An essential in any artisan carpenter’s workshop.

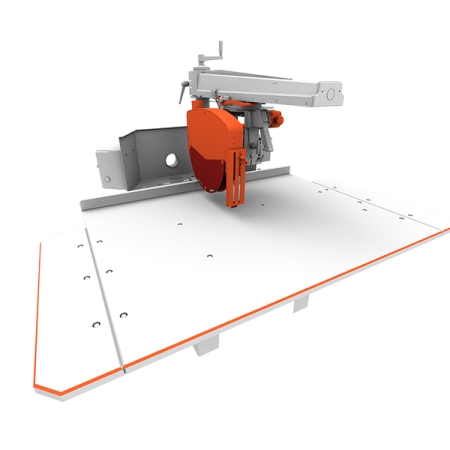

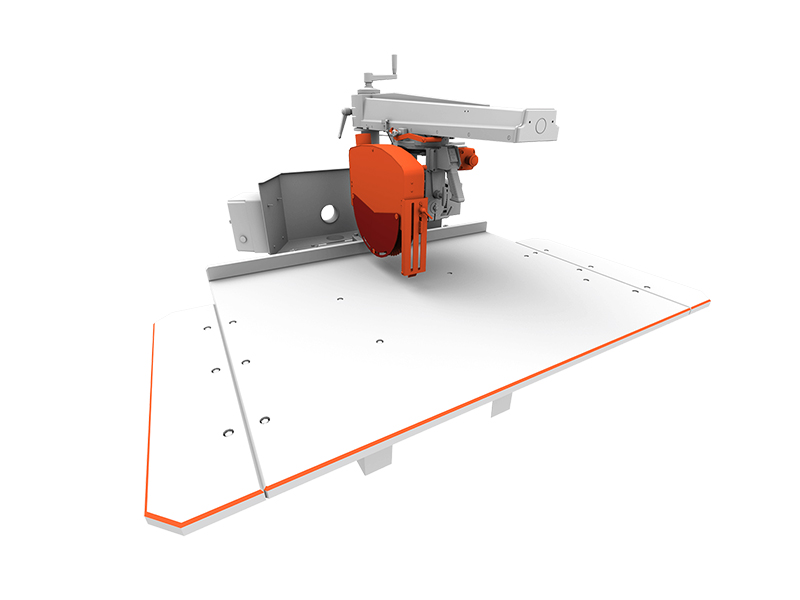

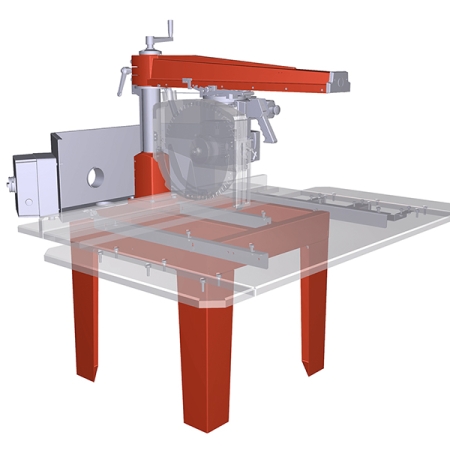

The Maggi Junior 640 radial arm saw offers adaptability, versatility, precision and durability to shops of all sizes. Maggi has been producing radial arm saws since 1973 and over the years has continually improved technical design and quality. Heavy castings and the eight bearing saw carriage makes this machine very accurate and rigid. European quality made to last!

Why Maggi Junior 640 Radial Arm Saw?

