Speed up your crosscutting operations.

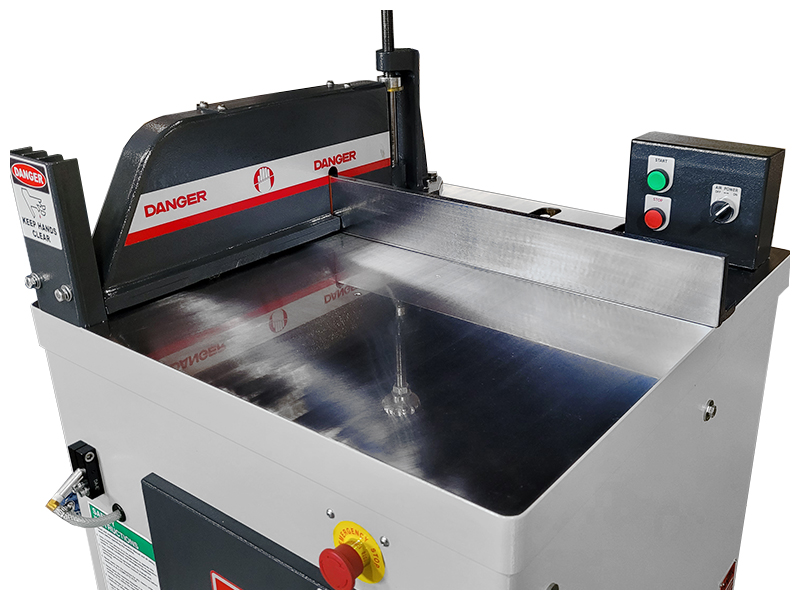

The Cantek PCS18M 18″ Non-Ferrous Pneumatic Chop Saw is the ideal solution for increasing production on crosscut operations while maintaining optimum safety. Its powerful 10HP motor and adjustable cutting stroke ensure it can effortlessly cut though a wide range of materials and dimensions. A number of features are included to ensure safe operation such as the infeed/outfeed safety guard, microswitches on all access doors, security bolt on the saw access door, blade misting system, and solid chrome table. Available in either left hand or right hand operation depending on your ideal production flow.

Why Cantek PCS18M 18″ Non-Ferrous Pneumatic Chop Saw?

- Large cutting capacity of 2”x12” up to 4”x10”

- Adjustable cutting stroke to ensure optimum cutting speed and cut quality

- Reliable performance day in and day out

- Added safety features

- Available in Right Hand & Left Hand configuration

- Cut off capacity (thickness x width): 2″ x 12″, 3″ x 11″, 4″ x 10″

- Powerful 10HP main motor

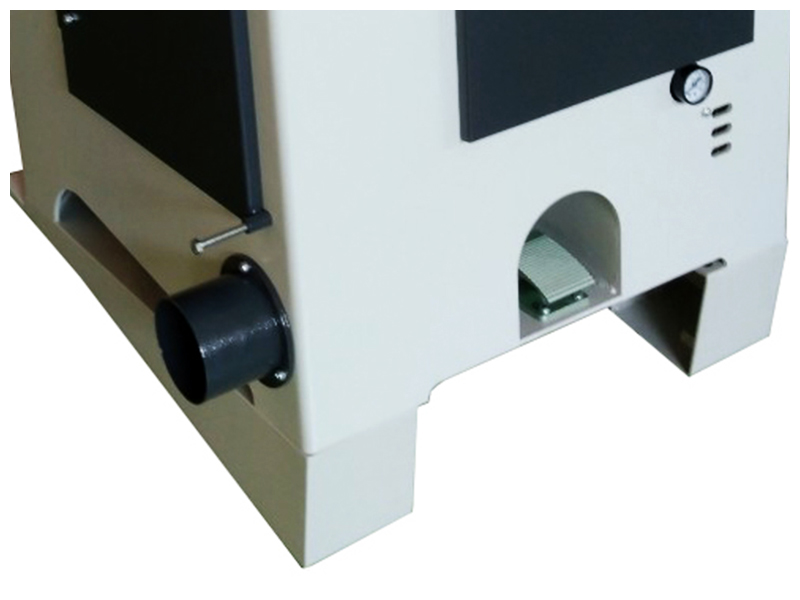

- Pneumatic foot pedal operation with adjustable cutting speed from the front of the machine (Optional dual push bottom control)

