Switch to automated coating easily and cost-effectively.

The Venjakob VEN SPRAY ONE Spray Machine gives you the opportunity to set a trendsetting step into automation. The compact painting machine with established and reliable technology offers an interesting alternative for handicraft businesses as a replacement or supplement to the manual spraying station.

The stand-alone solution comes with an integrated control cabinet. Therefore start-up can be carried out quickly and easily, which saves installation costs and time. The solid and inexpensive technology convinces the users of the performance and surface quality produced.

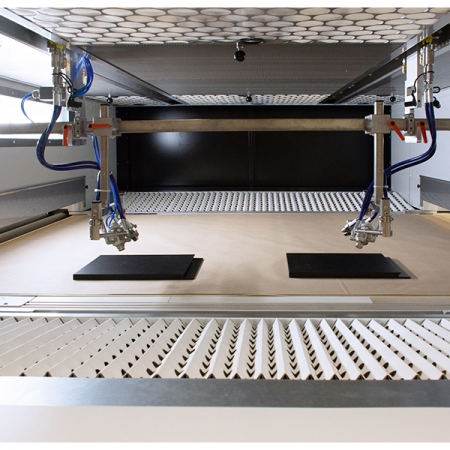

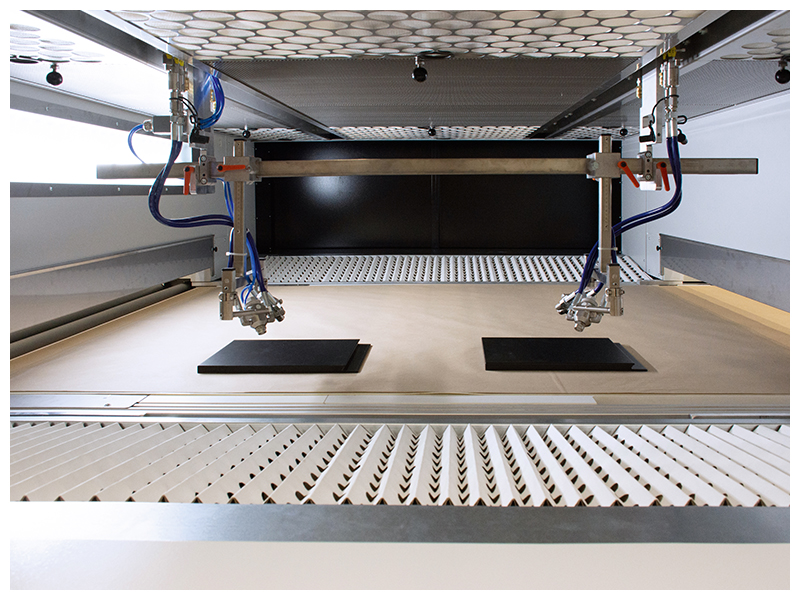

The entry-level model is in no way inferior to the professional range in terms of design and energy efficiency. It also has a large-volume spray booth and long-lasting, energy-efficient LEDs. The VEN SPRAY ONE is designed for the use of 4 spray guns. In order to achieve reproducible quality, recipes can be stored in the system control and called up quickly and easily. The cleaning effort of the painting system is very low, it is equipped with a paper belt transport.

Why Venjakob VEN SPRAY ONE Spray Machine?

- Effective replacement or supplement to a manual spray booth

- Reproducible surface results in top quality

- Simple machine operation with an intuitive user interface

- Cost-effective stand-alone solution in the usual Venjakob quality

- Easy maintenance

- Short delivery time (approx. 4 weeks)

Venjakob wants to meet the requirements of carpenters and craft companies with its new spray coating machine. It´s time to explore new horizons. Let the VEN SPRAY ONE and our team inspire you for new manufacturing processes.

- Spray Booth

- Gun Drive ONE

- Exhaust System DRY 7000

- Light Barrier Control

- Electrical Control Cabinet

- Air Filter Ceiling AV

- Paper Belt System

- Paint Supply Line Diameter 6 (2x)

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.