Structural robotics done right.

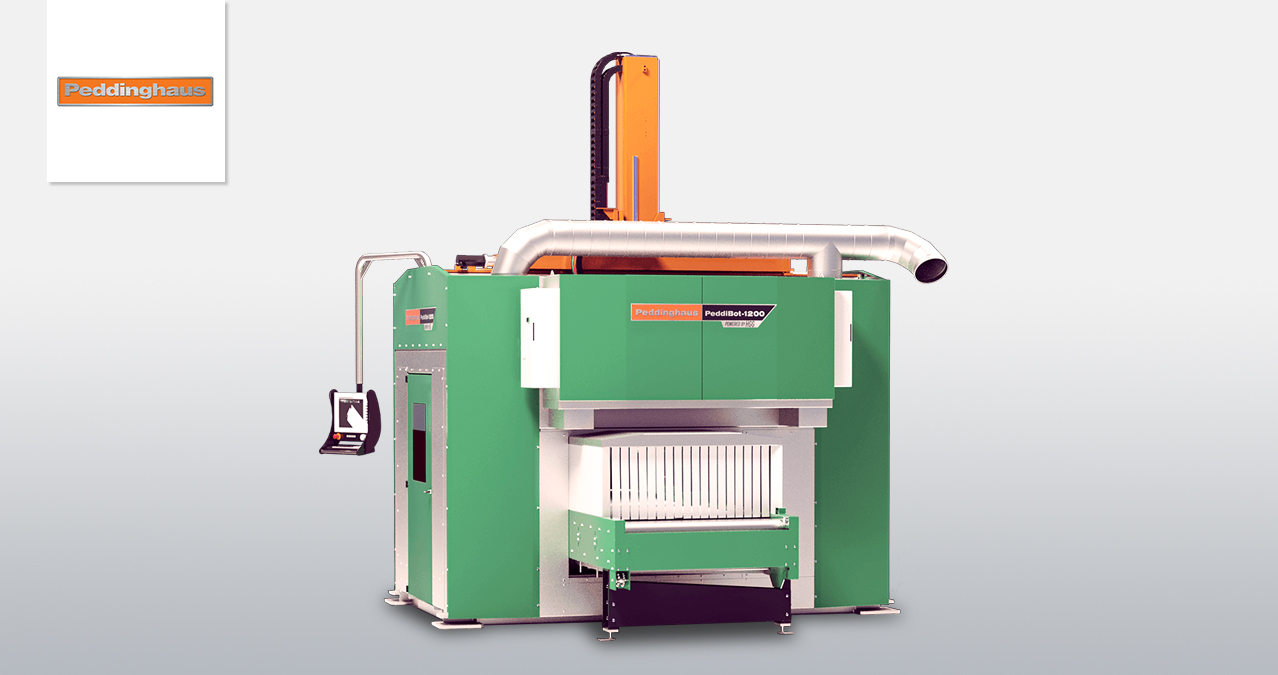

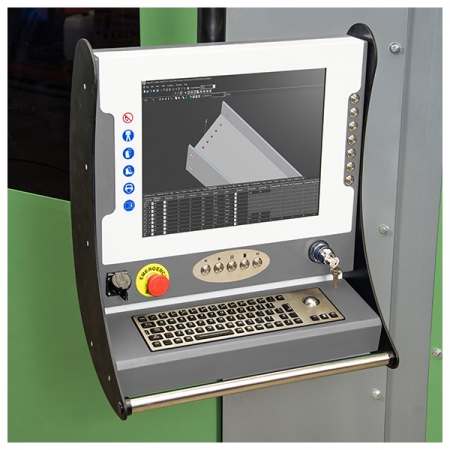

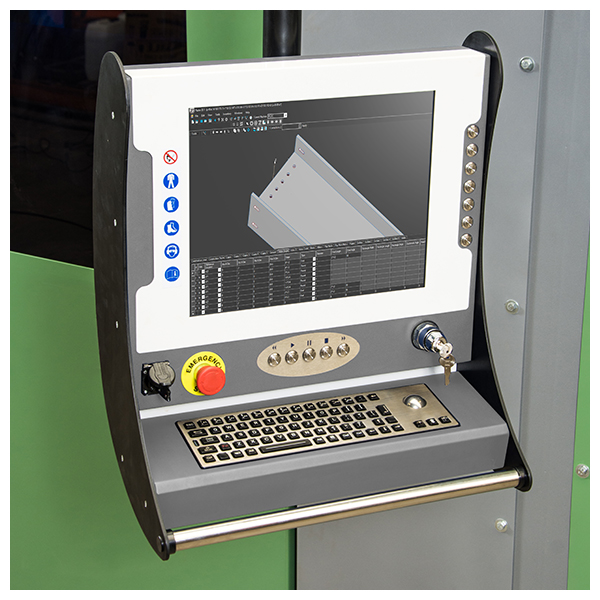

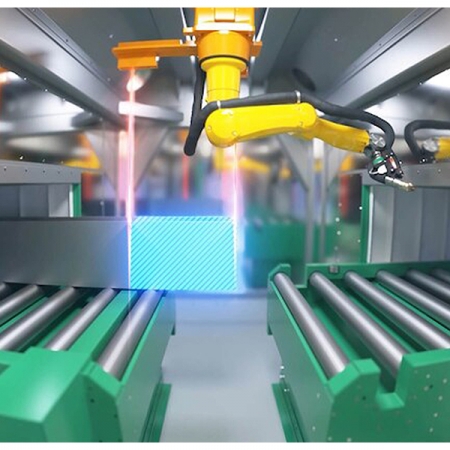

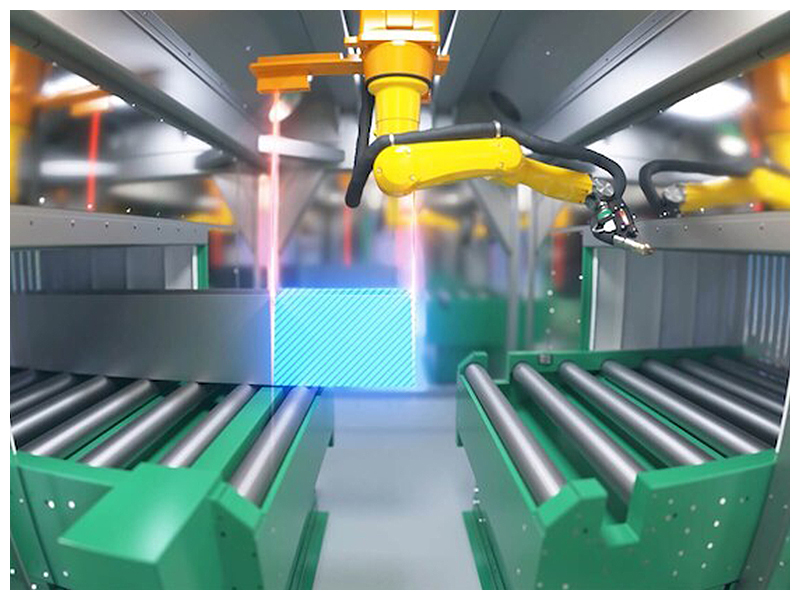

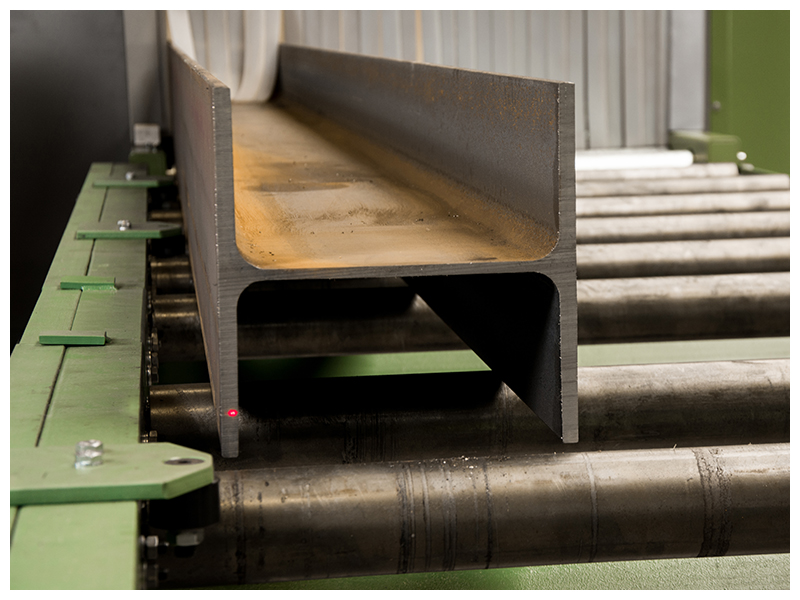

The Peddinghaus Peddibot-1200 Robotic Thermal Processor is designed specifically to revolutionize your beam cutting product. This advanced robotic technology takes innovation further with a scanning system that measures deviations in material and then adapts the robot’s cutting path to ensure perfect fitting – no probing necessary. The PeddiBot-1200, powered by HGG, is the future of plasma cutting production.

