Double your production speed with the Maggi double row line boring machine.

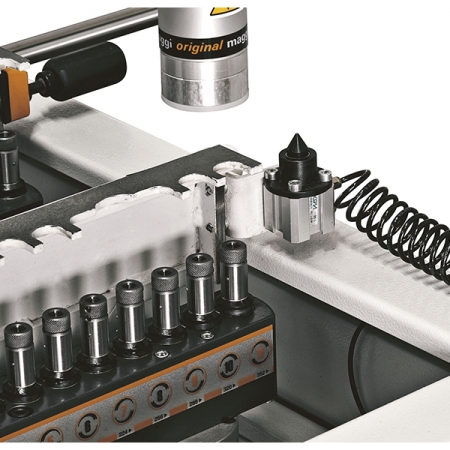

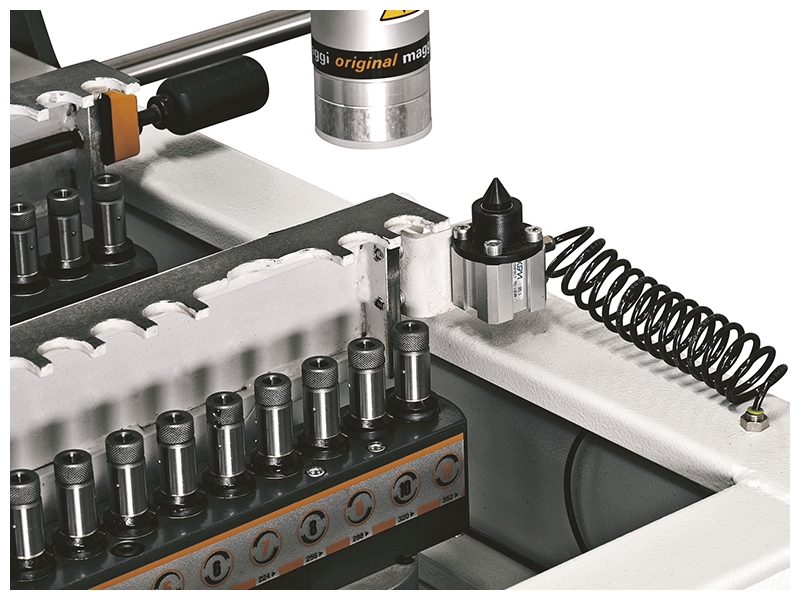

The Maggi System 46 Double Row Line Boring Machine is a semi-automatic boring machine that is equipped with two parallel vertical boring heads for vertical boring, expressly designed to execute holes in a line and particularly suited for closets, wardrobes, and bookcase side processing.

Why Maggi System 46 Double Row Line Boring Machine?

