Easy Controls, Easy Setup, Easy Quick-Change Head, Easy Coping.

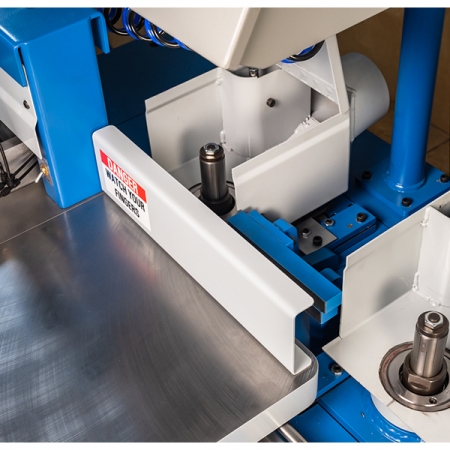

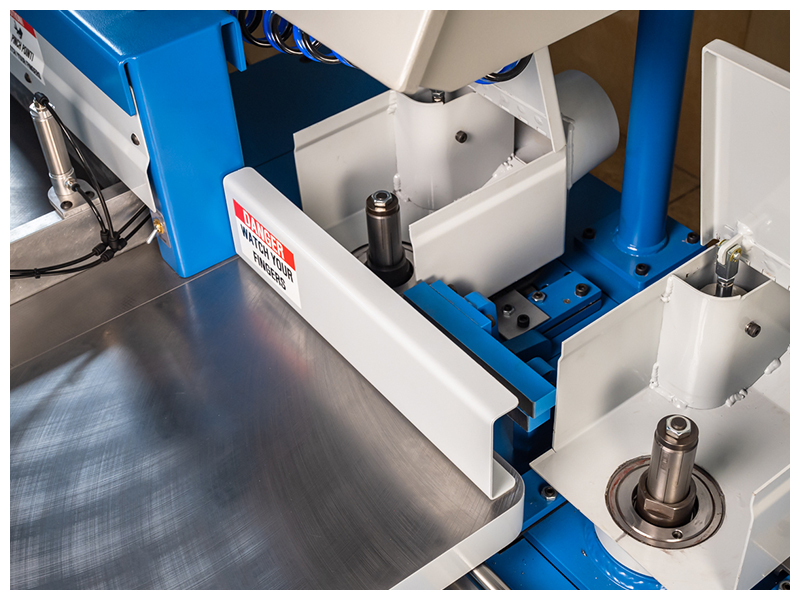

The Circle T C220 Two Head Coping Machine simplifies the end-coping process for cabinet doors. It is designed for users buy mouldings or profile the rail on a moulder, then end-cope. Easy quick-change spindles are included with the machine to make tool changes EASY

Why Circle T C220 Two Head Coping Machine?

- Two quick-change spindles

- Y and Z axis adjustments with digital readouts

- Foot pedal cycle start

- Pneumatic hold-down clamp system

- 3” and 4” ID heads compatible

KEY ADVANTAGES

- 16″ wide cutting capacity

- 5/8″ to 1″ material thickness

- High speed table with optic load sensor for quick cycling

- Controls located on front side of machine

- Flat belt drive

- No vibration guaranteed

- No tool holders needed – use your current heads on the quick-change spindles

- No tear-out

SPECIFICATIONS

Akhurst Machinery Group announces strategic partnership to aid North American housing crisis.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the North American machinery industry, is pleased to announce a strategic partnership with Modular Building Automation (MBA), a Dutch company specializing in machinery for prefabricated homes, modular buildings, and offsite construction solutions. MBA, a joint venture of the renowned companies J.J. Smith in the UK and Ireland and H&M headquartered in the Netherlands, is involved in the design, manufacturing, distribution, and worldwide sales of MBA equipment.

Akhurst Machinery Group announces strategic partnership with Stromab.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the machinery industry, proudly announces a strategic partnership with Stromab SPA, an Italian manufacturer of innovative crosscutting solutions. This collaboration signifies a major commitment by both companies to bring cutting-edge technology and comprehensive solutions to the North American market. Akhurst Machinery Group, the parent company behind the well-known brands of Cantek and Leadermac USA, will leverage Stromab SPA’s expertise in crosscutting solutions to enhance its offerings in North America.

Woodworking Technology Days 2023 is just around the corner.

Corporate, Machinery Solutions, Trade ShowsVisit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.