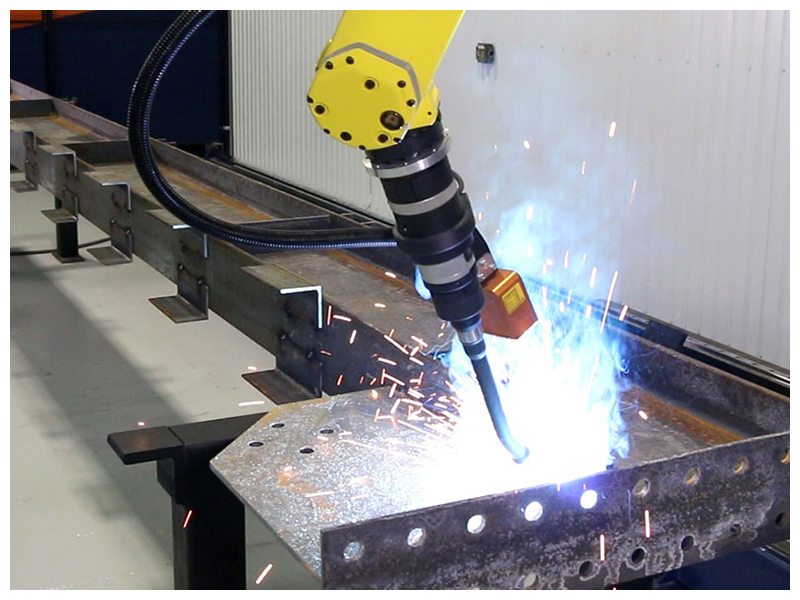

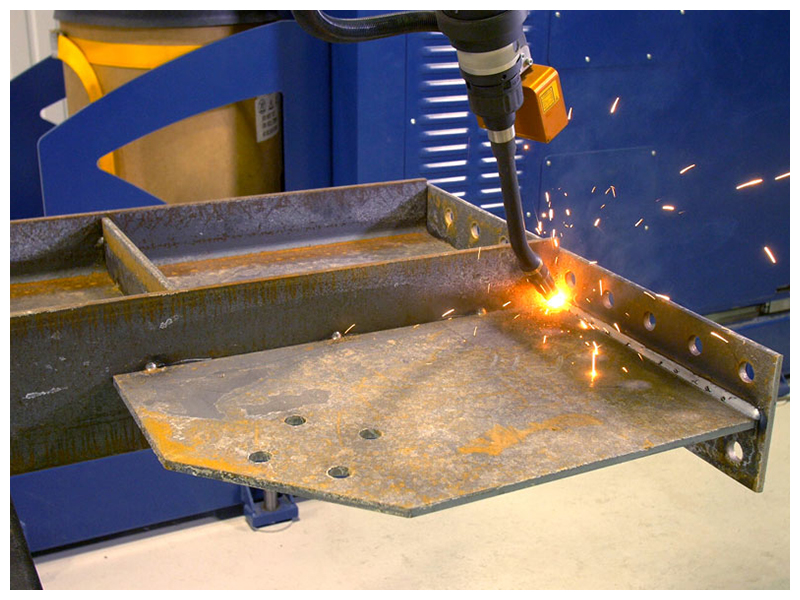

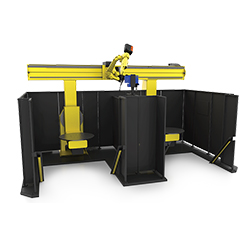

Fully Automated Welding of Attachments.