- Quick, precise, and easy setting-up

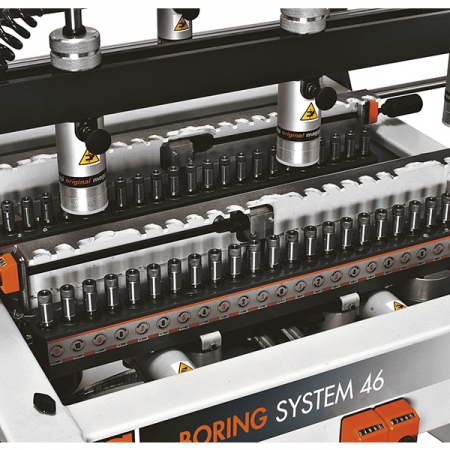

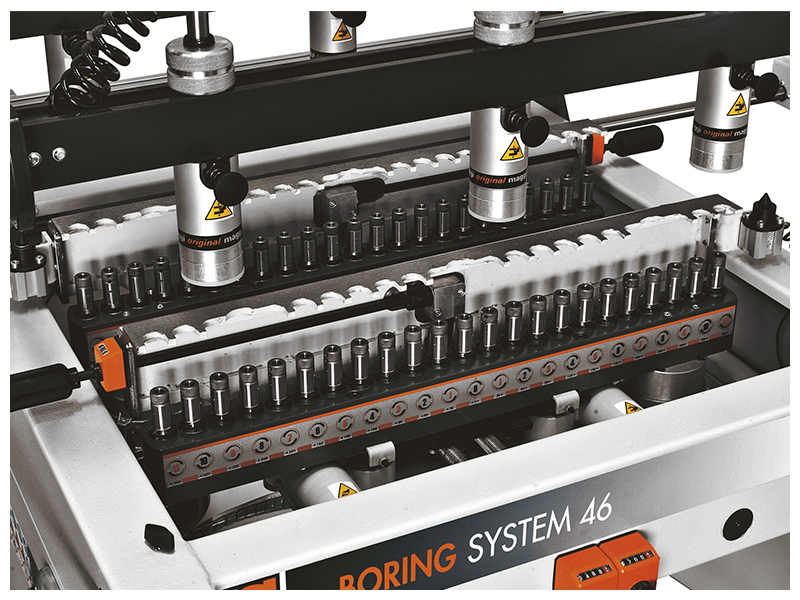

- Two 23-spindle boring heads on 32mm centers

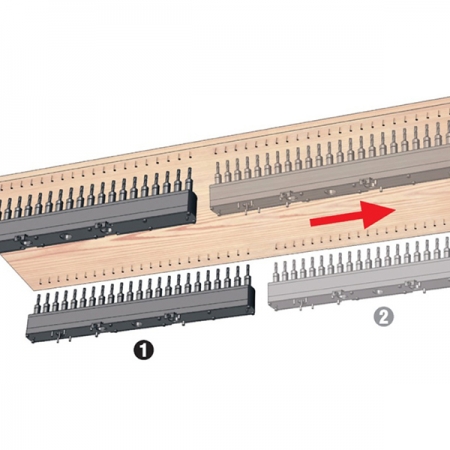

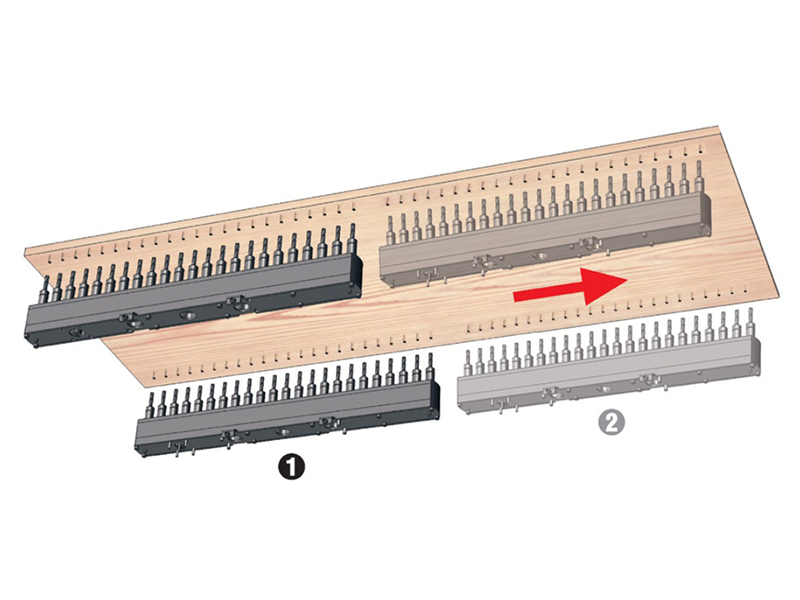

- One fixed and one movable boring unit with accurate adjustment by precision digital counter

- (2) pneumatic index referencing pins for continuous line boring pattern with absolute precision

- Quick change chucks for setting boring pattern

- Pneumatic foot pedal operation keeps your hands free for handling the workpiece

- Mechanical readout for accurately adjusting the moving drill head

KEY FEATURES

- Bore depth adjusted by hand wheel and read with digital counter

- Patented material clamps (6) allow for fast setting on top of the panel without any further adjustment required

- Extendable support rollers on both sides to help support longer gables or sides

- 3000 x 80 mm aluminum back fence with (4) flip stops for accurate boring hole positioning

- (46) quick change chucks

- CSA electrical components

SPECIFICATIONS

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.