Switch to automated coating easily and cost-effectively.

The Venjakob VEN SPRAY ONE Spray Machine gives you the opportunity to set a trendsetting step into automation. The compact painting machine with established and reliable technology offers an interesting alternative for handicraft businesses as a replacement or supplement to the manual spraying station.

The stand-alone solution comes with an integrated control cabinet. Therefore start-up can be carried out quickly and easily, which saves installation costs and time. The solid and inexpensive technology convinces the users of the performance and surface quality produced.

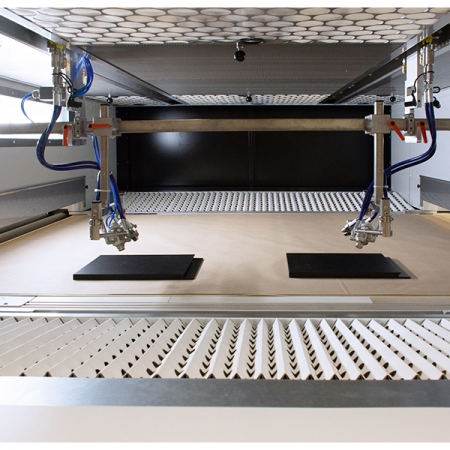

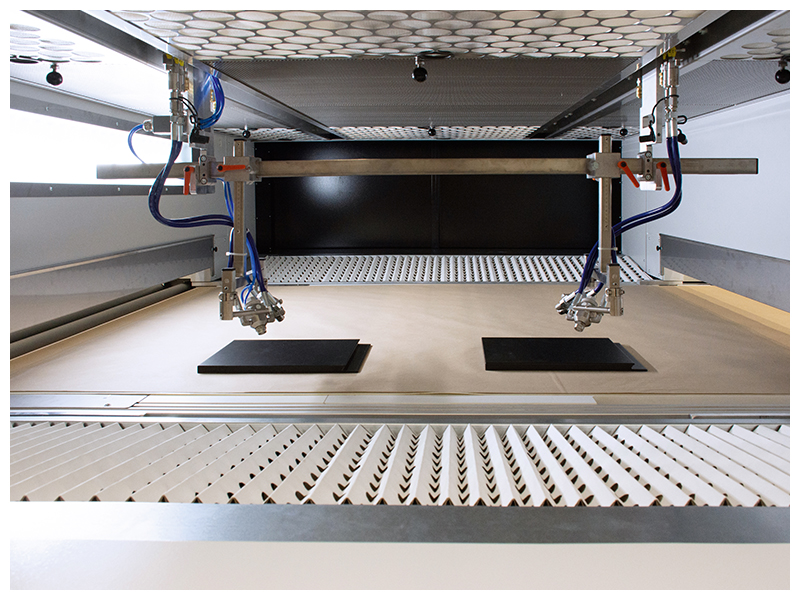

The entry-level model is in no way inferior to the professional range in terms of design and energy efficiency. It also has a large-volume spray booth and long-lasting, energy-efficient LEDs. The VEN SPRAY ONE is designed for the use of 4 spray guns. In order to achieve reproducible quality, recipes can be stored in the system control and called up quickly and easily. The cleaning effort of the painting system is very low, it is equipped with a paper belt transport.

Why Venjakob VEN SPRAY ONE Spray Machine?

- Effective replacement or supplement to a manual spray booth

- Reproducible surface results in top quality

- Simple machine operation with an intuitive user interface

- Cost-effective stand-alone solution in the usual Venjakob quality

- Easy maintenance

- Short delivery time (approx. 4 weeks)

Venjakob wants to meet the requirements of carpenters and craft companies with its new spray coating machine. It´s time to explore new horizons. Let the VEN SPRAY ONE and our team inspire you for new manufacturing processes.

- Spray Booth

- Gun Drive ONE

- Exhaust System DRY 7000

- Light Barrier Control

- Electrical Control Cabinet

- Air Filter Ceiling AV

- Paper Belt System

- Paint Supply Line Diameter 6 (2x)

Dovetails, what’s the big deal?

Machinery SolutionsOnce you open the drawer and see the dovetail design, it elevates your product in the consumer’s eye. But why dovetail machine is right for my operation? When deciding to produce your own drawer boxes, a number of factors come into play when selecting the equipment required.

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.

Kingswood Cabinets. A true commitment to growth.

Case Study, Machinery Solutions, Service and SupportAkhurst is very proud of our involvement in the plant expansion of Kingswood Cabinets of Calgary, Alberta. Kingswood recently relocated to a new state-of-the-art manufacturing facility.