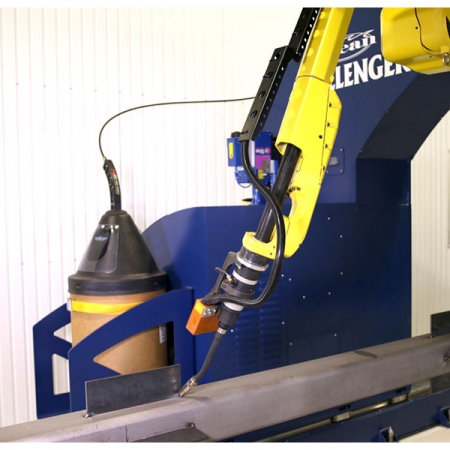

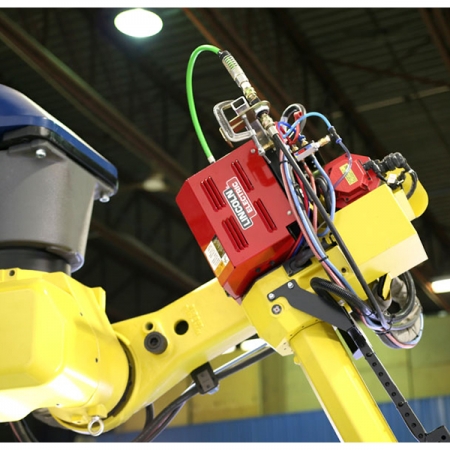

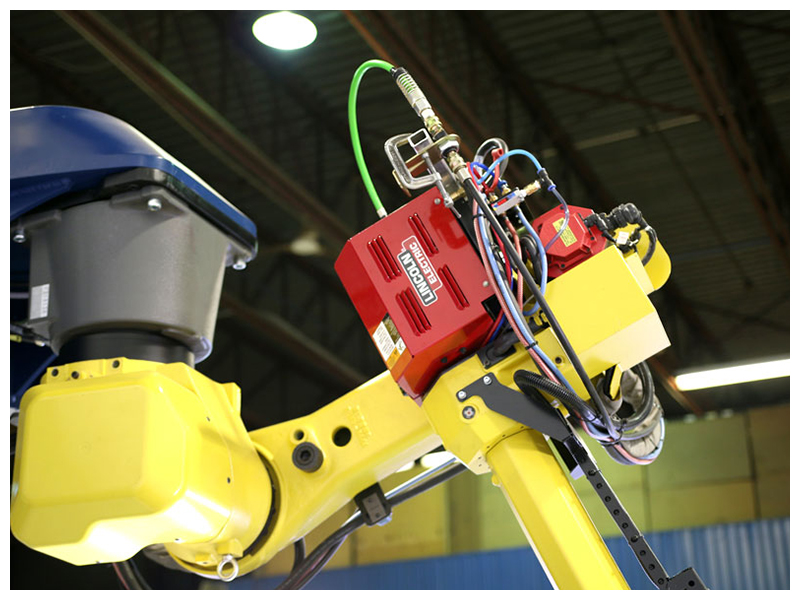

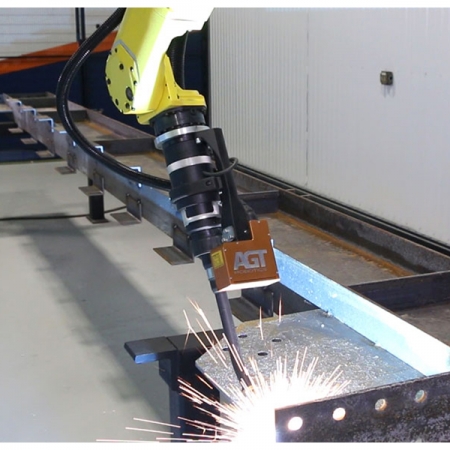

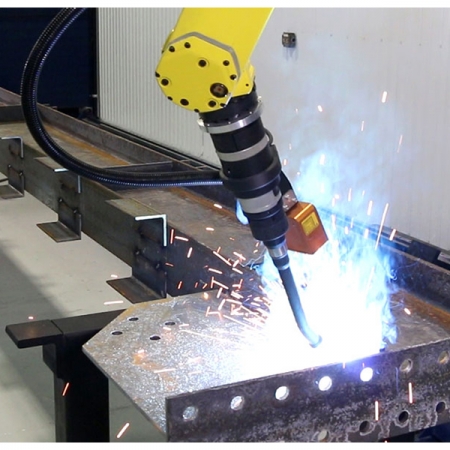

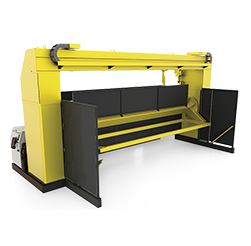

The Ocean Machinery Challenger Structural Steel Robotic Welder is a fully automated welding robot that welds attachments to beams and columns that have been tacked in place by the fitter. It is designed and built exclusively for Ocean by AGT, world leaders in robotic technologies. It is specifically designed for fabricators looking to increase production output and reduce labor costs. The compact footprint, fast robotic automation and easy to use software makes the Ocean Challenger welding robot the ideal solution for any size shop striving to be more efficient and cost effective.

