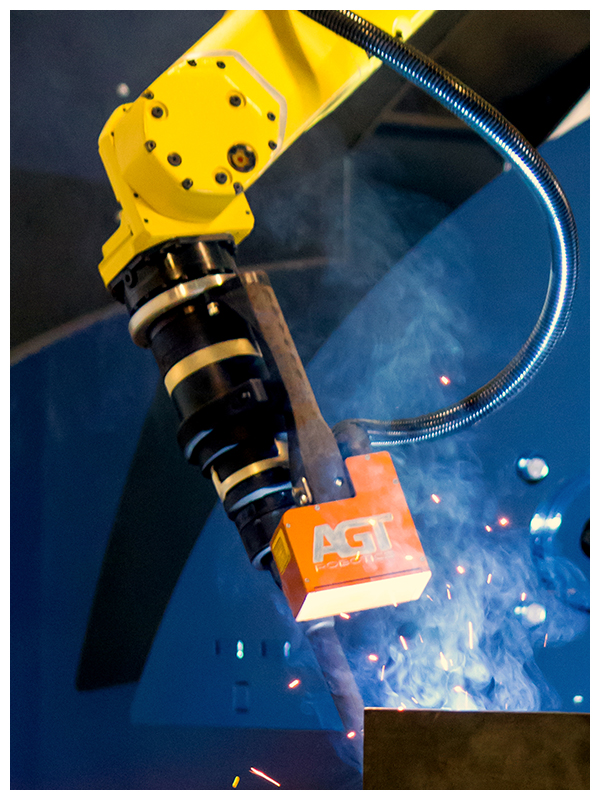

The common-sense, all-inclusive robotic welding solution for structural steel.

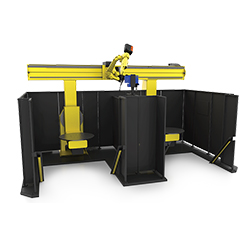

The AGT Robotics BeamMaster Robotic Steel Beam Welding System is specially engineered to answer all the welding needs of structural steel fabricators. BeamMaster WELD features a small footprint, complete robotic automation and integration with dedicated software. With our attractive prices, all sizes of fabrication shops can now consider solving their welding production issues with robotic welding.

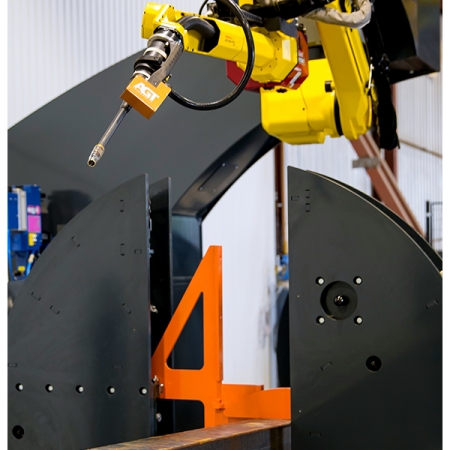

Simply send a pre-fit beam to the BEAMMASTER and watch it robotically complete the required welds in a fraction of the time it would take a manual welder. When equipped with the optional beam rotators, the entire sequence is completely autonomous as the robot automatically positions the welds into the horizontal position every time. Robotic welding has historically required a large volume of identical parts in order to be profitable. The BEAMMASTER’s award-winning CORTEX SOFTWARE makes robotic welding possible and profitable with lot quantities of one.

Why AGT Robotics BeamMaster Robotic Steel Beam Welding System?

AUTOMATED

No welders needed. It only takes a fitter to tack the parts in place and feed the assembly into the production zone. The entire welding process is automated.

EFFICIENT

The machine is designed to fabricate most steel assemblies and accessories. Robotic brings high-quality and repetitive results.