- Fast cutting cycle with up to 45 strokes per minute

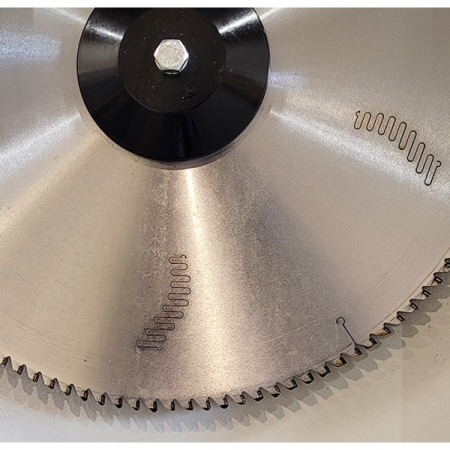

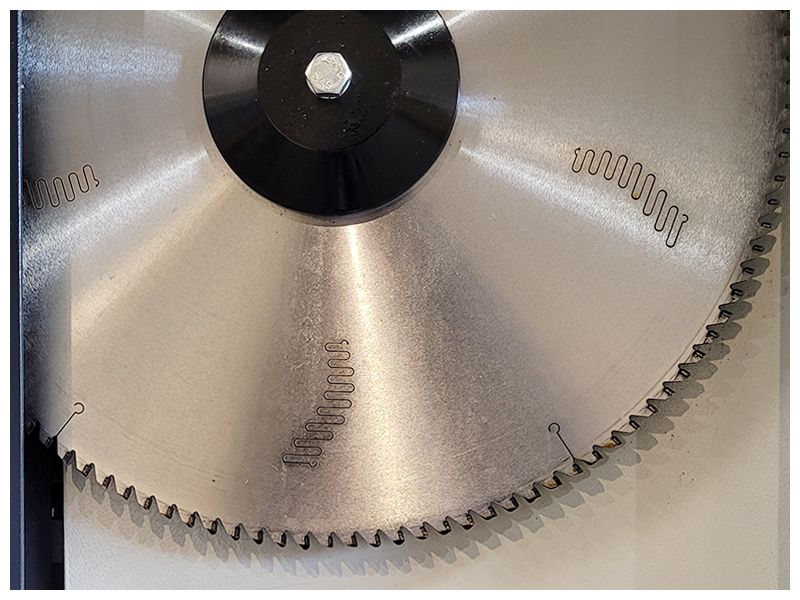

- Non-ferrous cutting blade

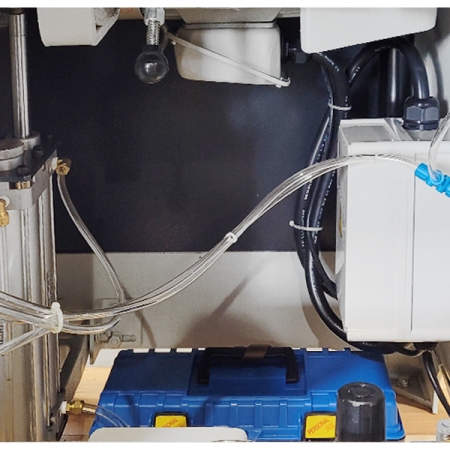

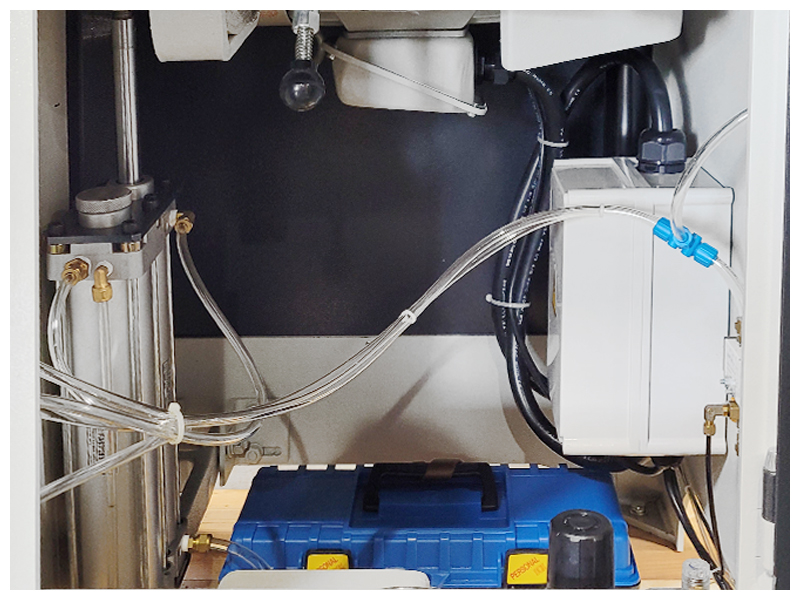

- Air over oil for precise speed control

- Blade misting system that applies a thin film of lubricant for preventing friction build up, and maximizes saw productivity and blade life

- Corrosion resistant solid chrome table

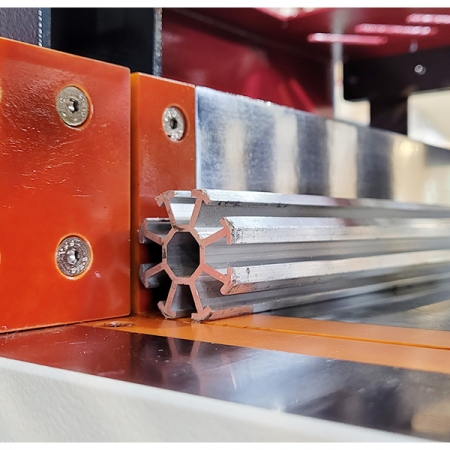

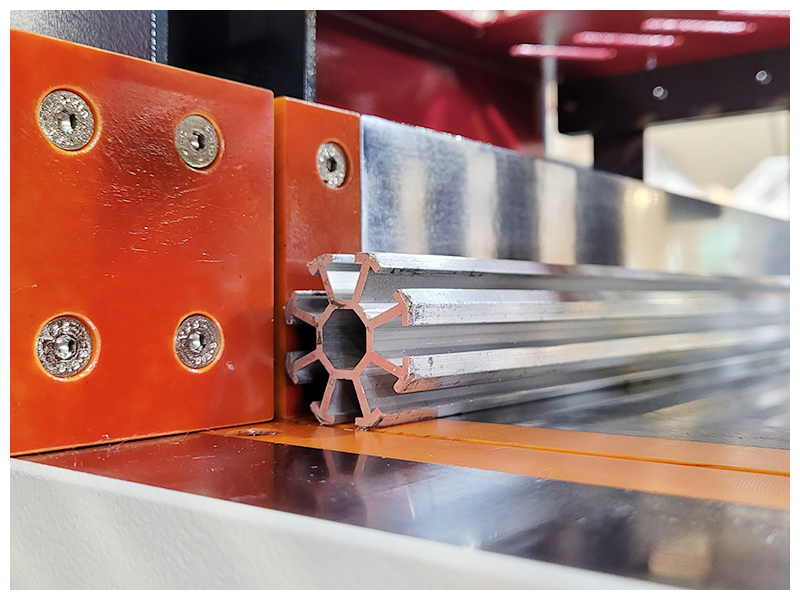

- Zero cut line with T-clamp that increases precision cuts and reduces possibility of tear out

- Material clamp is easily adjusted for workpiece thickness variation.

- CSA/UL magnetic switch

Akhurst Machinery Group announces strategic partnership to aid North American housing crisis.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the North American machinery industry, is pleased to announce a strategic partnership with Modular Building Automation (MBA), a Dutch company specializing in machinery for prefabricated homes, modular buildings, and offsite construction solutions. MBA, a joint venture of the renowned companies J.J. Smith in the UK and Ireland and H&M headquartered in the Netherlands, is involved in the design, manufacturing, distribution, and worldwide sales of MBA equipment.

Akhurst Machinery Group announces strategic partnership with Stromab.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the machinery industry, proudly announces a strategic partnership with Stromab SPA, an Italian manufacturer of innovative crosscutting solutions. This collaboration signifies a major commitment by both companies to bring cutting-edge technology and comprehensive solutions to the North American market. Akhurst Machinery Group, the parent company behind the well-known brands of Cantek and Leadermac USA, will leverage Stromab SPA’s expertise in crosscutting solutions to enhance its offerings in North America.

Woodworking Technology Days 2023 is just around the corner.

Corporate, Machinery Solutions, Trade ShowsVisit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.