Switch to automated coating easily and cost-effectively.

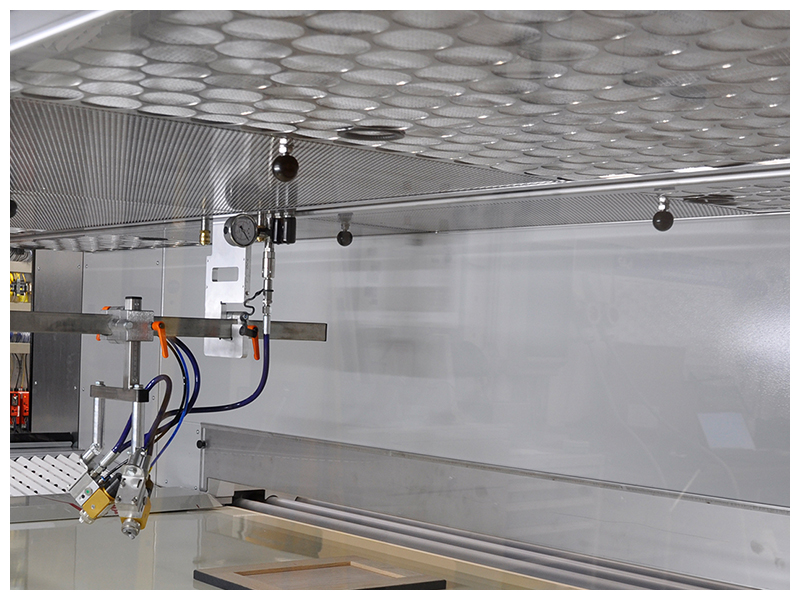

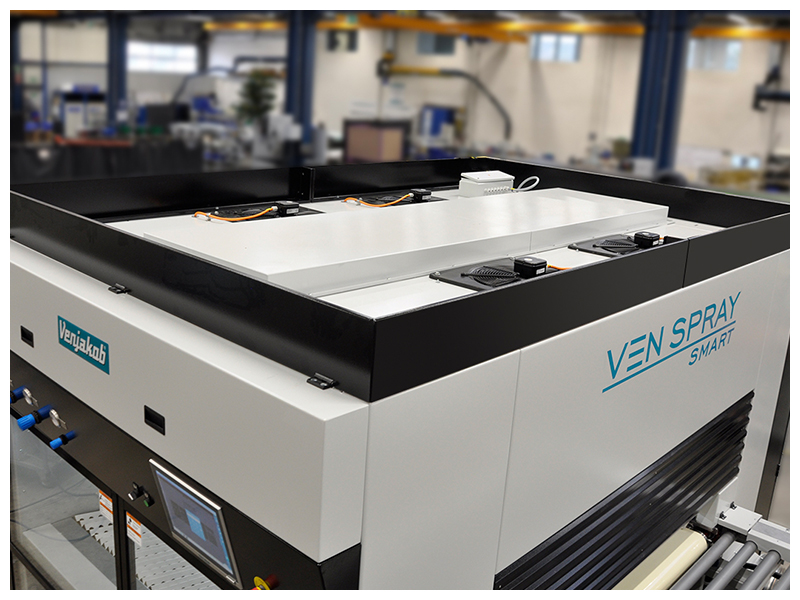

The Venjakob VEN SPRAY SMART Spray Machine is designed to meet flexible production requirements and can be used for solvent and water based paints. It is both, economical and environmentally friendly, and can be used as a stand alone solution or implemented in a production line. The VEN SPRAY SMART can optionally be equipped with a belt cleaning system and/or a paper transport belt. This makes it possible to alternate between both modes of operation. A quick change between two paint systems (water/solvent based) is simple and fast. This makes it especially attractive for smaller companies to replace manual painting.

Why Venjakob VEN SPRAY SMART Spray Machine?

- One of a kind belt cleaning system and/or paper belt conveyor system to save material and reduce cleaning effort

- Paint recovery device is economical and environmentally friendly

- One to three paint supply circuits

- Easy to maintain dry filter extraction system

- Filtered supply air

- Control cabinet with Beckhoff Industrial-PC and touch display

- Modular expandable (dust-removal unit, dryer, etc)

- Small quantity paint supply container optional available

- Belt cleaning system and|or paper belt conveyor system save material and reduce the cleaning effort

- The machine is immediately operational (low installation time), operator friendly and low maintenance

- Implemented switch control cabinet

- Paint recovery device is economical and environmentally friendly

- 1-3 paint supply circuits

- Easy to maintain dry filter extraction system

- Air supply ventilator with filter

- Infinitely variable throughfeed speed

- Switch cabinet with Beckhoff Industrial-PC and touch display

- Modular expandable (dust removal unit, dryer…)

- Process reliability

- Reproducible results

- Low floor space required

- Small quantity paint supply container optional available

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.