Why Peddinghaus Peddibot-1200 Robotic Thermal Processor?

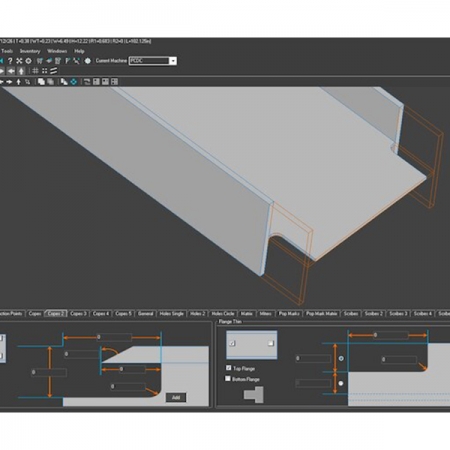

- Specialized torch movements throughout production on the Peddibot-1200 practically eliminate the need for grinding

- Operates burning and integrated layout marking on top and bottom flange web

- Utilizes a triangulation scanning system

- Minimizes overhead and human error associated with manual layouts by marking weld data onto a profile

- Eliminate the need for constant probing of material

- Streamline material handling

- Easily integrates into your existing Peddinghaus system

- Do the work of a drill line, coper, hand saw, and plate line all in one machine

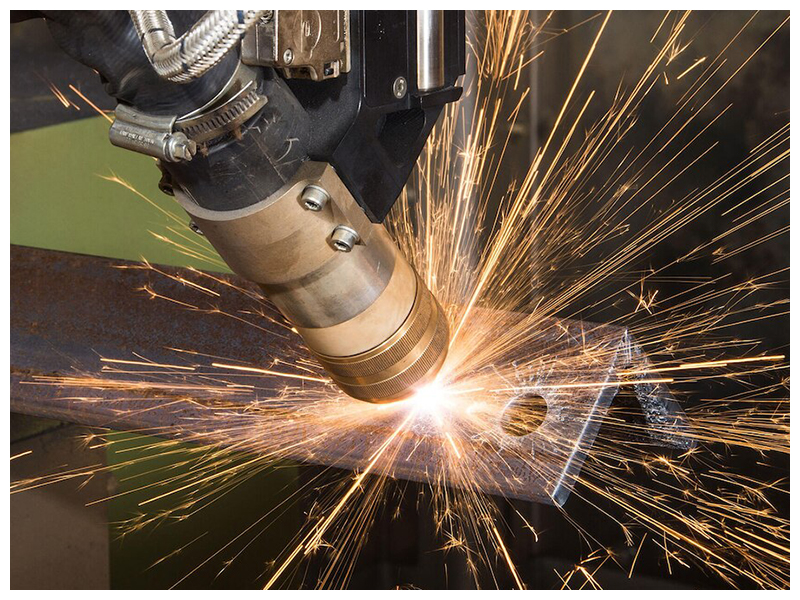

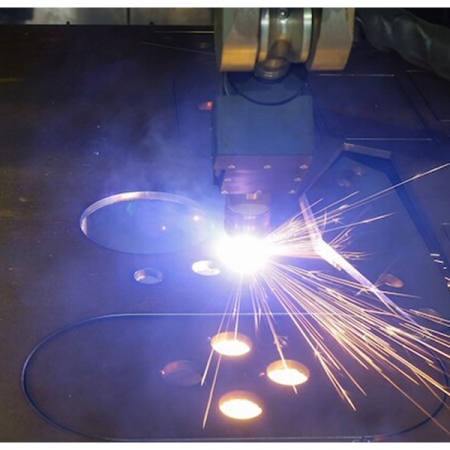

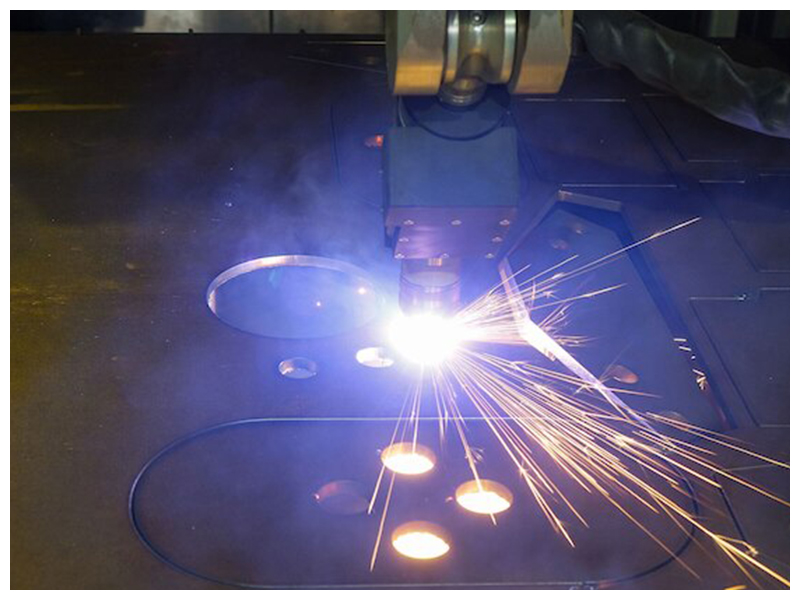

Robotic Plasma Cutting

