Industrial filling technology.

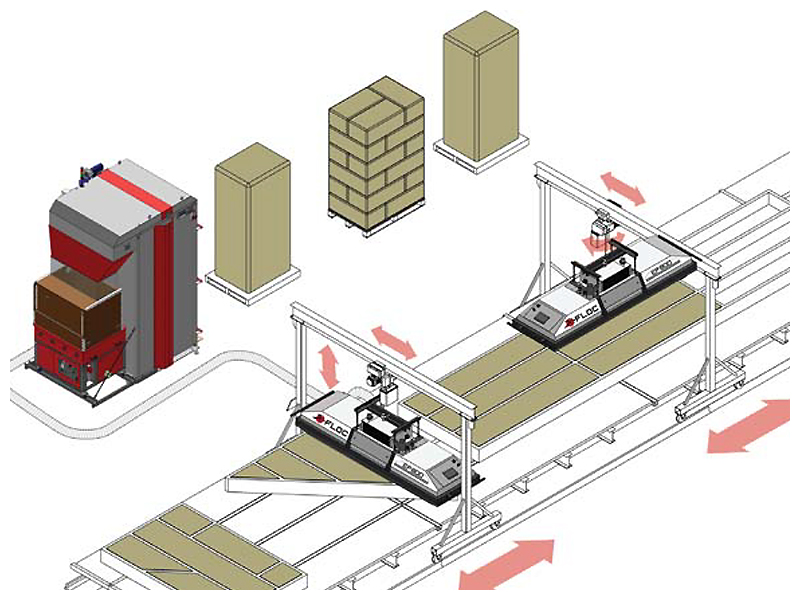

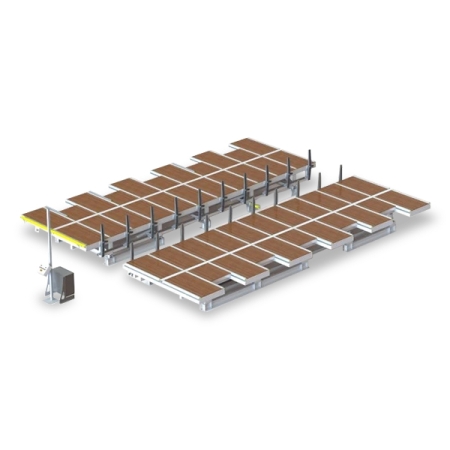

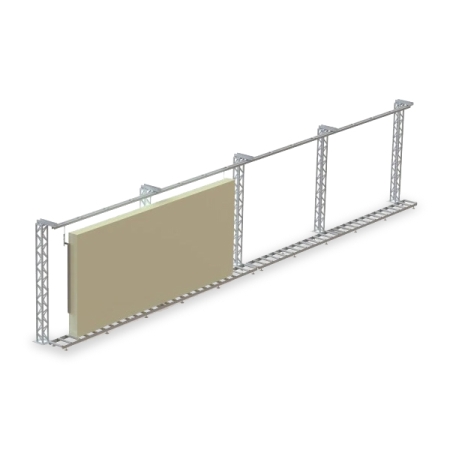

The MBA X-Floc Insulation Blowing Machine with X-Fill Bridge System is a fully automatic system used to fill prefabricated wall panels with cellulose, wood fibre, glass/rock wool, as well as composite materials. The X-Fill system is capable of filling any size or shape cavity due to the modular construction of the blowing plate and each filling operation takes a matter of seconds. This is done by simply entering the dimensions of the wall panel into the 17” touch screen where the full PC control calculates the volume of material needed to fill the cavity.

Why the MBA X-Floc?

- Joystick controlled positioning or full PC control with 17” touch screen

- Interactive display of operation being performed

- Automatic download from drawing software

- Heavy-duty tables with one fixed side and one moving side

- 90-degree squaring corner blocks with pneumatic retraction to enable the panel to move to the next position when finished

- Motorized table opening with automatic brake locking

- Customizable density control of the insulation

- Variable cavity size

- X-Floc EP800 blowing plate: Controlled by a high-quality industrial controller “Made in Germany” and software developed by X-Floc. After placing the blow-in panel on the unplanked element on one side, only the dimensions (length, width, height) and the insulation material used need to be entered, after which the blow-in process can be started.

- X-Floc EP1050 blowing plate: Injection module for automatic element filling with loose insulation material

- X-Floc bale conditioning machine: Used to process delivery bundles, which, depending on the manufacturer, consist of compressed insulation material blocks of the appropriate size or stacked insulation material bales. Ideal for stationary factory use and, together with an insulation blowing machine plus injection panel, forms the basis for the highly efficient filling of prefabricated wall and ceiling elements.

- X-Floc insulation blowing machine: Very high compatibility with all insulation materials available on the market (cellulose, wood fibre, mineral wool, granulates, bulk materials, composite materials, etc.). X-Floc offers the user the greatest possible flexiblity to act with regard to the requirements of the building project as well as to changes in the market.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.

Dovetails, what’s the big deal?

Machinery SolutionsOnce you open the drawer and see the dovetail design, it elevates your product in the consumer’s eye. But why dovetail machine is right for my operation? When deciding to produce your own drawer boxes, a number of factors come into play when selecting the equipment required.

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.