- Powerful 4HP motor (3-phase) or 3HP (1-phase)

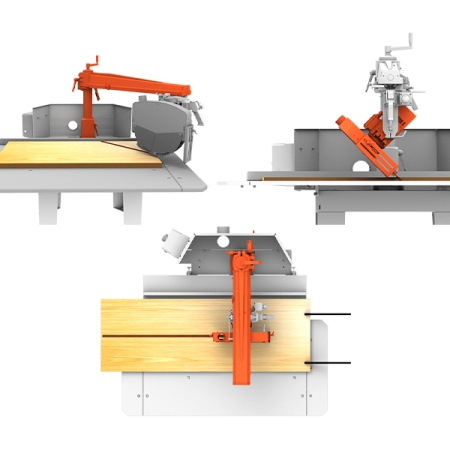

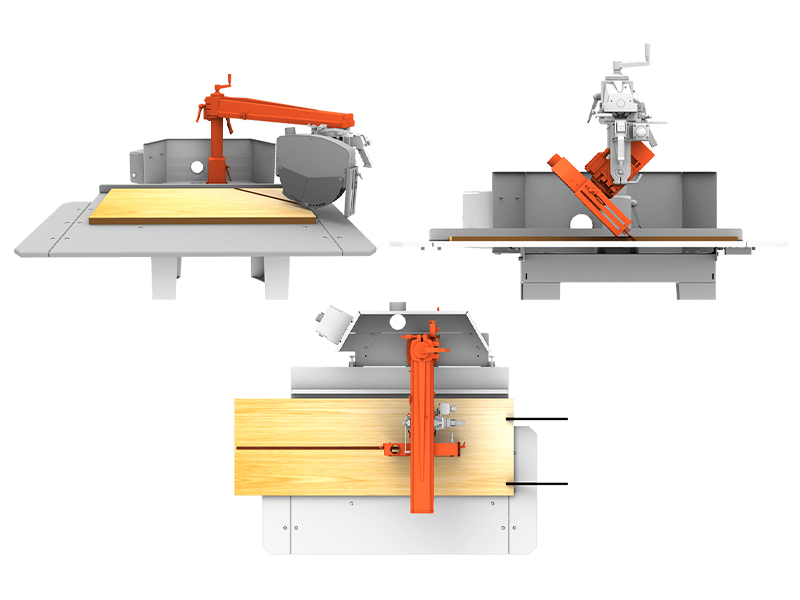

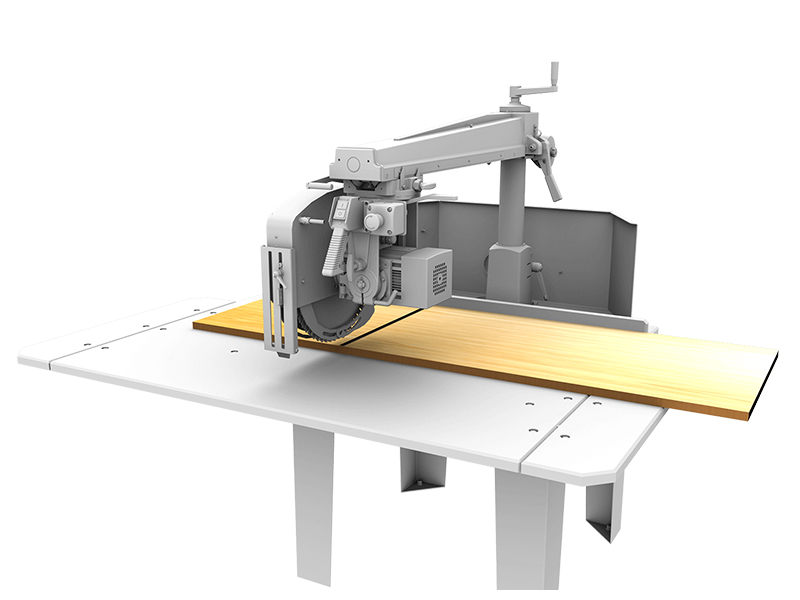

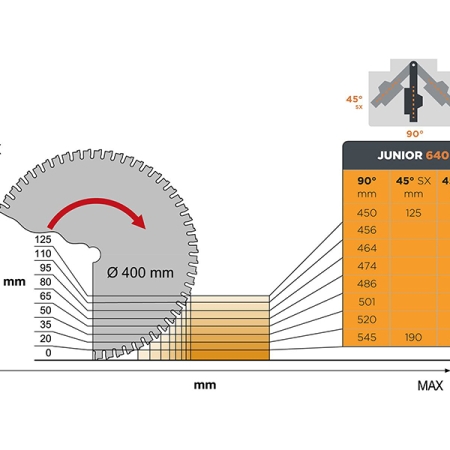

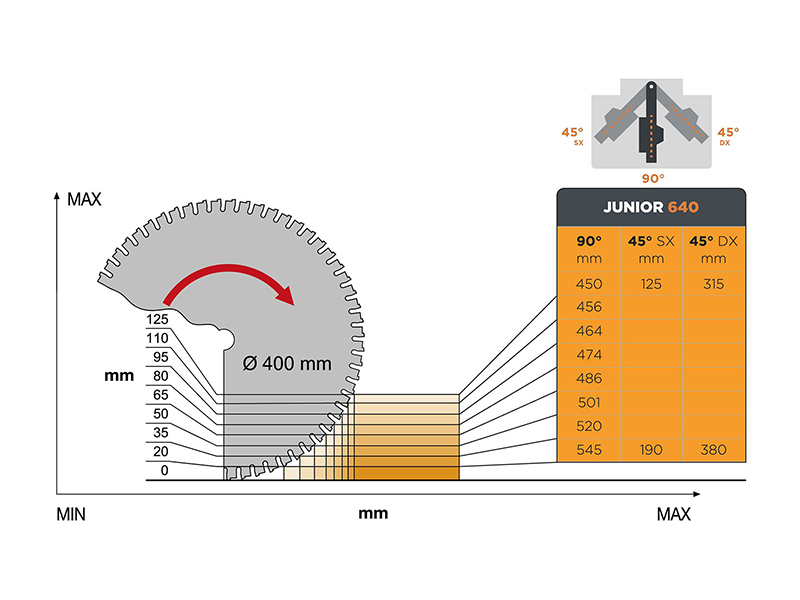

- Versatile design where the arm can swivel left and right to 45o for mitre cutting, the saw unit can tilt to the left to 45o for bevel cutting, and the saw unit can rotate to 90o for rip cutting.

- Small footprint : well suited to small workshops

- Easy to use

- Safe to operate with blade guard and anti-kickback device

- Rugged steel frame construction with cast-iron arm and back for superior durability

VERSATILE

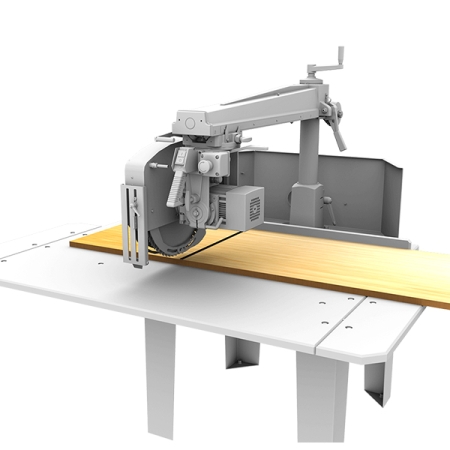

Swivelling arm up to 45° left and right and left tilting cutting-head (stop and lock at 45°) allow many different cutting operations for the greatest versatility. The cutting-head can also turn by 90° for accurate ripping.

SAFE

Sound-insulated, full-cover blade guard with safety microswitch, antikickback, well-dimensioned working bench, emergency button and pushsticks definitively contribute to the operator safety during the cutting process.

SOLID AND ACCURATE

Rugged steel construction, arm and base made of cast iron. Interchangeable and tempered-steel made guides. Cutting head sliding on 8 ball bearings for a smooth, precise and effortless carriage mouvement.

THE MOST POPULAR

Cutting width up to 545 mm. All-around performance. Well-suited also for the hobbyist.

Dovetails, what’s the big deal?

Machinery SolutionsOnce you open the drawer and see the dovetail design, it elevates your product in the consumer’s eye. But why dovetail machine is right for my operation? When deciding to produce your own drawer boxes, a number of factors come into play when selecting the equipment required.

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.

Kingswood Cabinets. A true commitment to growth.

Case Study, Machinery Solutions, Service and SupportAkhurst is very proud of our involvement in the plant expansion of Kingswood Cabinets of Calgary, Alberta. Kingswood recently relocated to a new state-of-the-art manufacturing facility.