The PeddiBot-1200 comes equipped with a Kjellberg HiFocus 440 amp plasma cutting system. The Kjellberg is designed to combine faster cutting speeds, rapid process cycling, quick changeovers and high reliability to maximize productivity. The system is capable of cutting up to 2″ (50 mm) thick steel and reaching speeds up to 70″ (1778 mm) per minute.

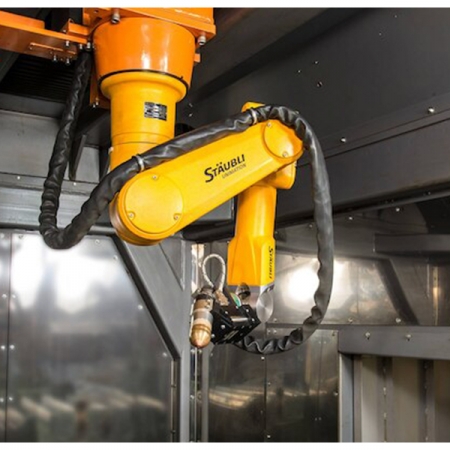

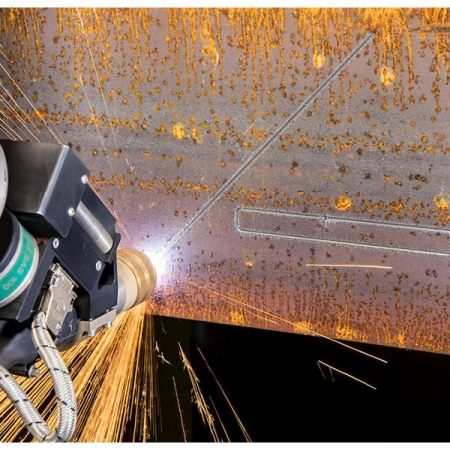

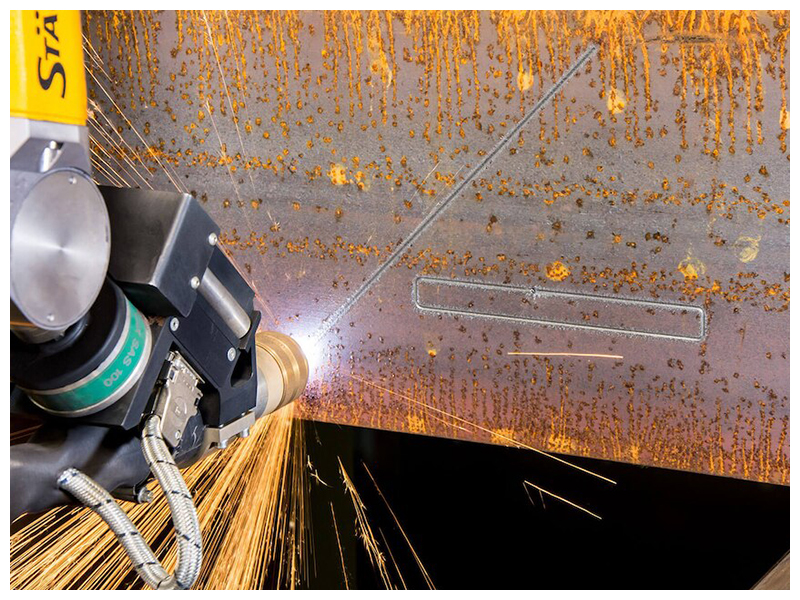

Staubli Robot for Cutting Intelligence

The plasma torch is positioned and controlled by a 6-axis industrial Stäubli robot arm. This rigid structure with metal casting allows for dynamic performance and stability during cutting and marking processes 360° around material. The highest level of accuracy is achieved throughout production due to the robot arm’s patented reduction gear system. This system provides unrivalled precision, flexibility and speed.

