Designed for residential or commercial door shops needing to bevel and prehang door units or machine slab doors.

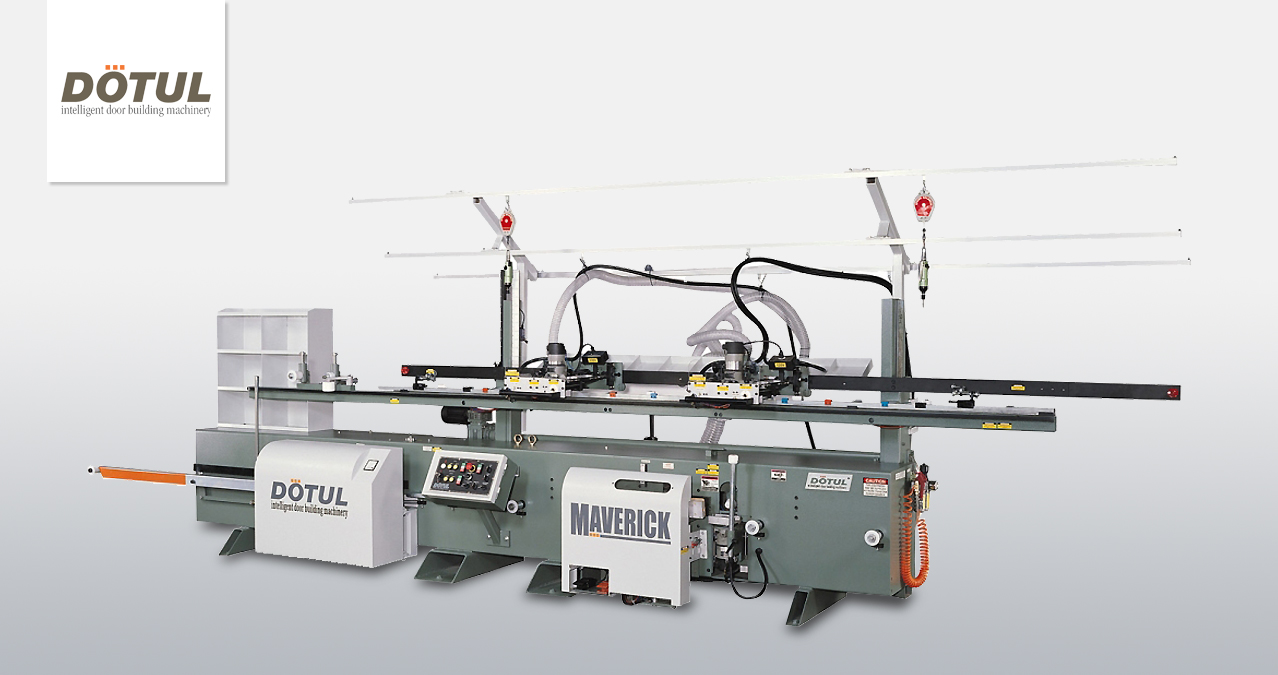

The Dotul Maverick DT-500 Prehung Door Machine is a vertical door machine that has been designed and built by door machinery specialists with over 100 years of combined machinery, door and millwork experience.

The Maverick door machine is ideal for residential or commercial door shops that need the versatility to pre-hang door units or machine slab doors. Standard features of the Maverick allow for machining of a 4-0 to 9-0 door unit with raised moulding on both sides of the door. Width control adjustments are easily made from a centralized control panel, allowing for pinpoint accuracy. Dotul machinery is built tough from the frame up, incorporating numerous design features that allow for easy maintenance of movable parts and special features that allow the operator to machine a wide variety of doors.

Why Dotul Maverick DT-500 Prehung Door Machine?

- Designed for versatility and flexibility.

- Designed to prehang wood, fiberglass and residential steel doors with wood edges.

- Can machine door widths from 1-6 to 4-0 width by 9-0 in height, 1 3/8”, 1 ¾” and even 2 ¼” thick doors.

- Applicable for entry-level shops or large shops that need the versatility to machine and prehang a wide variety of door and hardware types.

- Built tough like all DOTUL products and the design is simple but functional.

- Standard features on the MAVERICK include automatic width indexing and lock and latch boring functions

- 4-Knife Cutterhead – Produces a smoother more consistent bevel especially on hardwoods and reduces the chance of sniping at the end of the cut.

- Cutterhead Load Meter – Visual cue to the operator to make powerfeed wheel speed adjustments on heavy or dense material doors to improve quality of cut.

- Centralized Control Panel – Reduces steps and increases the operator accessibility to the controls.

- Narrow Sidelites – Easily insert rollers to machine 1-0, 1-2, and 1-4 sidelites. Eliminating the need and hassle of blocking the sidelite with a shim.

- Enhanced Dust Collection – Round dust collection piping is channeled to all cutting areas, reducing the chances of cookies getting stuck and affecting the efficiency of the dust collection.

- Heavy Duty Frame Construction – Reduce the chance of the machinery twisting or being damaged. Forklift pockets and dual pickup points make the machine easy to move and reposition for different shop layouts.

- Finite Width Indexing – Fast or slow width adjustments made easily from the centralized control panel.

- 5-Position Jamb Clamping – Allows for machining of 3-0 and 4-0 jamb lengths and helps straighten longer 6-8 to 9-0 jambs prior to machining for the hinge pocket.

- Bolt on wear strips – Will last longer and will not peel off at the ends or middle of the wear strip.

- Infeed bed rollers – Makes it much easier to feed the large heavy architectural doors

- Auto adjust power feed wheels – Easier to go from 1 3/8″ to 2 1/4″ thick doors

- New improved butt router – 1 3/4 HP Dewalt 616 router motor – Lower maintenance, easier on the operator and quick change over.

- Auto backset from 2 3/8” to 2 3/4″ – Faster and more accurate

- Quick change from square to bevel on the faceplate router – Better finish quality on the faceplate, no more high and low side on the faceplate.

Dovetails, what’s the big deal?

Machinery SolutionsOnce you open the drawer and see the dovetail design, it elevates your product in the consumer’s eye. But why dovetail machine is right for my operation? When deciding to produce your own drawer boxes, a number of factors come into play when selecting the equipment required.

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.

Kingswood Cabinets. A true commitment to growth.

Case Study, Machinery Solutions, Service and SupportAkhurst is very proud of our involvement in the plant expansion of Kingswood Cabinets of Calgary, Alberta. Kingswood recently relocated to a new state-of-the-art manufacturing facility.