Production 7.5 HP sliding table shaper.

The Cantek SS512CSB sliding table shaper is a ruggedly built sliding table shaper with refined features well suited for demanding production environments. Its’ versatile design makes it the ideal shaping solution for edge-profiling, door & furniture components, mouldings, tenoning, and more. The sliding table is cast iron and runs on bearings for smooth and vibration free movement. The powerful dual direction 7.5HP driven spindle allows for optimum shaping even with large profiles. The heavy-duty cast-iron table and shaping column ensure maximum stability with superior vibration damping for optimum finish quality.

Why Cantek SS512CSB Shaper?

- Cast iron sliding table runs on bearings for vibration free and smooth movement

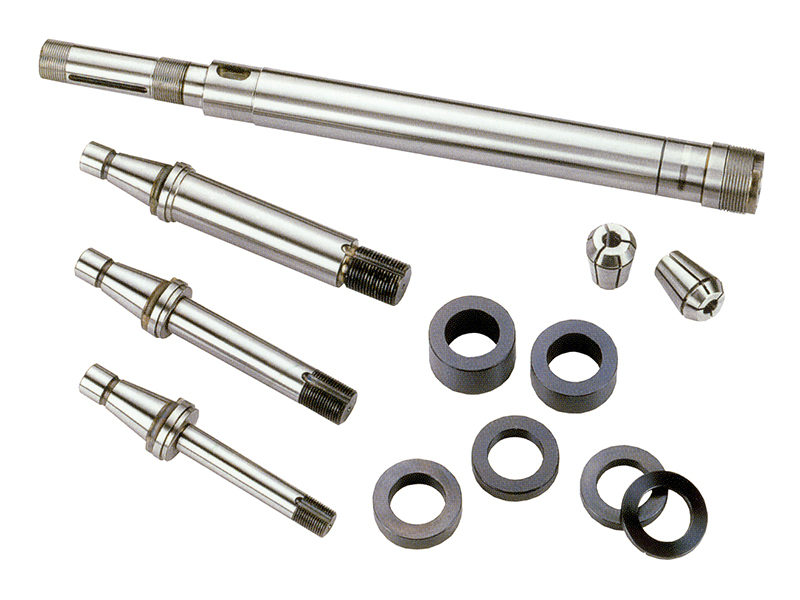

- 1 ¼” interchangeable spindle is standard (other sizes available)

- Large cast-iron table is ground and polished for maximum stability and durability

- Powerful 7.5 HP motor for even the most demanding profiling work

- Five spindle speeds can be easily adjusted to suit your tool diameter

- Electronic spindle brake for added safety and facilitates with fast changeover

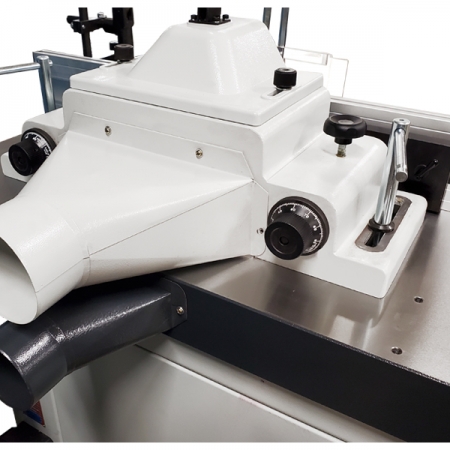

- Precision fence assembly with micro infeed and outfeed fence adjustment

- Finger style fence allows fence to be adjusted around the cutter for added safety and workpiece stability

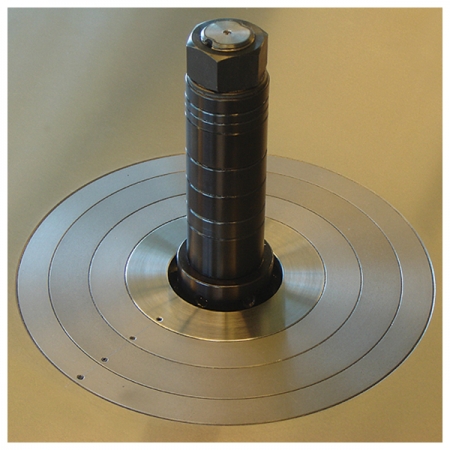

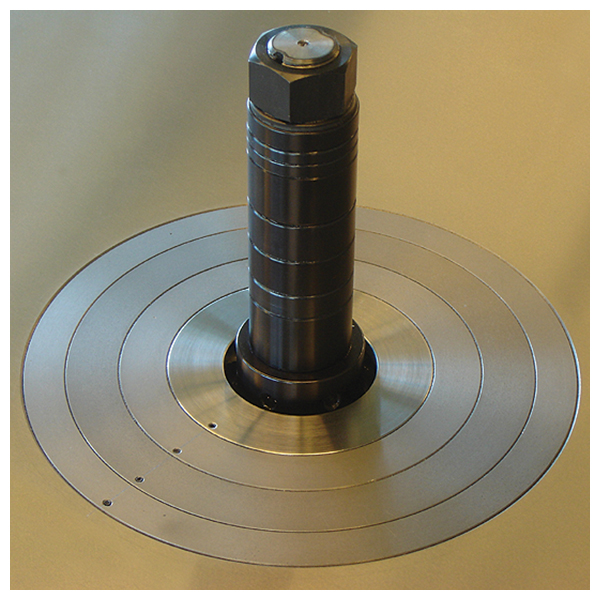

- Cast iron ground & polished table with insert rings & t-slot for mitre / tenoning jig

- Precision ground and electronically balanced spindle

- V-belt drive with (5) spindle speeds is easily accessed from the front of the machine (3/4/6/8/1000 RPM)

- Electric spindle brake for added safety

- Spindle lock – with limit switch safety, machine will not start with lock engaged

- Micro spindle height adjustment with dial indicator for precise height adjustment

- 1 ¼” Interchangeable cutter spindle is standard

- Forward/reverse spindle rotation

- Adjustable “finger” type fence

- Independent micro-fence adjustment on both sides

- Plug to accept Cantek Power Feeder and table is pre-drilled for mounding feeder base

- Includes the following standard equipment:

- 1 ¼” spindle

- (1) 5” dust chute on guard & (1) 4” dust chute in the table

- Safety guard

- Mitre tenoning jig

Dovetails, what’s the big deal?

Machinery SolutionsOnce you open the drawer and see the dovetail design, it elevates your product in the consumer’s eye. But why dovetail machine is right for my operation? When deciding to produce your own drawer boxes, a number of factors come into play when selecting the equipment required.

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.

Kingswood Cabinets. A true commitment to growth.

Case Study, Machinery Solutions, Service and SupportAkhurst is very proud of our involvement in the plant expansion of Kingswood Cabinets of Calgary, Alberta. Kingswood recently relocated to a new state-of-the-art manufacturing facility.