Why Ocean Machinery Challenger Structural Steel Robotic Welder?

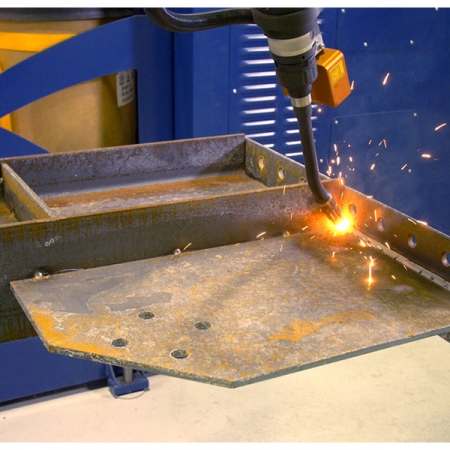

- Fully automated welding robot that welds attachments to beams and columns that have been tacked in place by the fitter

- Robots designed to work in the harshest conditions for years with minimal maintenance

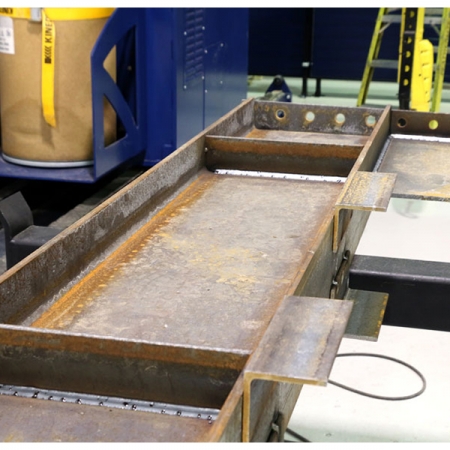

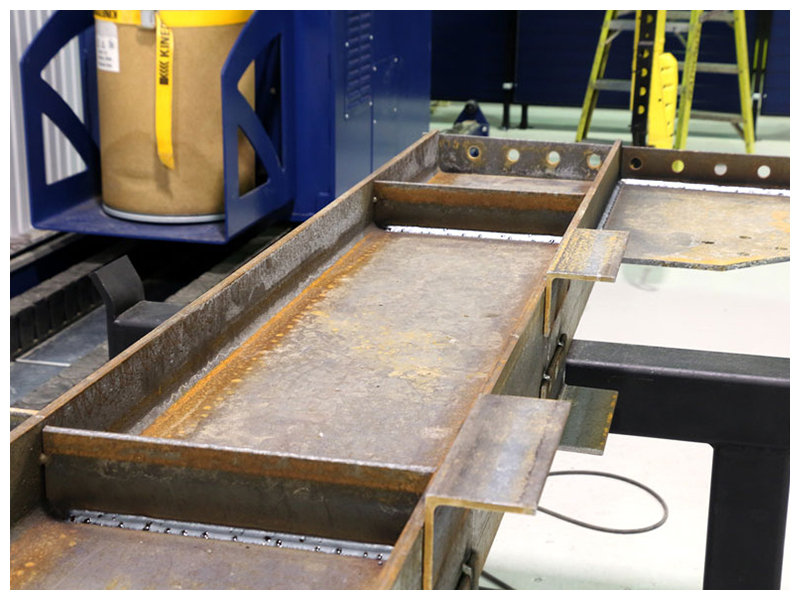

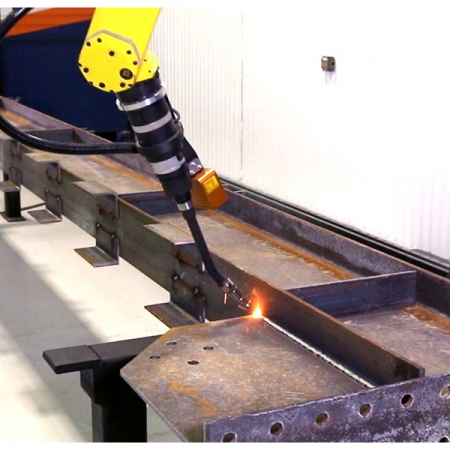

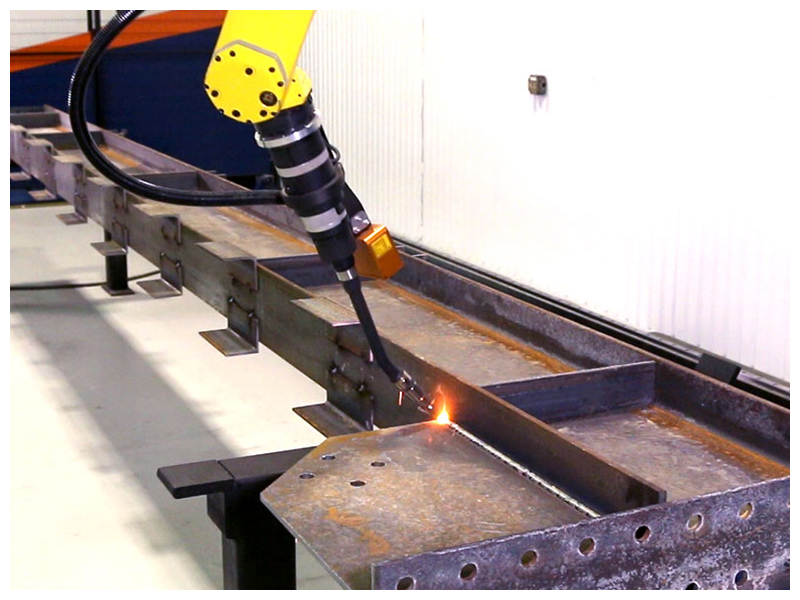

