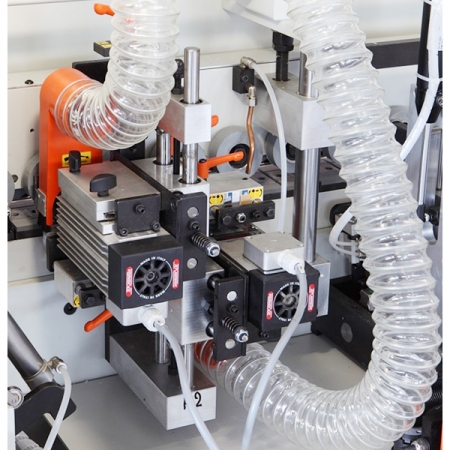

- Patented screw glue rollers allows for superior glue delivery even on long panels and is capable of running thinner viscosity glues like Polypropylene for virtually invisible glue joints

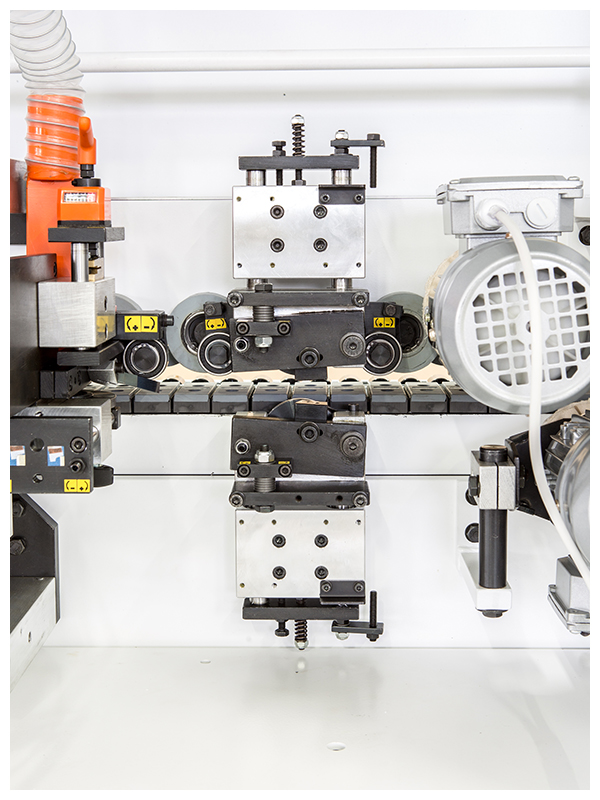

- High frequency dual motor end trim with auto chamfering of the blades from 0-15o

- High frequency top & bottom trimmers equipped with nesting tracing rollers

- Radius scraping unit with 2mm tooling and equipped with nesting tracing rollers

- Glue scraping unit for removing any excess glue

- Buffing station for polishing edge

KEY FEATURES

- Teflon coated gluepot with quick heat up time of 5-6 minutes.

- 650mm diameter coil support tray for holding coil edgebanding

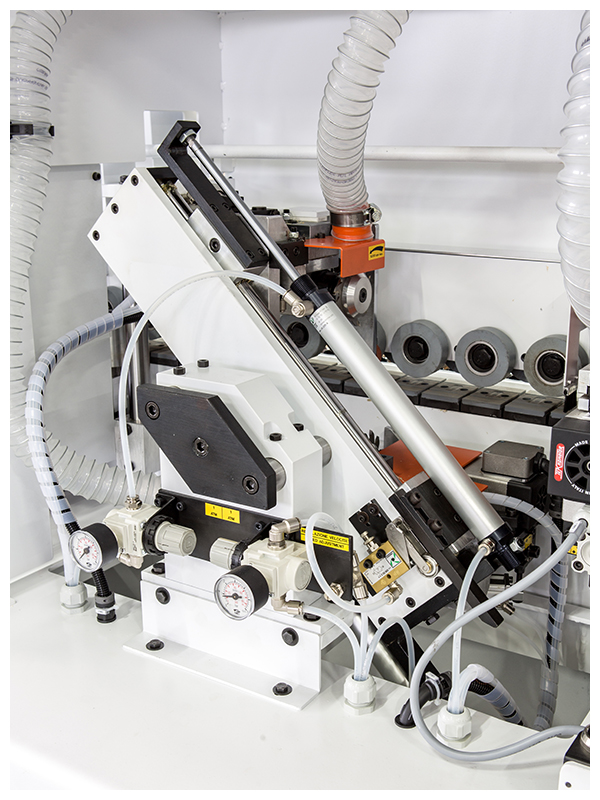

- 3mm guillotine for cutting 3mm edgebanding up to 54mm wide

- Pressure zone consist of (1) driven and (2) idle pressure rollers

- Microprocessor control for turning on and off all working units and control the glue pot temperature

- Dual high frequency motor end trim which can be automatically inclined from 0-15o from the control panel

- High frequency top and bottom trimmers with nesting tracking rollers and equipped with the Easy-Set system for quick adjustment between various pre-set thicknesses

- Equipped with multi function insert tooling for flush and radius trimming (2mm)

- Radius scraping unit with 2mm radius tooling with upper nesting rollers and can be pneumatically activated by the control panel. It is also equipped with the Easy-Set system

- A chip box collects the scrapings to ensure they do not enter the dust collector

- Anti-adhesive liquid sprinkler installed in prior to the scraping unit

- Glue scraping unit with rotating tracer wheels to remove any excess glue to provide a pristine finish on the panel

- Top & bottom buffing units to polish the edge of the panel

SPECIFICATIONS

Pre-milling for Edgebanders.

Machinery SolutionsMore often today you are finding features on smaller edge banders that initially were exclusive to larger, higher production machines. One of those features is pre-milling. Pre-milling consists of two counter-rotating cutterheads which are designed to mill the edge of the panel prior to applying the edge banding material.

Proper edgebander maintenance.

Machinery SolutionsEdgebanders are one of the more complex machines in operation in most cabinet and millwork shops. The maintenance however is imperative to the performance and reliability of the machine. Without it you can experience a poor edge quality which will result in hand finishing and defects and worst of all significant down time and expense […]