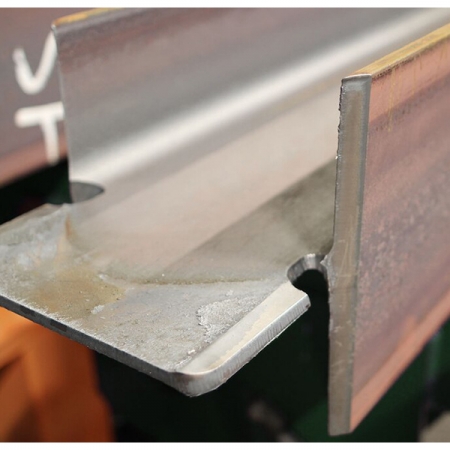

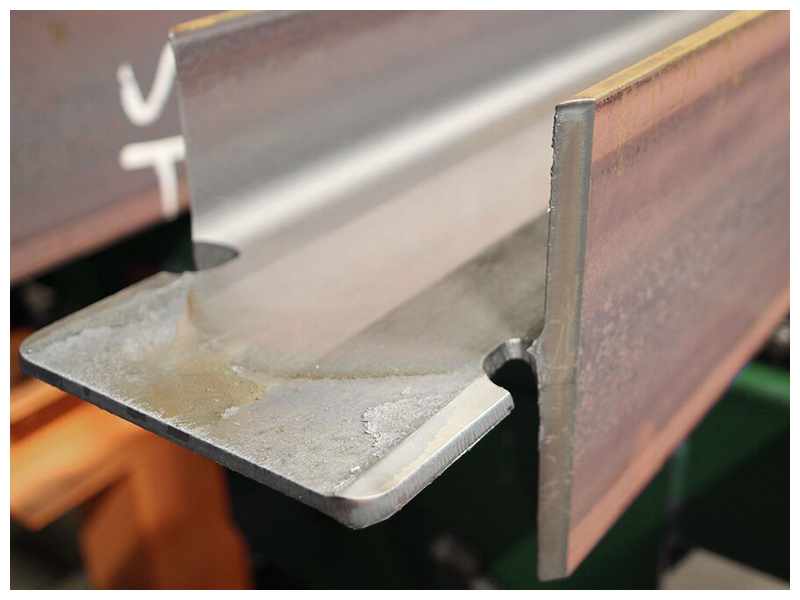

Near Flange Cutting

The most commonly used rathole within the structural steel industry cannot be completely cut by thermal cutting due to the plasma torch size. This requires manual grinding to cut away material without damaging the underlying flange. The PeddiBot-1200 applies a unique cutting technique that compensates the torch height position and tilts the torch backwards during the rathole cutting.

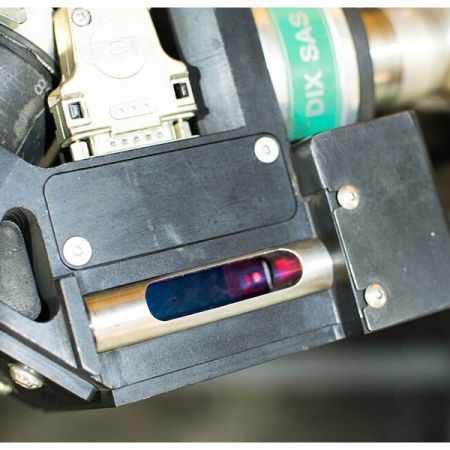

3D Triangulation Scanning System

The PeddiBot-1200 is equipped with a state-of-the-art measurement system to detect positional displacement and distortions of material. This intelligent system consists of a triangulation laser scanner for measuring sections. The material scanning is executed inside the cutting area and is performed in one, continuous cycle.

Integrated Layout Marking

Multi-axis plasma layout marking is a long-lasting and economical solution. Faster than carbide scribing and easier to maintain than a laser, the PeddiBot-1200 utilizes modern layout marking plasma technology. Completely visible through rust and scale, plasma layout marking technology reduces error from manual layout and marking weld data onto a profile

Dovetails, what’s the big deal?

Machinery SolutionsOnce you open the drawer and see the dovetail design, it elevates your product in the consumer’s eye. But why dovetail machine is right for my operation? When deciding to produce your own drawer boxes, a number of factors come into play when selecting the equipment required.

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.

Kingswood Cabinets. A true commitment to growth.

Case Study, Machinery Solutions, Service and SupportAkhurst is very proud of our involvement in the plant expansion of Kingswood Cabinets of Calgary, Alberta. Kingswood recently relocated to a new state-of-the-art manufacturing facility.