- Machine moves along a heavy duty rail while the part to be welded remains stationary

- Easy to use interface is provided to build production lists and monitor the production output

- Laser curtains ensure a safe working environment to the operator

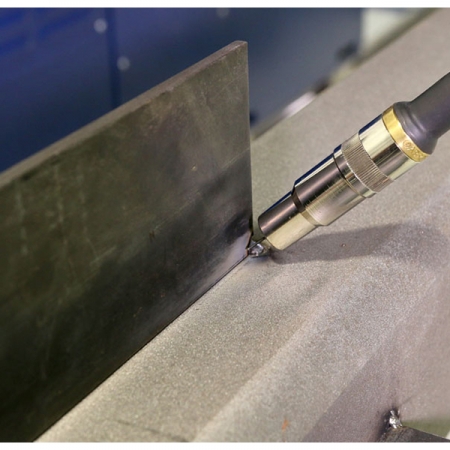

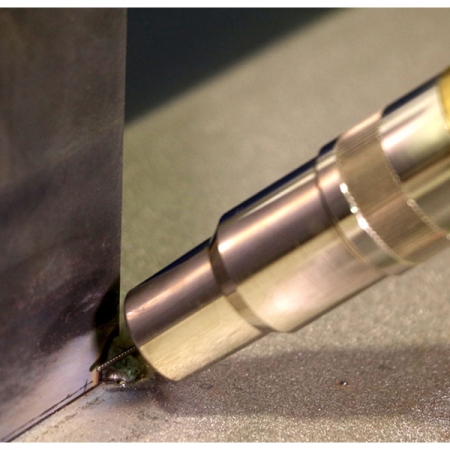

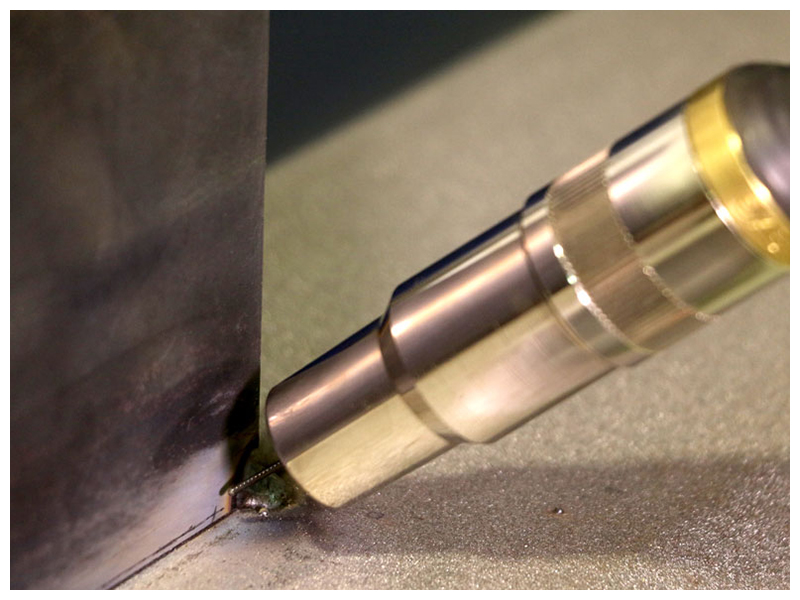

The Ocean Challenger Robotic Welder is a fully automated structural steel welding robot that welds attachments to beams and columns that have been tacked in place by the fitter.