FLEXIBLE

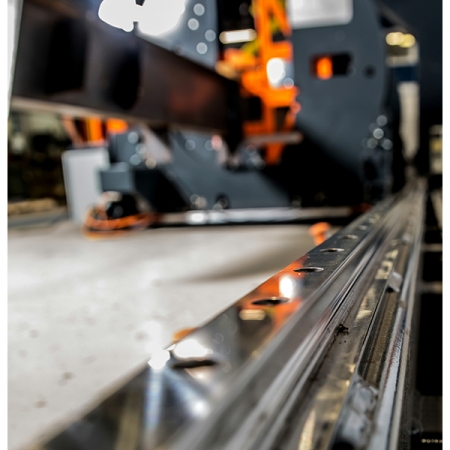

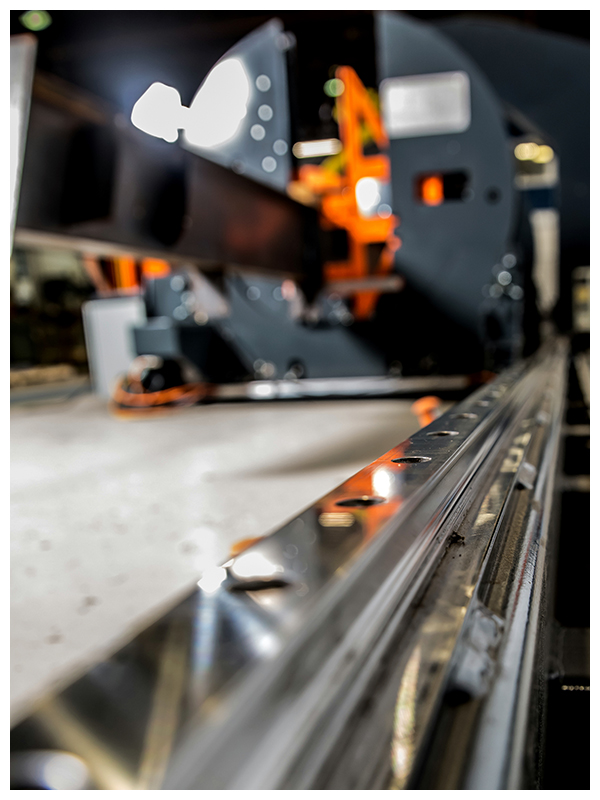

The BeamMaster WELD handles different weld types, which are defined by the 3D model or generated by the PartExpert module. It accepts W Beams, HSS profiles and even tapered beams. Compatible accessories include angles, stiffeners, base plates, end plates and other standard parts.

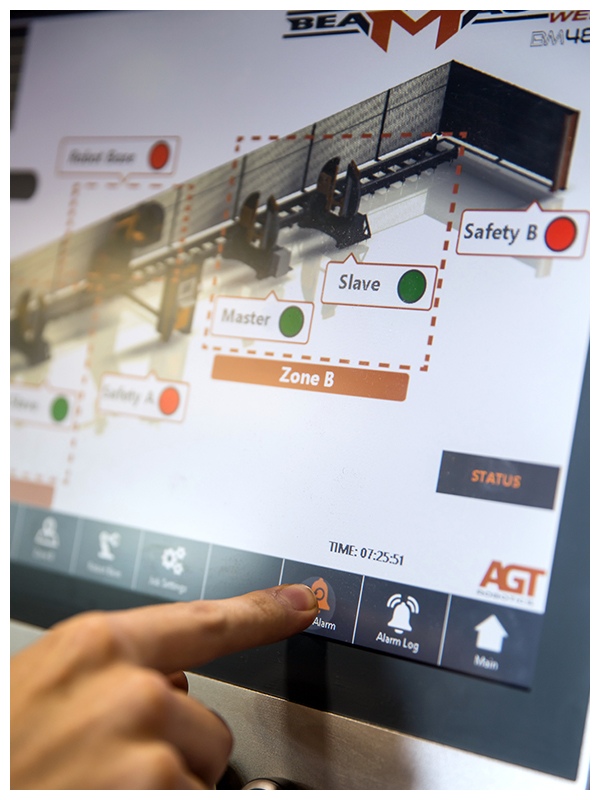

FAST SUPPORT

When needed, a dedicated team of professionals will help you maximize the power of this cutting-edge technology. Most questions and issues can be addressed within minutes using remote web support. Our qualified technicians can log in remotely and access the interface, so they can see what you see. Field technicians can also be on site to ensure proper maintenance and/or repairs.

- Increased Production – Automated production flow from CAD to production

- Consistent high quality and repetitive results

- Completely automatic operations, resulting in no more labour shortages and ability to reassign current welders to complex tasks

- Optimized cycle time (2 work zones) – fitter can tack another beam while robot is welding

- Small footprint

- Welding program is offset to adjust to fitting tolerances – adaptable and works with non-perfect parts

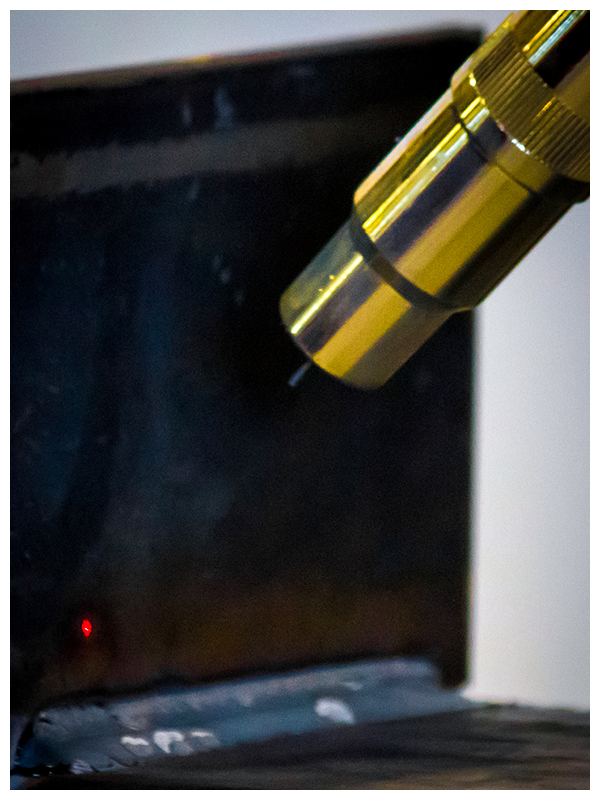

- Joints are found by laser sensor and welding robot program is offset based on the position