AUTOMATED: The entire welding process is automated; the Ocean Challenger robotic welder only requires a fitter to tack the parts in place and position the beam or column into the production zone. The Ocean Challenger handles the mundane welding tasks by automatically welding the attachments to your beams and columns, allowing your experienced welders to work on more challenging projects.

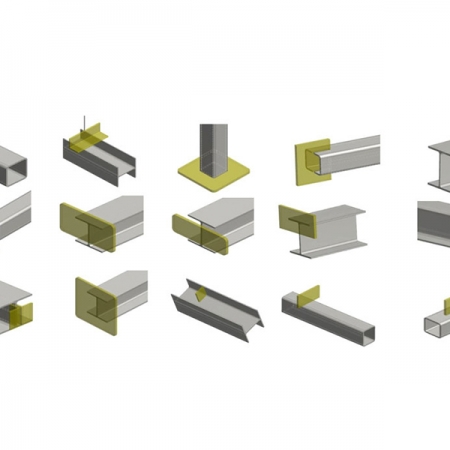

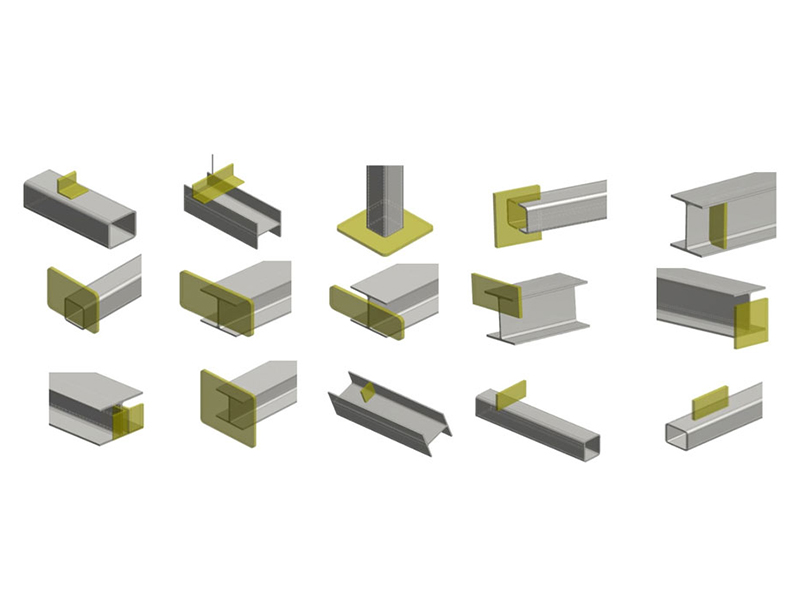

FLEXIBLE: The Ocean Challenger is designed for beams and columns up to 40” high, it is compatible with attachments such as angles, stiffeners, gussets, fin plates, base plates, end plates and other standard parts.

EFFICIENT: The Ocean Challenger welding robot is designed to fabricate most steel assemblies and attachments for structural steel, typically able to weld 75% to 95% of all attachments.

QUALITY: Robots are designed to work in harsh conditions for years with minimal maintenance ensuring consistent high-quality and repeatable results.

EASY-TO-USE: Compatible with Tekla & SDS2. Simply export the CAD model to the Ocean Challenger, run the simulation, select the exported simulation file using the Ocean Challenger’s user-friendly interface, load the part and start production!

SAFETY: The Ocean Challenger comes with a laser light curtain that automatically stops the machine when the perimeter is crossed, ensuring operator safety. Meets American ANSI/RIA R15.06-2012, and Canadian CSA Z434-14 safety standards.

SUPPORT: Any issues are handled directly by the experts at AGT. Most problems can be addressed quickly using remote web support with qualified technicians logging in remotely and accessing the machine interface & webcam so they can see what you see. For more complex issues a field technician can be dispatched to ensure you are up and running quickly.

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.